Activation energy radial curing paint for silicon rubber

A technology of active energy rays and curing coatings, which is applied in the direction of coatings, etc., can solve the problems of long curing time, general chemical resistance, poor chemical resistance and wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

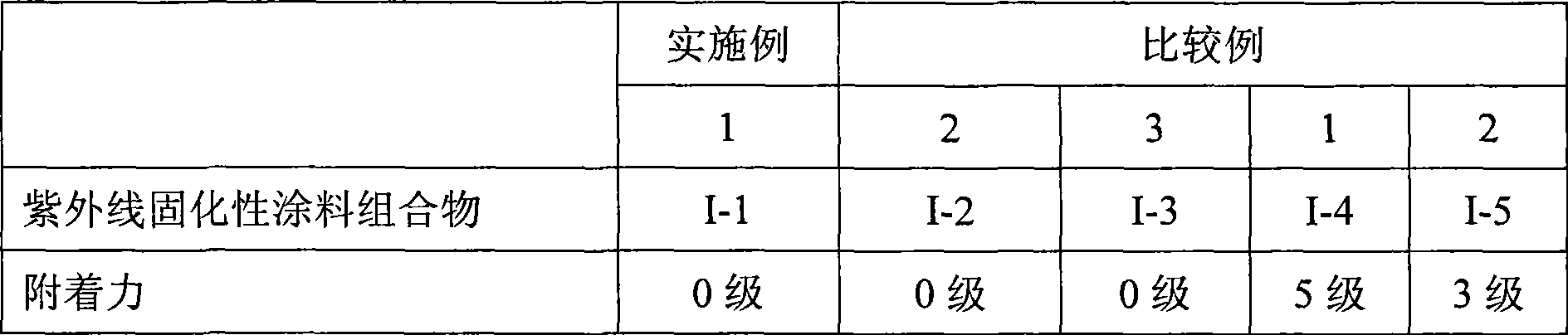

Examples

Embodiment 1

[0069] Add isophorone diisocyanate dropwise to the mixture of dibutyltin dilaurate, polyester diol with a molecular weight of 400 and 3-aminopropyltrihydroxymethylsilane, under the protection of nitrogen, at 50℃~80℃ Stir and react for 4 hours to prepare a transparent polyurethane prepolymer containing siloxane segments, then add hydroxyethyl methacrylate dropwise and keep it warm at 50°C to 80°C for 2 hours to obtain a viscosity of 3000mPa. s / 30℃ modified resin.

[0070] Synthesize 5 parts of gained modified resins, 10 parts of pentaerythritol triacrylate monostearate, 40 parts of difunctional urethane acrylate oligomers, 0.5 parts of 1-hydroxycyclohexyl benzophenone (photoinitiator), 3 parts of 2,4,6-trimethylbenzoyl diphenylphosphorus oxide (photoinitiator), 0.5 parts of leveling agent (BYK-333) are mixed and dispersed in an equal weight mixed solvent of toluene and cyclohexanone, The viscosity was adjusted so that it could be coated with a 4# cup (25° C.) for 13 seconds to...

Embodiment 2

[0072] Except using an equivalent amount of 3-isocyanatotriethoxysilane instead of 3-aminopropyltrimethylsilane in Example 1, the same operation as in Example 1 was carried out to obtain an ultraviolet curable coating composition (I -2).

Embodiment 3

[0074] Add toluene diisocyanate dropwise to the mixture of dibutyltin dilaurate, polyether diol with a molecular weight of 1000 and 3-aminopropyltrihydroxymethylsilane, and stir the reaction at 50℃~80℃ under the protection of nitrogen After 6 hours, a transparent polyurethane prepolymer containing a silane segment was obtained, and then by adding hydroxyethyl acrylate dropwise, and keeping it warm at 50°C to 80°C for 3 hours, a modified polymer with a viscosity of 35000mPa.s / 30°C was obtained. resin.

[0075] Synthesize 5 parts of gained modified resins, 10 parts of pentaerythritol triacrylate monostearate, 40 parts of difunctional urethane acrylate oligomers, 0.5 parts of 1-hydroxycyclohexyl benzophenone (photoinitiator), 3 parts of 2,4,6-trimethylbenzoyl diphenylphosphorus oxide (photoinitiator), 0.5 parts of leveling agent (BYK-333) are mixed and dispersed in an equal weight mixed solvent of toluene and cyclohexanone, The viscosity was adjusted so that it could be coated w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com