Preparation of AlN growth face composite substrate and nitride semiconductor device

A technology of nitride semiconductors and composite substrates, which is applied in semiconductor/solid-state device manufacturing, single crystal growth, crystal growth, etc., can solve the problems of high price, limit the wide application of devices, and high dislocation density, and reduce lattice loss. matching, good optical and electrical properties, and small lattice mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

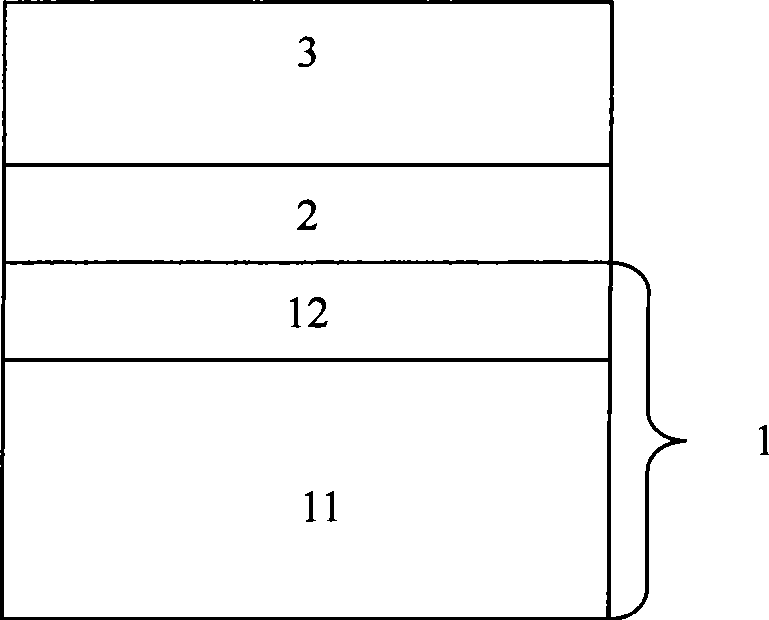

[0017] like figure 1 As shown, a metal-organic chemical vapor deposition system is used to grow a composite substrate 1 with an AlN growth surface, a transition layer 2 and a nitride semiconductor structural material layer 3, wherein the composite substrate 1 with an AlN growth surface includes a sapphire substrate 11 and An AlN epitaxial layer 12 is grown on the substrate. Trimethylgallium (TMGa), trimethylaluminum (TMA1) and trimethylindium (TMIn) were used as Group III sources during the growth process, and high-purity ammonia (NH 3 ) as the V group source, high-purity hydrogen and nitrogen as the carrier gas, magnesium dicene (CP 2 Mg) and high-purity silane (SiH 4 ) as the doping source. Place the sapphire substrate 11 in the growth system, heat it to 1000-1200° C. with hydrogen gas, and keep the high temperature for 10 minutes to remove the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com