Water dispersive polyisocyanate curing agent and preparation method thereof

A polyisocyanate and curing agent technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of small grafting amount, limited improvement of anti-corrosion performance, and influence on the popularization and application of water-based anti-corrosion coatings , to achieve the effect of improving the anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0022] Examples 1 to 4 Preparation of water-dispersed polyisocyanate curing agent

[0023] (1) The formula is shown in Table 1 (the dosages are all parts by weight)

[0024] Table 1

[0025] Component

raw material name

Dosage

Example 1 Dosage

Example 2 Dosage

Example 3 Dosage

Example 4 Polyisocyanate

N75, solid content 70% by weight

N3390, solid content 90% by weight 142.86

/ 142.86

/ /

111.11 /

111.11 Hydroxy cyclic ether compound

α-Hydroxycyclobutyl ether

α-hydroxy, β-methyl cyclobutyl ether 5.0

/ 15.0

/ /

5.0 /

15.0 Cosolvent N-methylpyrrolidone 11.67 5.0 11.67 5.0

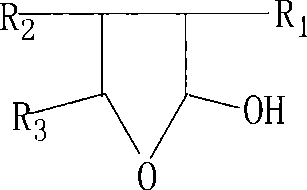

[0026] in FIG. 1:

[0027] N75 is the product brand of 1,6-hexamethylene diisocyanate dimer produced by Bayer;

[0028] N3390 is the product brand of 1,6-hexamethylene diisocyanate trimer produced by Bayer;

[0029] α-Hydroxycyclobutyl ether and α-hydroxyl, β-methylcyclobutyl ether are all commercially available products;

...

Embodiment 5

[0033] Example 5 Preparation of water-based two-component anti-corrosion coating A

[0034] (1) Preparation of slurry

[0035] Take 24 parts by weight of iron red; 15 parts by weight of zinc phosphate; 15 parts by weight of mica powder; 16 parts by weight of kaolin; 30 parts by weight of deionized water; and 0.7 parts by weight of water-soluble dispersant 270. Mix the above components uniformly, grind them to a fineness below 50 microns with a sand mill, and store them for later use;

[0036] (2) Preparation of paint

[0037] Component A: curing agent product A prepared in Example 1;

[0038] Component B: Mix the above slurry with hydroxy acrylate emulsion VPLS2227 / 1 at a weight ratio of 100:82, then add thickener Tego3000 (the addition is 0.6% of the total weight of the coating) and defoamer Tego902W ( The added amount is 0.2% of the total weight of the coating), and the mixture is evenly stirred to form the second component;

[0039] Before construction, mix component A and comp...

Embodiment 6

[0040] Example 6 Preparation of water-based two-component anti-corrosion coating B

[0041] (1) The preparation of the slurry is the same as in Example 5;

[0042] (2) Preparation of paint

[0043] Component A: curing agent product B prepared in Example 2;

[0044] Component B: Mix the above slurry with hydroxy acrylate emulsion VPLS2227 / 1 at a weight ratio of 100:70, then add thickener Tego3000 (the addition is 0.6% of the total weight of the coating) and defoamer Tego902W ( The added amount is 0.2% of the total weight of the coating), and the mixture is evenly stirred to form the second component;

[0045] Before construction, mix component A and component B at a weight ratio of 1:6.9, and stir evenly to obtain a water-based two-component anticorrosive coating B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com