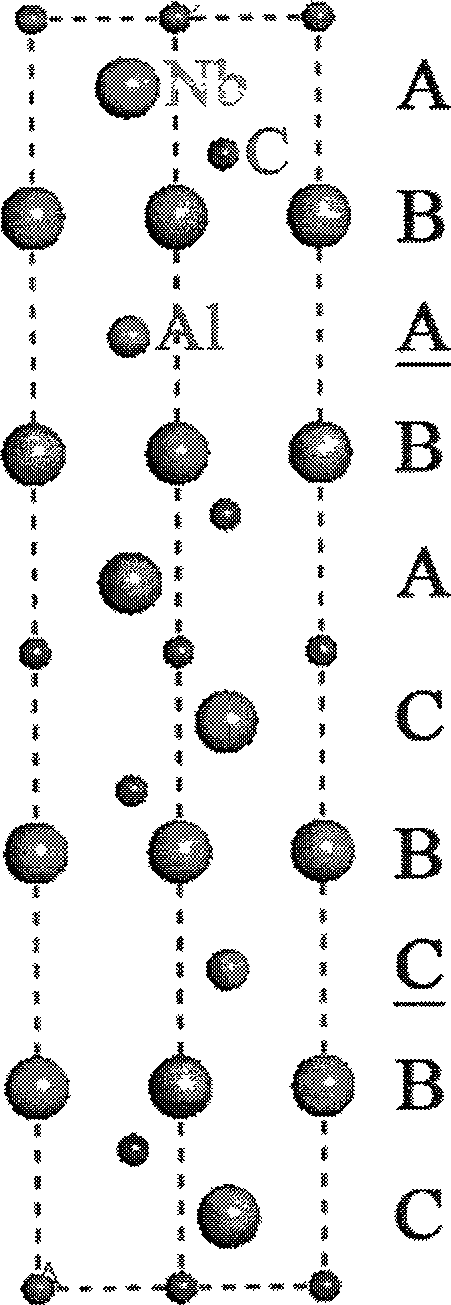

Nb4AlC3 block ceramic synthesized by hot pressing at in-situ reaction and preparation method thereof

An in-situ reaction and block technology, applied in the field of single-phase bulk ceramics and preparation, can solve the problems of complex and impractical dense block process, and achieve the effects of good damage tolerance, low cost and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

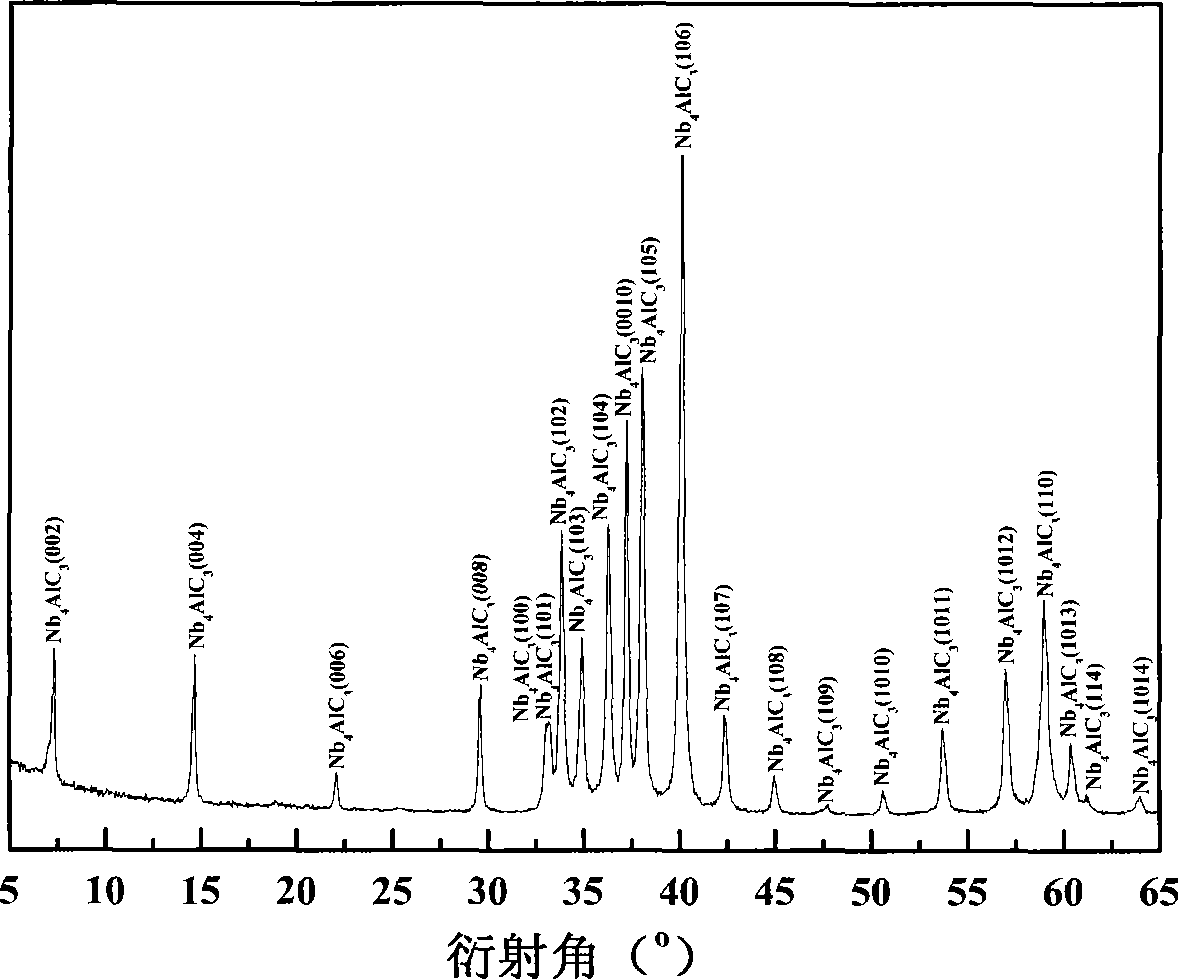

Embodiment 1

[0022] With 24.78 grams of niobium powder, 1.98 grams of aluminum powder, and 2.16 grams of graphite powder as raw materials (the molar ratio is 4:1.1:2.7, and the particle size of the raw material powder is 200 mesh), ball milling in a resin tank under dry conditions for 12 hours, after sieving Put it into a graphite mold for cold pressing (10MPa), sinter in a hot-press furnace with argon gas, the heating rate is 15°C / min, sinter at 1650°C, the holding time is 60 minutes, and the applied pressure is 25MPa. The density measured by the Archimedes method is 6.97g / cm 3 , 99% of the theoretical density. According to X-ray diffraction analysis, it is basically all Nb 4 AlC 3 . Determination of Nb 4 AlC 3 The Vickers hardness of the bulk ceramic is 2.6GPa, the compressive strength is 515MPa, and the shear strength is 116MPa.

Embodiment 2

[0024] The difference from Example 1 lies in that the molar ratio of raw material powder is different, and the sintering temperature, holding time and applied pressure are different.

[0025] Using 24.78 grams of niobium powder, 2.16 grams of aluminum powder, and 2.24 grams of graphite powder as raw materials (the molar ratio is 4:1.2:2.8), they were ball milled in a resin tank for 24 hours under dry conditions, and then sieved and put into a graphite mold for cold pressing. (10MPa), sintered in a hot-press furnace with argon gas, the heating rate is 15°C / min, sintered at 1700°C, the holding time is 120 minutes, and the applied pressure is 30MPa. The density measured by the Archimedes method is 6.98g / cm 3 , 99% of the theoretical density. According to X-ray diffraction analysis, it is basically all Nb 4 AlC 3 . Determination of Nb 4 AlC 3 The bulk ceramics have an elastic modulus of 306GPa and a shear modulus of 127GPa.

Embodiment 3

[0027] The difference from Example 1 is that the molar ratio of raw material powder is different, and the sintering temperature, heating rate, holding time and applied pressure are all different.

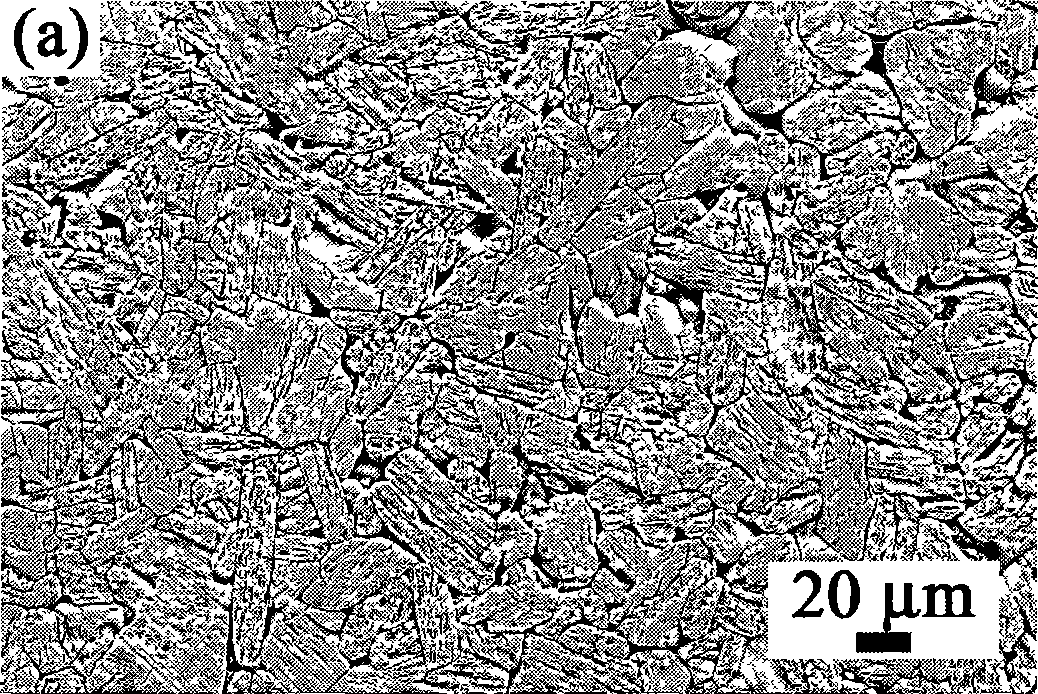

[0028] With 24.78 grams of niobium powder, 2.34 grams of aluminum powder, and 2.32 grams of graphite powder as raw materials (the molar ratio is 4:1.3:2.9, and the particle size of the raw material powder is 200 mesh), ball milling in a resin tank under dry conditions for 20 hours, after sieving Put it into a graphite mold for cold press molding (20MPa), sinter in a hot-press furnace with argon gas, the heating rate is 10°C / min, sinter at 1600°C, the holding time is 120 minutes, and the applied pressure is 20MPa. The density measured by the Archimedes method is 6.94g / cm 3 , 98% of the theoretical density. According to X-ray diffraction analysis, it is basically all Nb 4 AlC 3 . Determination of Nb 4 AlC 3 The bending strength of the bulk ceramic is 346MPa, and the fracture tou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com