Method for producing galacto-mannan-oligosaccharides by enzymatic degradation of sophora bean gum

A technology of galactomannan oligosaccharides and enzymatic degradation, applied in the field of enzymatic degradation of locust bean gum to produce galactomannan oligosaccharides, can solve problems such as the method of producing galactomannan oligosaccharides from locust bean gum that has not been seen, and achieve the product The effect of good structural stability, low cost and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

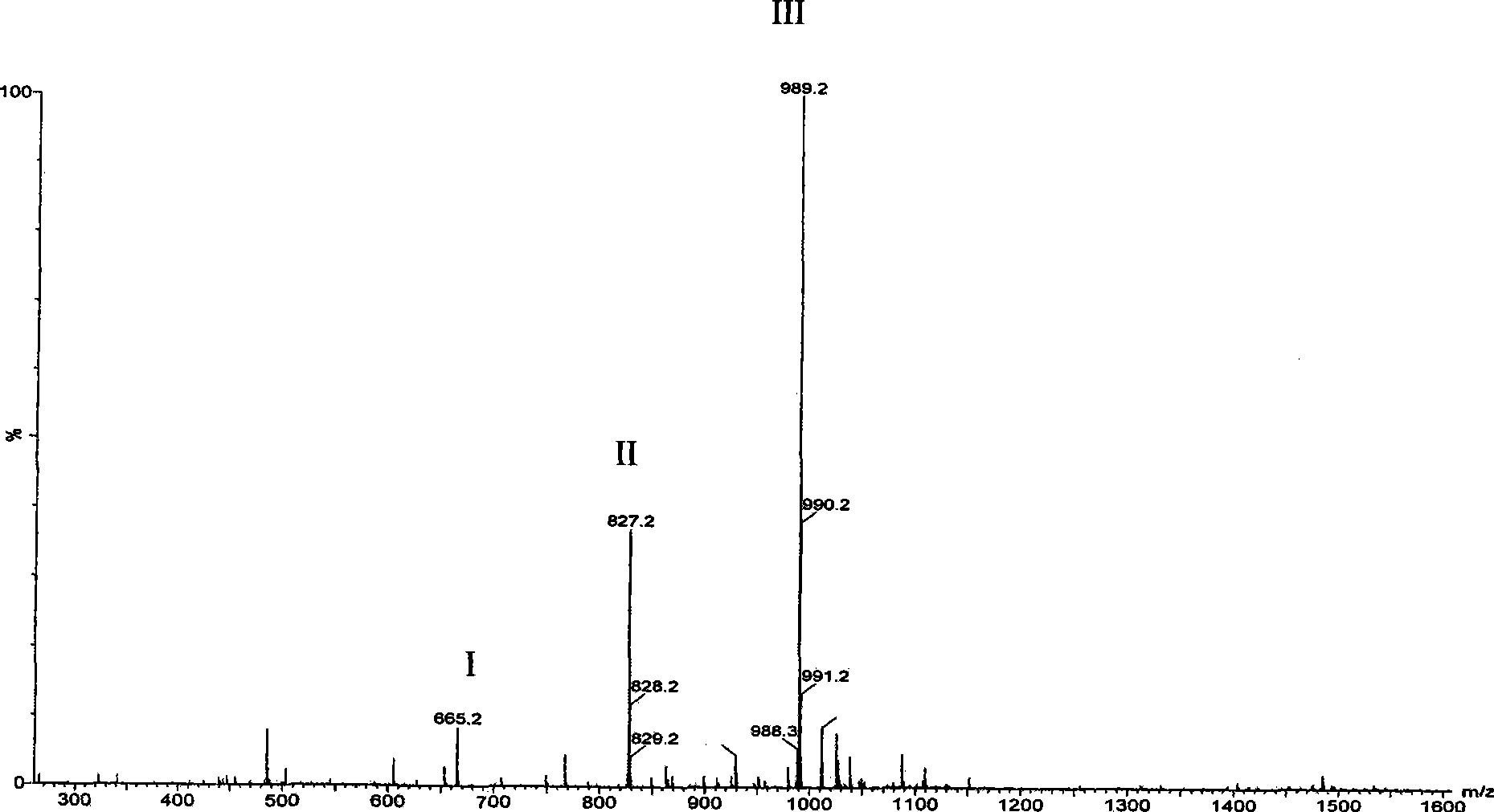

Image

Examples

Embodiment Construction

[0010] The bacterial species alkalophilic bacillus used in the present invention can be cultivated on common bacterial culture mediums such as nutrient broth or beef extract peptone medium, and after liquid shaking culture for 18-24 hours, the growth reaches the logarithmic phase, and the culture solution at this time can be used as Fermented seeds are used for inoculation of enzyme-producing medium. Prepare the enzyme-producing medium according to the following components: 4 g of guar gum, 20 g of soybean powder, (NH 4 ) 2 HPO 4 5g,NH 4 Cl 1g, K 2 HPO 4 ·3H 2 O 1g, MgSO 4 ·7H 2 O 0.5g, NaCl 0.5g, CaCl 2 0.1g, FeSO 4 ·7H 2 O 0.001g, finally add water to a total weight of 1kg, adjust the pH of the enzyme culture medium to 8.0 with 1M NaOH or HCl aqueous solution. After the enzyme-producing medium was sterilized by high-pressure steam at 121°C for 20 minutes, it was cooled to room temperature, and an alkalophilic bacillus culture solution in the logarithmic phase wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com