Groove Gamma gate transistor with high electron mobility and preparing method thereof

A high electron mobility, transistor technology, applied in the field of microelectronics, can solve the problems of weakening the input and output isolation of the device, reducing the yield of the device, and reducing the stability of the device, so as to reduce the gate leakage current and improve the breakdown voltage. , the effect of large drain-source voltage

Inactive Publication Date: 2010-08-11

XIDIAN UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the manufacturing process of the high electron mobility transistor using the stacked field plate structure is relatively complicated. Each additional layer of field plate requires additional process steps such as photolithography, metal deposition, insulating dielectric material deposition, stripping, and cleaning. To make the insulating dielectric material deposited under the field plates of each layer have an appropriate thickness, cumbersome process debugging must be carried out, thus greatly increasing the difficulty of device manufacturing and reducing the yield of devices

Another issue worthy of people's attention is that all high electron mobility transistors using a gate field plate structure will generate additional capacitance between the gate field plate and the two-dimensional electron gas channel, and this additional capacitance will be superimposed into the gate and the gate of the device. In the feedback capacitance between the drains, the feedback capacitance of the device increases, resulting in a certain attenuation of the power characteristics and frequency characteristics of the device.

In addition, the increase of the feedback capacitance of the device will weaken the isolation between the input and output of the device and reduce the stability of the device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

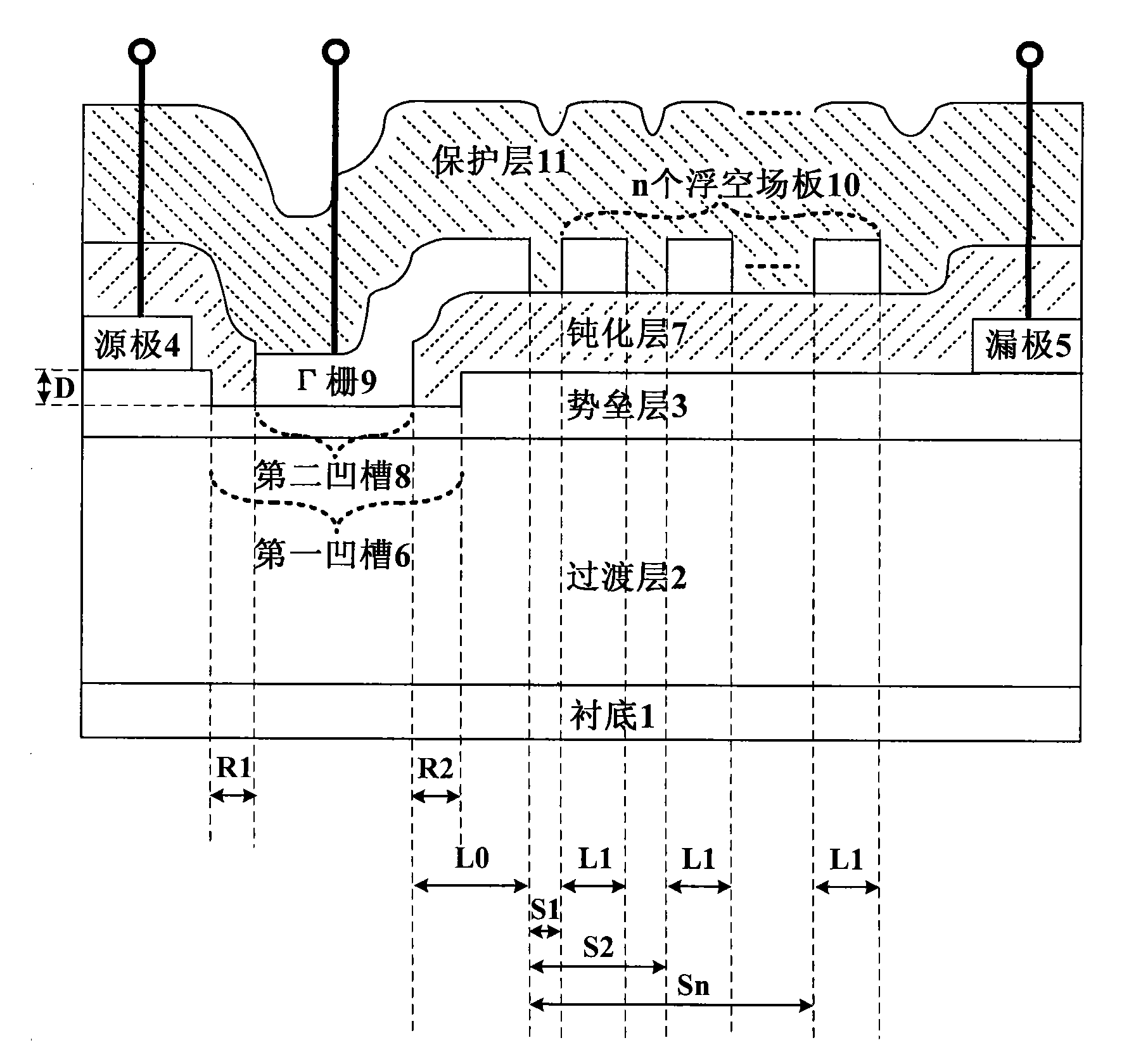

Login to View More Abstract

The invention discloses a groove gamma gate transistor with high electron mobility and a fabrication method thereof. The transistor comprises, from bottom to top, a substrate (1), a transition layer (2), a barrier layer (3), a source electrode (4), a drain electrode (5), a passivation layer (7), a gamma gate (9) and a protection layer (11); a first groove (6) is opened on the barrier layer (3), asecond groove (8) is opened on the passivation layer (7), wherein, n floating field plates (10) are deposited on the passivation layer (7) (n is not less than 1), and the floating field plates and the gamma-gate form a composite gate field plate structure. All the floating field plates have the same size and are mutually independent, and the distance between two adjacent floating field plates increases based on the number of the floating field plates arranged along the direction from the gamma gate to the drain electrode. The n floating field plates are in a floating state and are completed together with the gamma gate by one-time process. The groove gamma gate transistor has the advantages of high yield, good frequency characteristic and high output power, and the groove gamma gate transistor and the fabrication method can be used for fabricating high-frequency high power devices based on III-V group compound semiconductor heterojunction structure.

Description

technical field The invention belongs to the technical field of microelectronics, and relates to semiconductor devices, in particular to a grooved Γ-gate high electron mobility transistor based on the heterojunction structure of III-V compound semiconductor materials, which can be used as a microwave, millimeter wave communication system and radar system. basic device. technical background As is well known in the industry, semiconductor materials composed of group III elements and group V elements, that is, group III-V compound semiconductor materials, such as gallium nitride (GaN)-based, gallium arsenide (GaAs)-based, indium phosphide (InP)-based And other semiconductor materials, their bandgap widths are often quite different, so people usually use these III-V compound semiconductor materials to form various heterojunction structures. Due to the large difference in the band gap of III-V compound semiconductor materials on both sides of the heterojunction interface in the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L29/778H01L29/06H01L21/335

Inventor 郝跃毛维过润秋杨翠

Owner XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com