Carbon nanotube and metal nano-particle complexes and synthetic method thereof

A technology of metal nanoparticles and carbon nanotubes, which is applied in the field of carbon nanotubes, can solve the problems of reducing the catalytic performance of carbon nanotubes and metal nanoparticle composites, uneven metal particle size, and reducing the utilization rate of metal particles, achieving excellent Catalytic effect, uniform distribution, and excellent electrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 21 mg of potassium chloroplatinate to 5 ml of water, then add 10 ml of polyol, 0.1 to 1.5 g of ionic liquid, and 20 mg of carbon nanotubes, and heat to reflux temperature under vigorous stirring for 1 to 10 hours. Then the obtained mixture is subjected to centrifugation, and the obtained precipitate is washed several times, centrifuged and then naturally air-dried to obtain the final product.

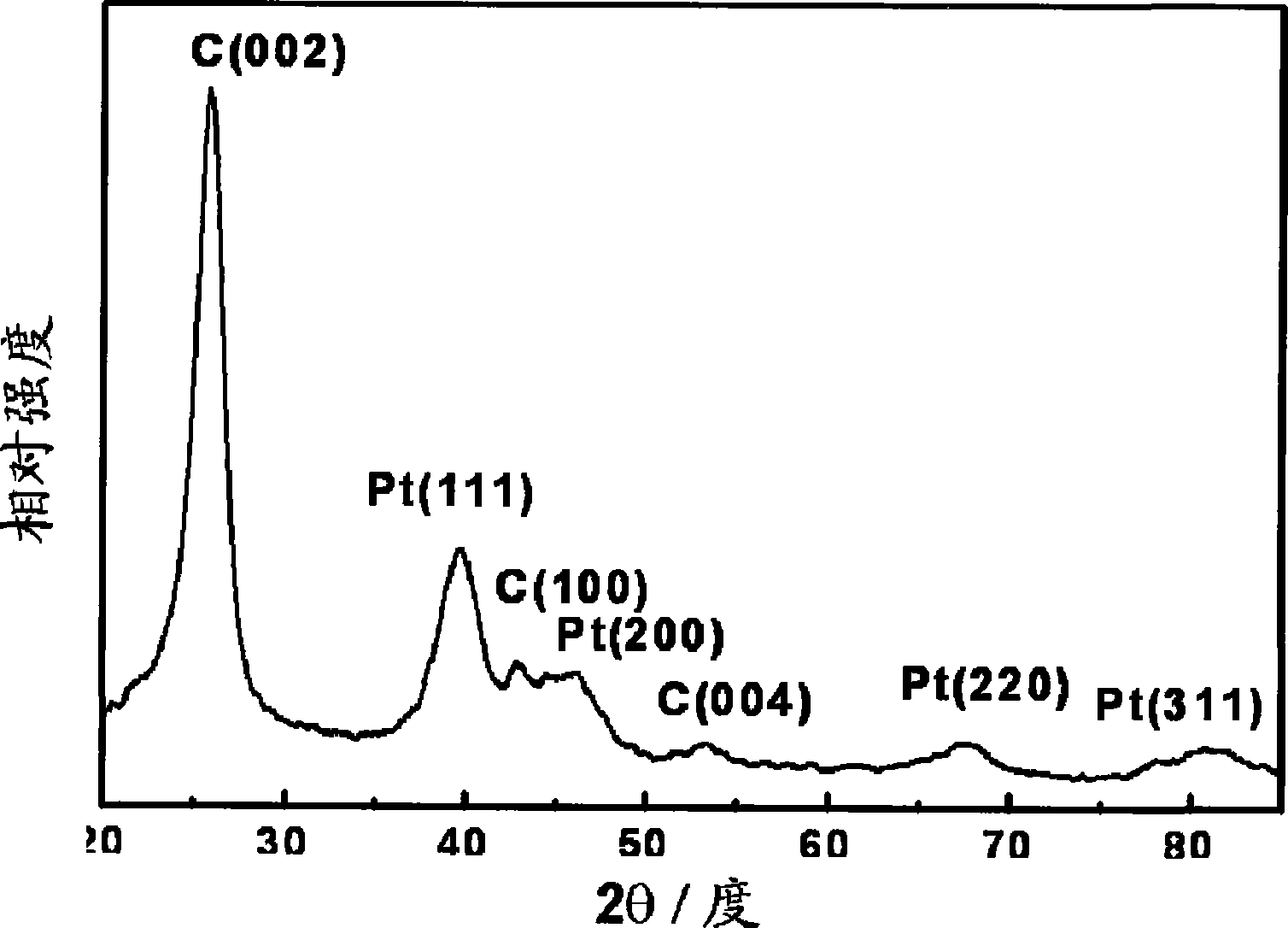

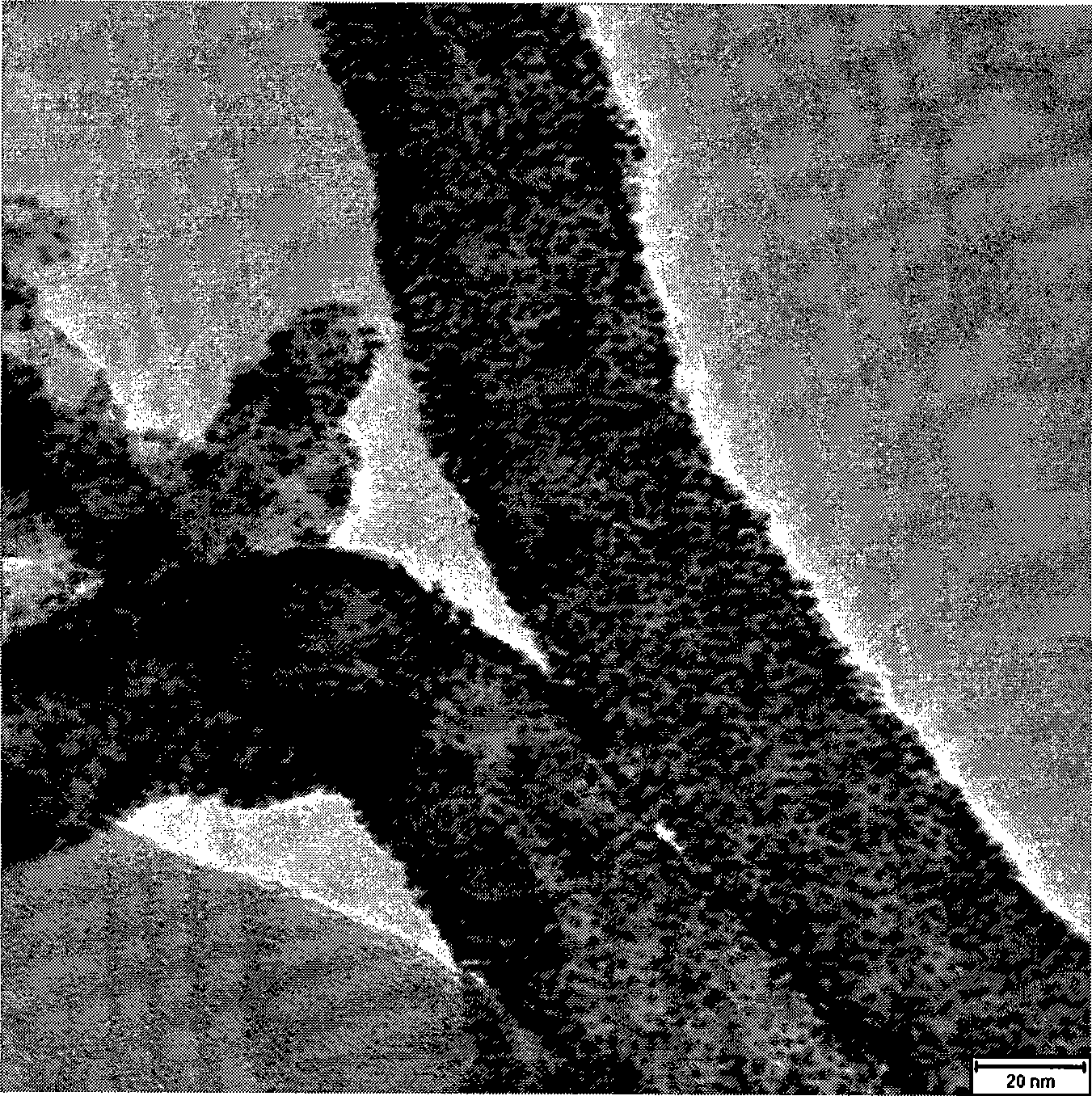

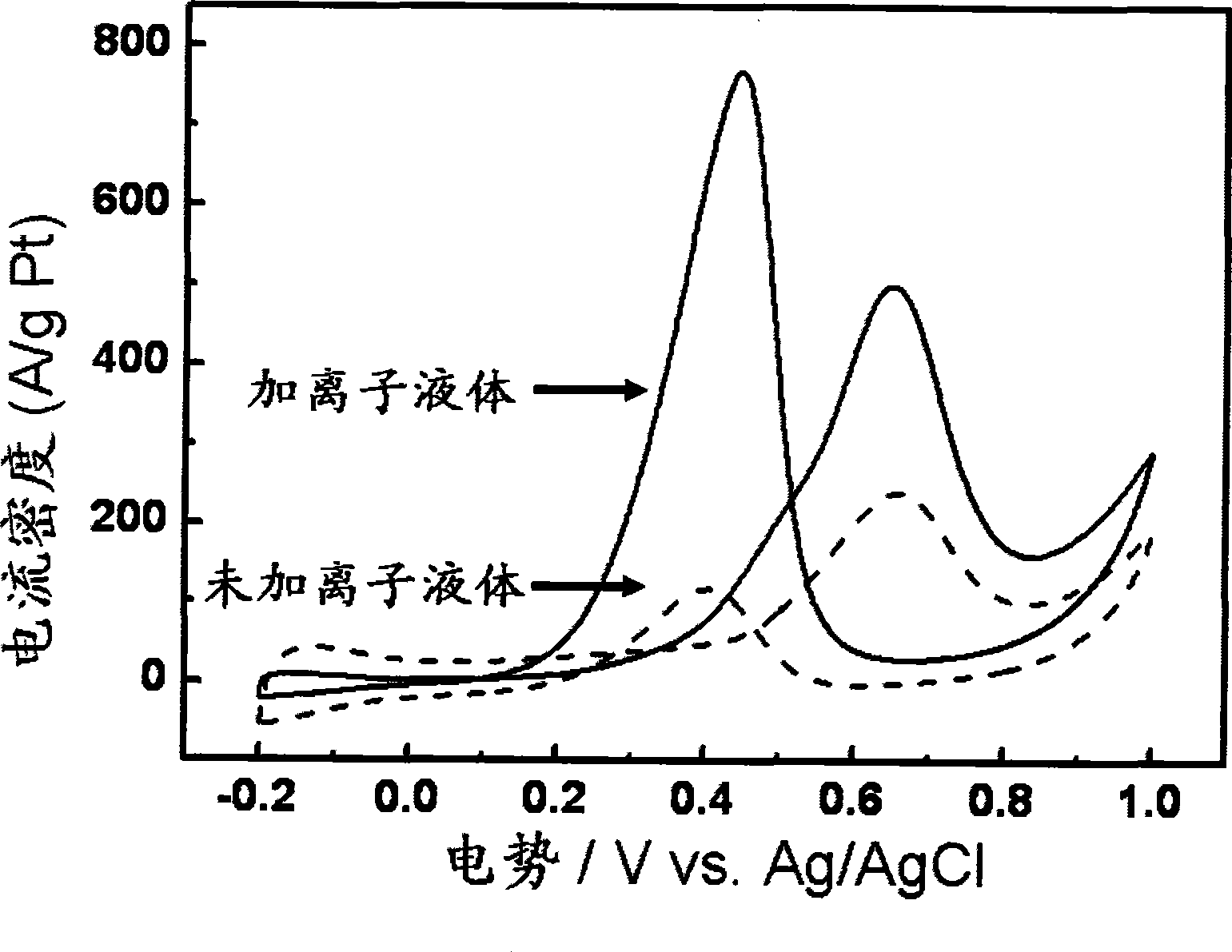

[0032] Such as figure 1 Shown is the X-ray powder diffraction pattern of the composite of carbon nanotubes and platinum nanoparticles synthesized by the method described above. C in the figure represents the diffraction peak of carbon nanotubes, and Pt represents the diffraction peak of platinum nanoparticles, so the product is composed of carbon nanotubes and platinum. Such as figure 2 Shown is the high resolution electron micrograph of the above product. It can be seen from the figure that the platinum nanoparticles are evenly distributed on the surface of the carbon na...

Embodiment 2

[0035]Add 21 mg of potassium chloroplatinate and 9 mg of ruthenium chloride to 5 ml of water, then add 10 ml of polyol, 0.1 to 1.5 g of ionic liquid, and 20 mg of carbon nanotubes, and heat to reflux temperature for 1 hour under vigorous stirring to 10 hours. Then the obtained mixture is subjected to centrifugation, and the obtained precipitate is washed several times, centrifuged and then naturally air-dried to obtain the carbon nanotube and platinum-ruthenium alloy nanoparticle composite.

[0036] Such as Figure 4 Shown is a high-resolution electron microscope image of the composite of the above-mentioned carbon nanotubes and platinum-ruthenium alloy nanoparticles. It can be seen from the figure that the platinum-ruthenium alloy nanoparticles are evenly distributed on the surface of the carbon nanotubes, and no free platinum-ruthenium alloy nanoparticles are observed, and almost all the platinum-ruthenium alloy nanoparticles are selectively loaded on the carbon nanotubes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com