Preparation method of calcium-magnesium-silicon multiphase ceramic coating for titanium-based artificial joint handle

A technology of artificial joint and ceramic coating, applied in the direction of coating, can solve the problem of low bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

[0021] The present invention will be further elaborated below in conjunction with the specific examples given by the inventor. It should be noted that the present invention is not limited to this embodiment, and those skilled in the art can add and replace technical features within the scope of the present invention, all of which belong to the protection scope of the present invention.

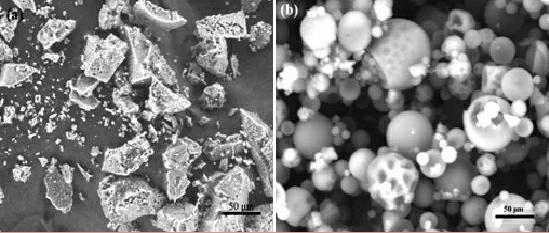

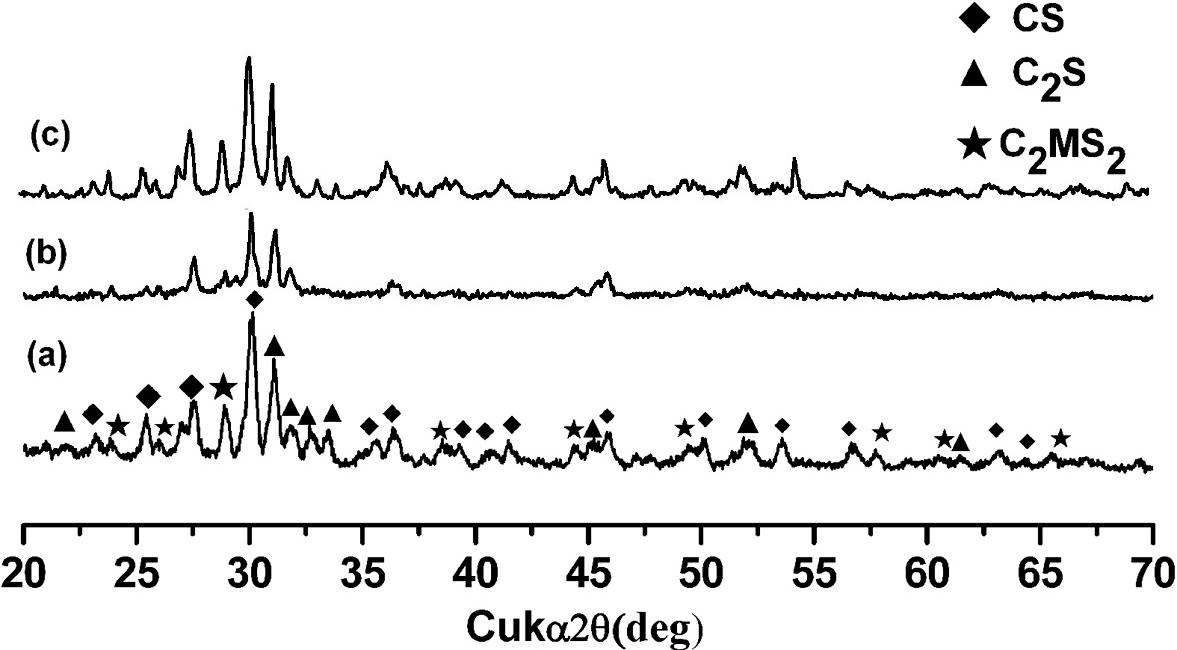

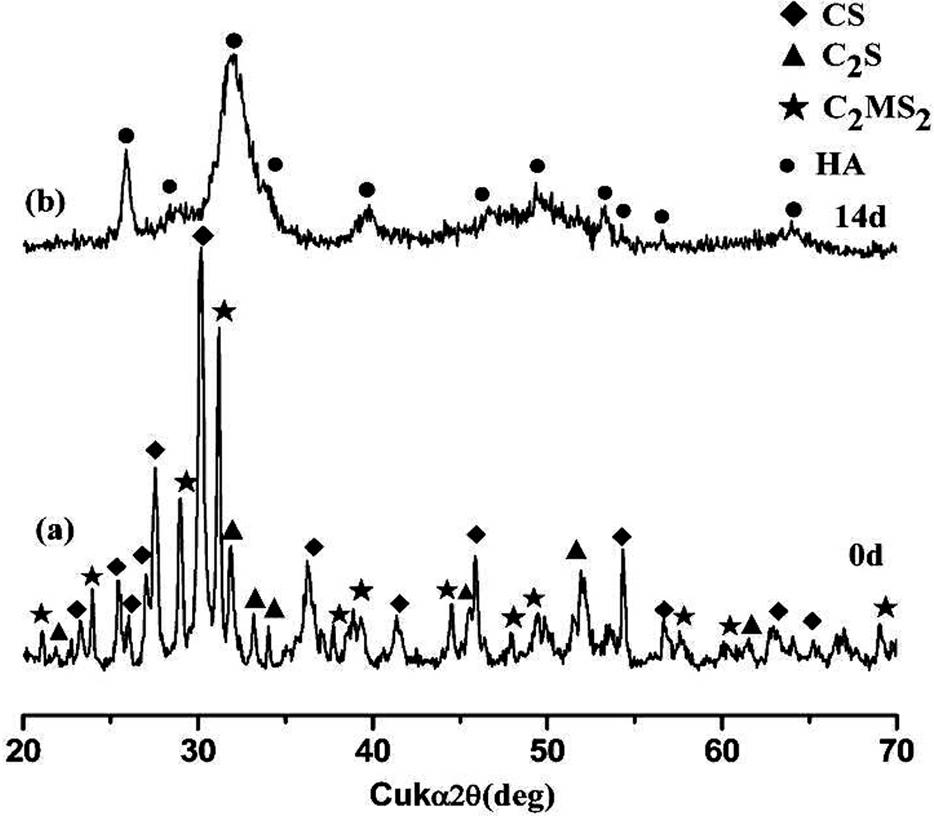

[0022] Use spray drying and granulation technology to granulate and spheroidize MC2 multiphase ceramic powder in block or granular form (with small aspect ratio) (the main working parameters of the spray dryer are: the inlet air temperature is 250±10 °C; the outlet air temperature is 250±10 °C; 120±10 ℃), and then use methods such as sieving to obtain spherical powder suitable for spraying, which greatly improves the fluidity of the ceramic powder, and the powder morphology before and after spraying is as attached figure 1 shown. Using the spraying proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com