Method for preparing AlxIn1-xN film

A technology of alxin1-xn and thin film, which is applied in the field of preparation of nitride photoelectric thin film materials, can solve problems such as poor preferred orientation, and achieve the effects of good preferred orientation, stable deposition rate, and low sheet resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

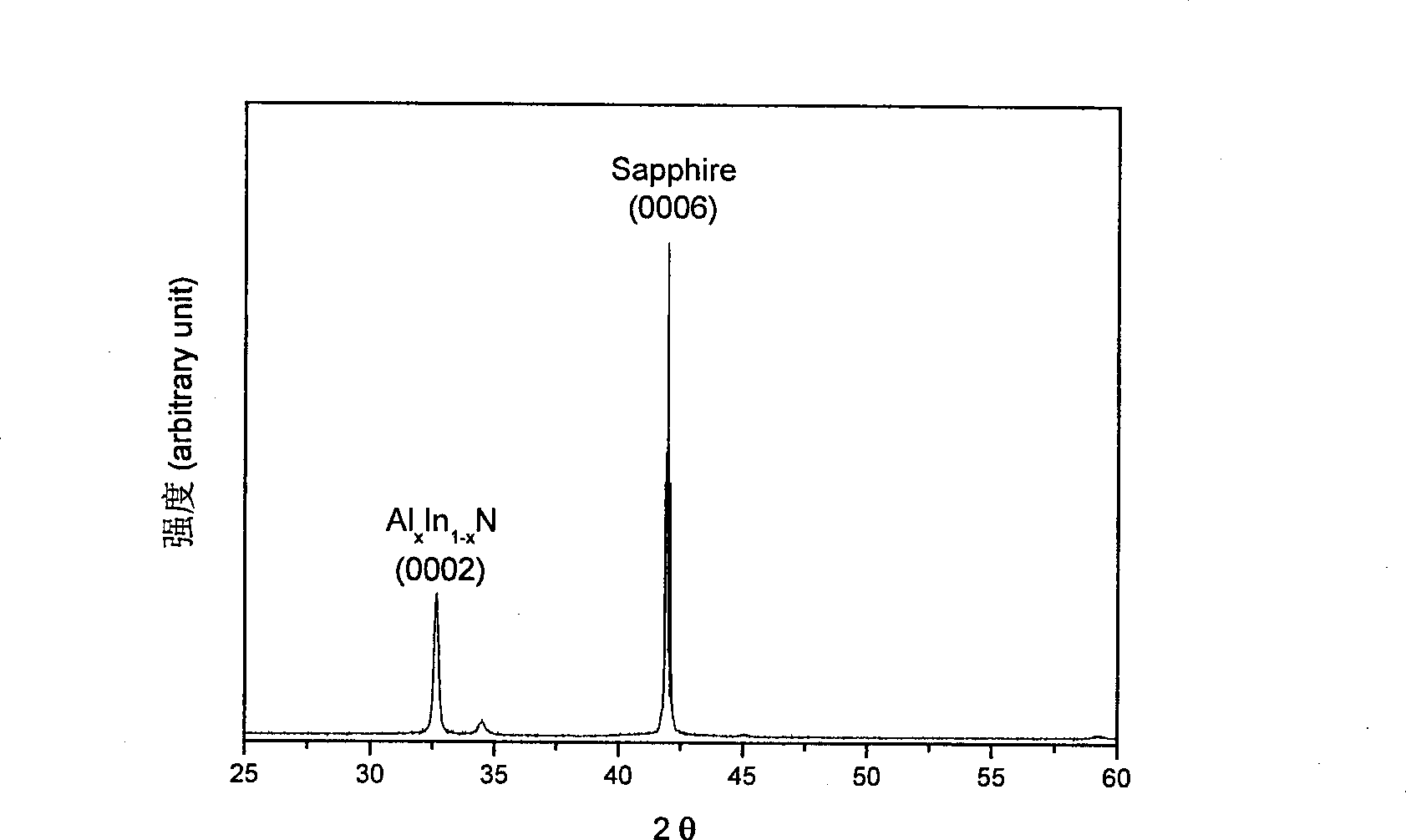

Embodiment 1

[0030] In this example, Al x In 1-x The preparation method of the N thin film operates according to the following process steps in sequence:

[0031] (1) Substrate processing

[0032] Using sapphire as the substrate, the sapphire substrate was ultrasonically cleaned in acetone for 30 minutes at room temperature and pressure, and then heated in H 2 SO 4 -H 3 PO 4 Solution (H2 SO 4 with H 3 PO 4 The volume ratio is 3:1) and boiled for 15 minutes, and then washed with deionized water for 10 minutes. After the substrate is cleaned, it is placed in a closed box and blown dry with nitrogen;

[0033] (2) Growth of buffer layer AlN

[0034] The growth of the buffer layer AlN was completed in an ultra-high vacuum multifunctional magnetron sputtering equipment (model: JGP560, manufacturer: Shenyang Scientific Instrument Development Center Co., Ltd., Chinese Academy of Sciences) with a background vacuum of 4.5×10 -5 Pa; the sapphire substrate processed through step (1) is put ...

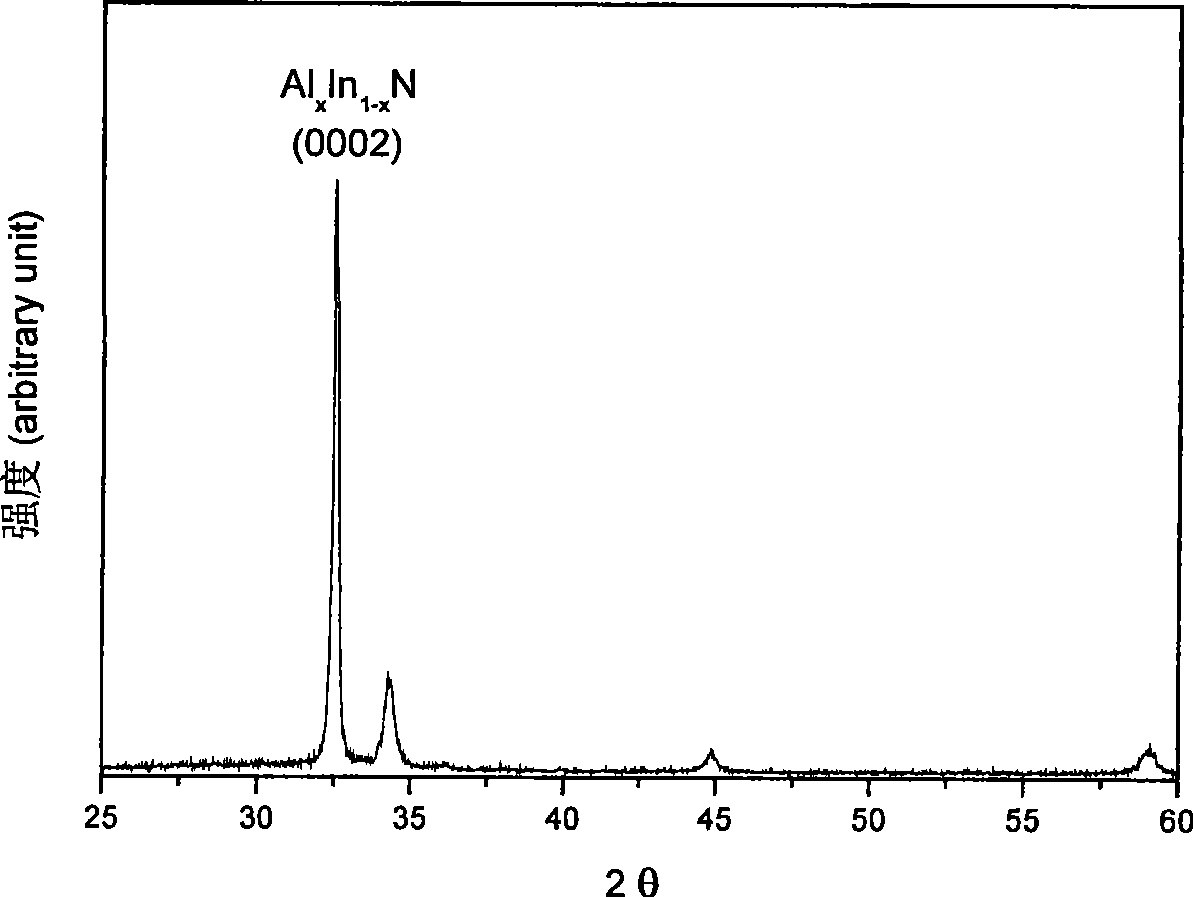

Embodiment 2

[0040] In this example, Al x In 1-x The preparation method of the N thin film operates according to the following process steps in sequence:

[0041] (1) Substrate processing

[0042] Taking Si(111) as the substrate, at room temperature and pressure, the Si(111) substrate was first ultrasonically cleaned in trichlorethylene for 20 minutes, ultrasonically cleaned in acetone solution for 30 minutes, and then soaked in HF for 10 minutes , and then rinsed with deionized water for 10 minutes. After the substrate is cleaned, it is placed in a closed box and blown dry with nitrogen;

[0043] (2) Growth of buffer layer AlN

[0044] The growth of the buffer layer AlN is completed in an ultra-high vacuum multifunctional magnetron sputtering device (same as Example 1), and the background vacuum is 4.5 × 10 -5 Pa; the Si (111) substrate processed through step (1) is put into a sputtering chamber, and a buffer layer AlN is grown on the substrate by sputtering under vacuum conditions; ...

Embodiment 3

[0050] In this example, Al x In 1-x The preparation method of the N thin film operates according to the following process steps in sequence:

[0051] (1) Substrate processing

[0052] Using glass as a substrate, the glass substrate was firstly ultrasonically cleaned in acetone for 30 minutes, ultrasonically cleaned in absolute ethanol for 20 minutes, and then deionized water for 10 minutes at room temperature and pressure. After the substrate is cleaned, it is placed in a closed box and blown dry with nitrogen;

[0053] (2) Growth of buffer layer AlN

[0054] The growth of the buffer layer AlN is completed in an ultra-high vacuum multifunctional magnetron sputtering device (same as Example 1), and the background vacuum is 4.5 × 10 -5 Pa; put the glass substrate processed through step (1) into the sputtering chamber, and use the sputtering method to grow a buffer layer AlN on the substrate under vacuum conditions; the target material is Al (purity 99.8%), and the reaction g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com