Method for improving washing efficiency for tail gas from wet-process phosphoric acid manufacture

A technology of tail gas washing and wet-process phosphoric acid, which is applied in the direction of separation methods, chemical instruments and methods, phosphorus compounds, etc., can solve the unsolved problems of tail gas washing efficiency, low, fluorine content not meeting emission standards, etc., and achieve favorable Effects of washing efficiency, increasing initial concentration, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

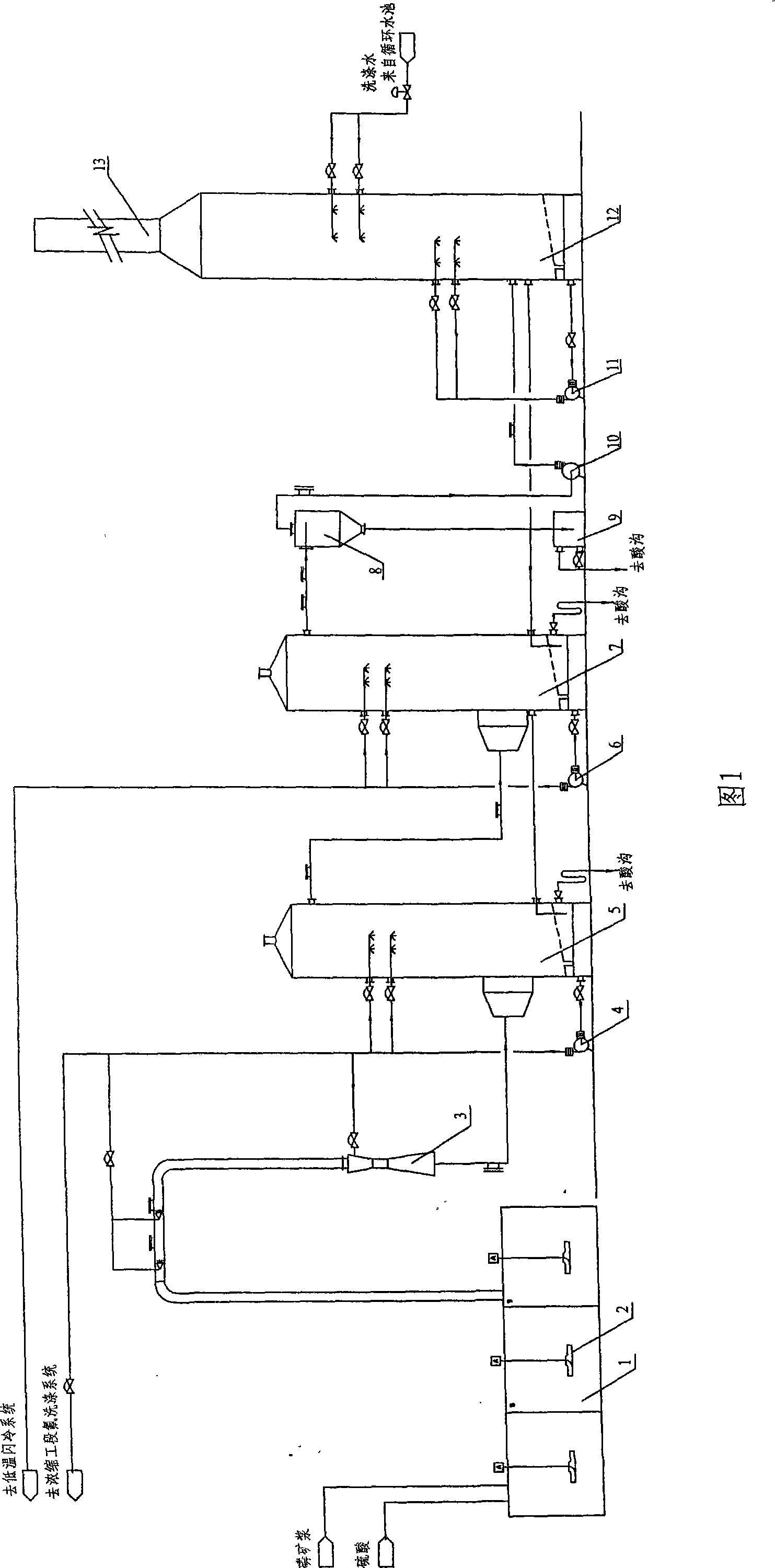

[0011] Example 1 The tail gas scrubbing process of wet process phosphoric acid production as shown in the attached figure.

[0012] The mixing device 2 of the reaction tank 1 is equipped with an oil seal to seal the inspection port cover to completely isolate the inside and outside of the reaction digestion tank; the tail gas from the reaction digestion tank 1 first passes through the first-stage Venturi scrubber 3 and the first scrubber 5 cycle washing, control the concentration of the washing liquid to be less than 1%, remove most of the fluoride in the tail gas, the washing liquid is sent out through the circulating liquid pump 4, and is used by the phosphoric acid concentrated fluorine absorption system; the tail gas after washing enters the second washing tower 7, Under negative pressure, a large amount of water is used for circulating washing, and the washing liquid is sent out through the circulating liquid pump 6, and the washing liquid is returned to the phosphoric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com