Treatment of wastewater from vitamin C production with reinforcement, catalysis and ozonization of physical means

A physical method, a technology for producing wastewater, applied in the directions of oxidized water/sewage treatment, natural water treatment, chemical instruments and methods, etc., can solve the problems of high operating cost, difficult industrial application, low ozone utilization rate, etc., to reduce COD and Effect of hardness, operating cost reduction, oxygen consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

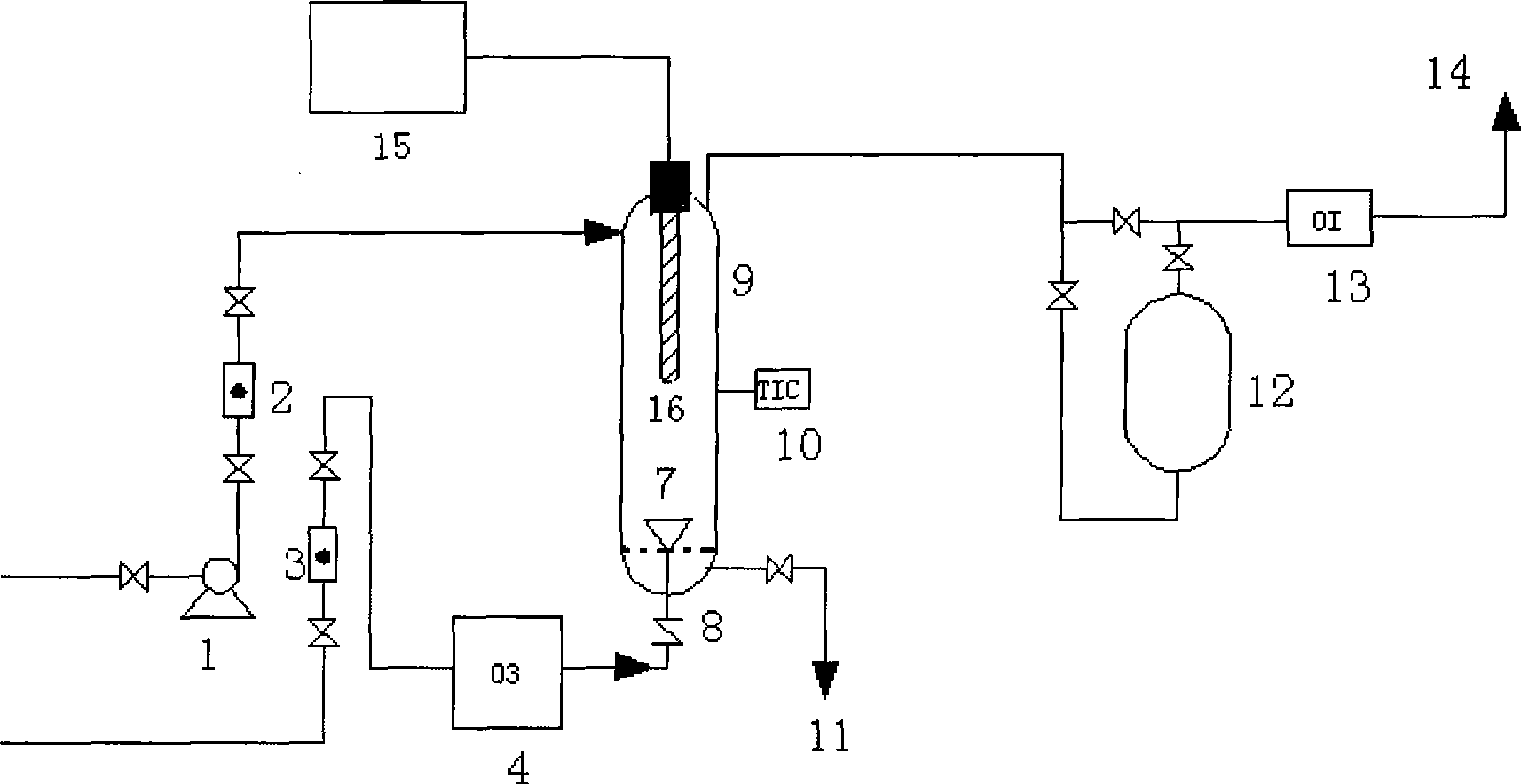

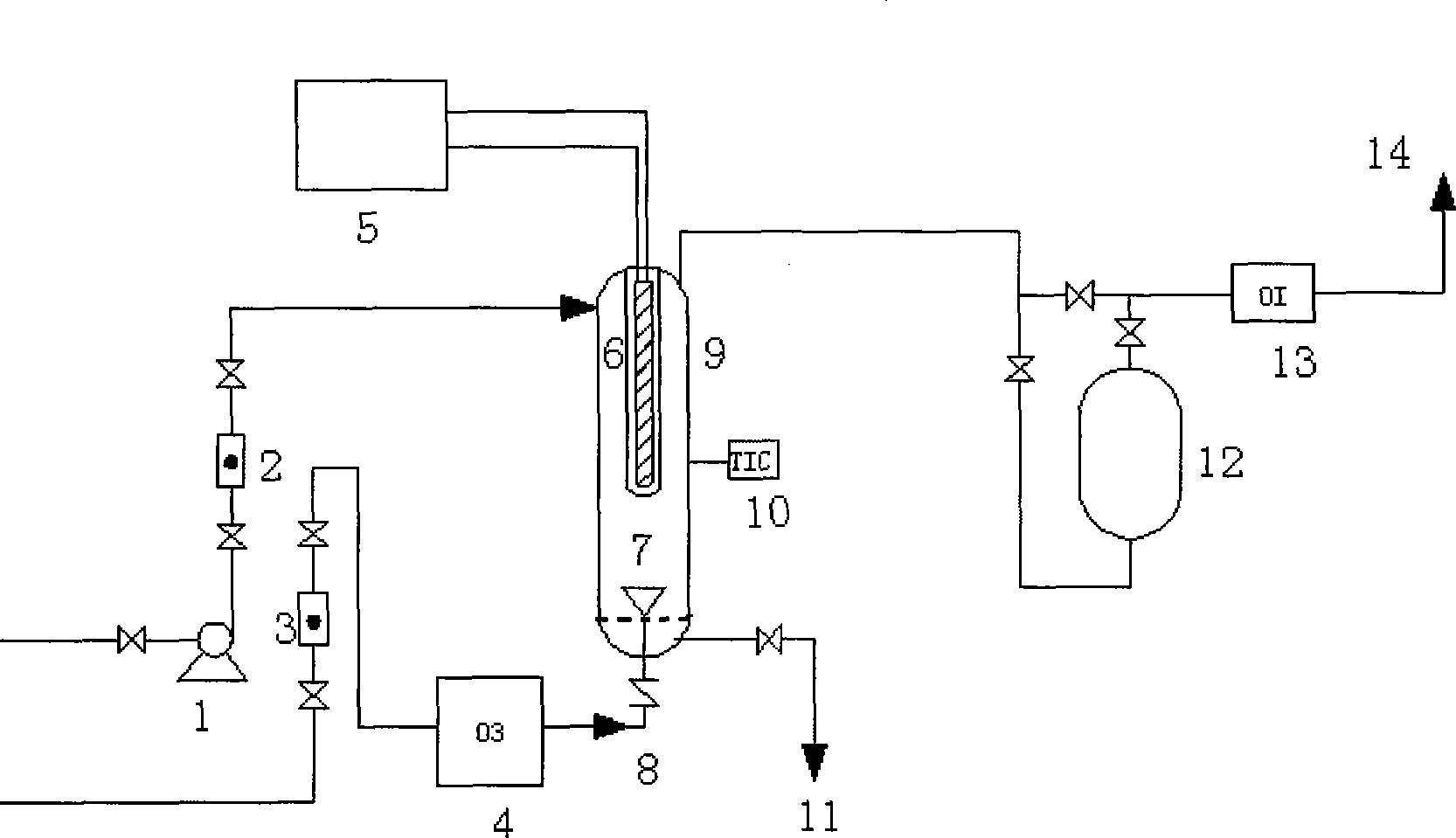

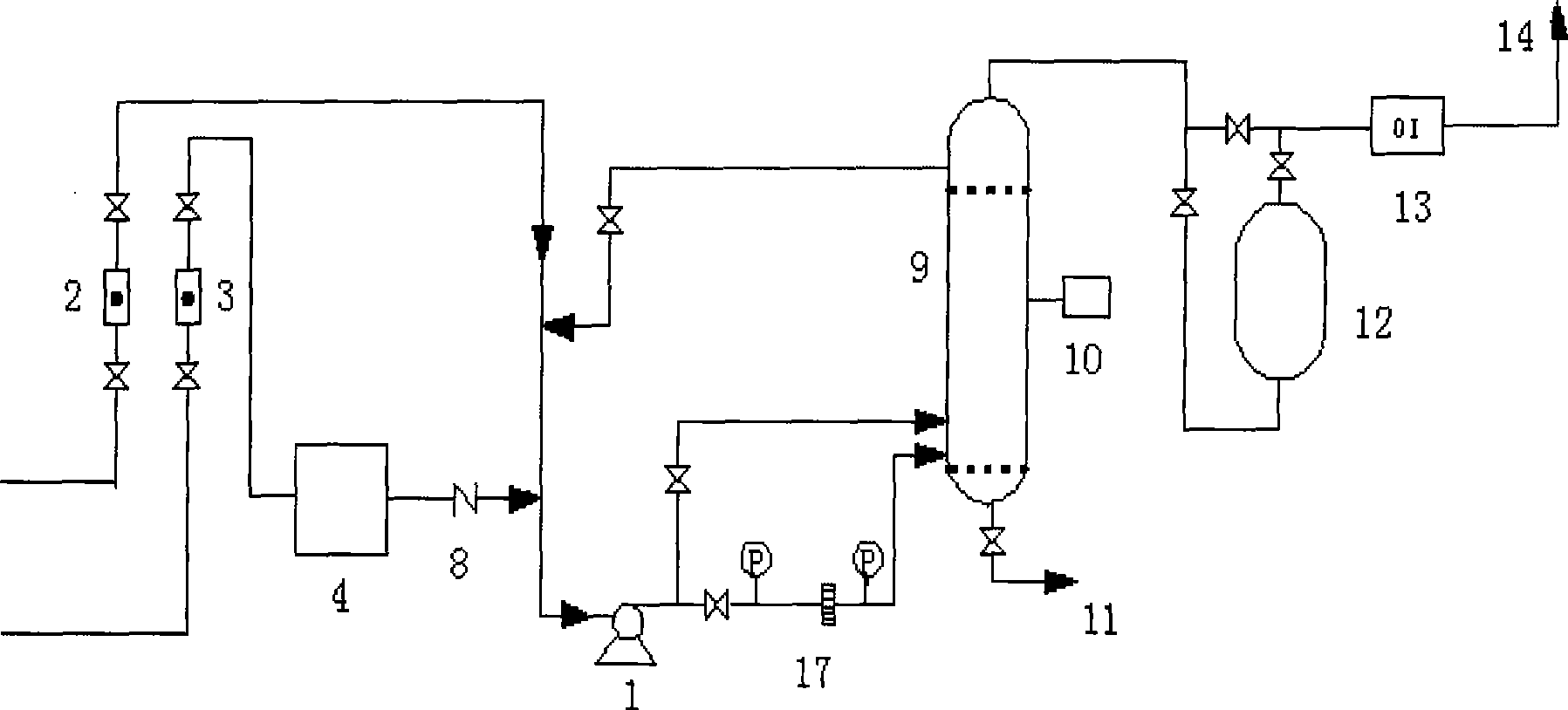

[0031] use figure 2 The shown ultraviolet light enhanced ozonation treatment device has an effective volume of a 2.5L bubble column reactor, and a UV light source 6 with a power of 14W and a wavelength of 290nm is placed in the inner sleeve of the oxidation reactor 9 (irradiation power is equivalent to 5.6 W / L reactor). with TiO 2 (20%)-SiO 2 (80%) The solid particle of the composite is the catalyst, the loading amount of the catalyst is 15g, and the particle size is 80-120 mesh. The reaction temperature was controlled at 75°C.

[0032] VC wastewater is taken from the effluent of the three sedimentation tanks of Jiangsu Jiangshan Pharmaceutical Co., Ltd., COD cr : 289mg / l, chromaticity: 140 times, calcium ion concentration 1080mg / l. The feed rate of VC wastewater is 10 L / h, and the residence time of VC wastewater in the oxidation reactor 9 is 15 minutes.

[0033] Adjust the oxygen flow rate of the oxygen / air flow meter 3 to be 12L / h, and observe through the tail gas ozo...

Embodiment 2

[0035] Change the source of VC wastewater and use wastewater from the VC production workshop, which is reddish brown, with a chroma greater than 450, and COD Cr The value is 11270mg / l, and it has a pungent taste. Ca ion 52mg / L.

[0036] Using the same device and the same catalyst as in Example 1. The reaction temperature was controlled at 75°C. The feeding rate of VC wastewater is 2.5 L / h, and the residence time of VC wastewater in the oxidation reactor 9 is 60 min.

[0037] Adjust the oxygen flow rate of the oxygen / air flow meter 3 to 15.5L / h, and observe through the tail gas ozone indicator so that the tail gas ozone content does not exceed 2.5mg / L. COD of effluent cr Value 91.4mg / L, COD removal rate 99%; effluent chroma 10, odorless, Ca ion 28.7mg / L.

Embodiment 3

[0039] The reaction temperature was controlled at 85°C. The feeding rate of VC wastewater is 2.0 L / h, and the residence time of VC wastewater in the oxidation reactor 9 is 75 minutes. All the other are with embodiment 2. COD of effluent cr The COD removal rate is 72.8mg / L, and the COD removal rate is 99.4%; the effluent is colorless and odorless, and the Ca ion is 26.2mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com