Method for preparing sodium sulphite with tail gas from thionyl chloride synthesis process

A technology of thionyl chloride and sodium sulfite, applied in the field of sodium sulfite production, can solve the problems of reduced solubility, low economic value, low purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

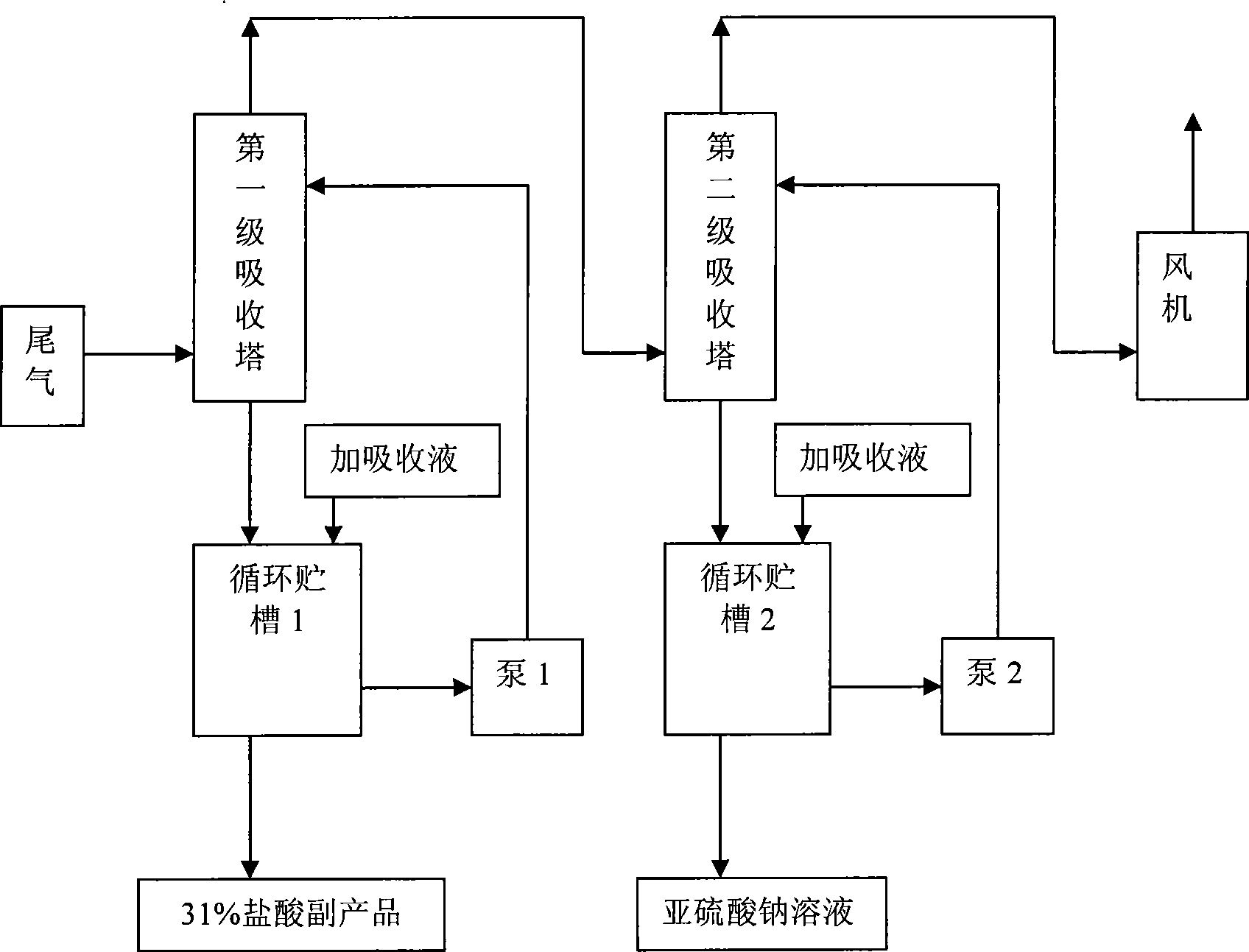

[0073] The tail gas separated from the filling, storage tank, rectification tower top separator, etc. during the synthesis and rectification of thionyl chloride, the gas contained in the tail gas is about 45-55% of sulfur dioxide and about 45% of thionyl chloride 35-45%. Absorb through the first absorption tower first. In the first absorption tower, the temperature of the absorption liquid is set at 10-20°C. The absorption liquid in the absorption tower is clear water. In this absorption tower, the chlorination in the tail gas The thionoxide begins to be decomposed into hydrogen chloride and sulfur dioxide, and the hydrogen chloride gas is cooled and absorbed by water simultaneously. In the gas after the first-stage absorption tower, the removal rate of hydrogen chloride is respectively 98%, and about 31% of commercial hydrochloric acid is obtained; The gas discharged from the first-stage absorption tower passes through the absorption liquid of the second-stage absorption towe...

Embodiment 2

[0075] The tail gas separated from the filling, storage tank, rectification tower top separator, etc. during the synthesis and rectification of thionyl chloride, the gas contained in the tail gas is about 45-55% of sulfur dioxide and about 45% of thionyl chloride 35-45%. It is first absorbed through the first-stage absorption tower. In the first-stage absorption tower, the temperature of the absorption liquid is set at 30-40°C. The absorption liquid in the absorption tower is dilute hydrochloric acid solution. In this absorption tower, the exhaust gas The thionyl chloride begins to decompose into hydrogen chloride and sulfur dioxide, and the hydrogen chloride gas is cooled and absorbed by water at the same time. In the gas after the first-stage absorption tower, the removal rate of hydrogen chloride is 92% respectively, and about 31% of the product is obtained. hydrochloric acid. The gas discharged from the first-stage absorption tower passes through the absorption liquid of ...

Embodiment 3

[0077]The tail gas separated from the filling, storage tank, rectification tower top separator, etc. during the synthesis and rectification of thionyl chloride, the gas contained in the tail gas is about 45-55% of sulfur dioxide and about 45% of thionyl chloride 35-45%. It is first absorbed through the first-stage absorption tower. In the first-stage absorption tower, the temperature of the absorption liquid is set at 50-60°C. The absorption liquid in the absorption tower is dilute hydrochloric acid solution. In this absorption tower, the exhaust gas The thionyl chloride begins to decompose into hydrogen chloride and sulfur dioxide, and the hydrogen chloride gas is cooled and absorbed by water at the same time. In the gas after the first-stage absorption tower, the removal rate of hydrogen chloride is 85% respectively, and about 31% of the product is obtained. Hydrochloric acid; the gas discharged from the first-stage absorption tower passes through the absorption liquid of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com