Process for synthesizing non-formaldehyde textile easy-care finish resin

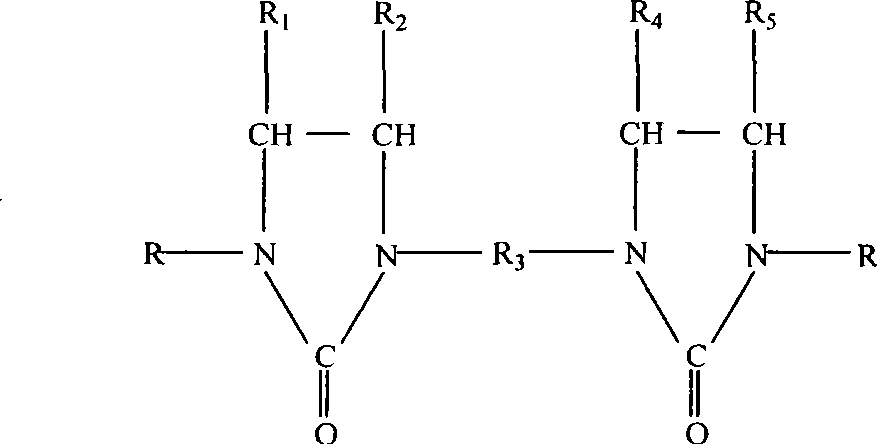

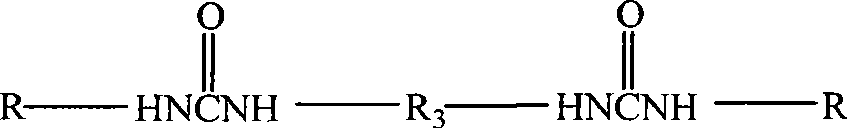

A technology of non-ironing finishing and synthesis method, which is applied in the direction of textiles and papermaking, fiber treatment, plant fiber, etc., which can solve the problems of poor non-ironing effect, decline, yellowing and tearing strength of textile cloth, and achieve the improvement of non-ironing finishing effect, the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

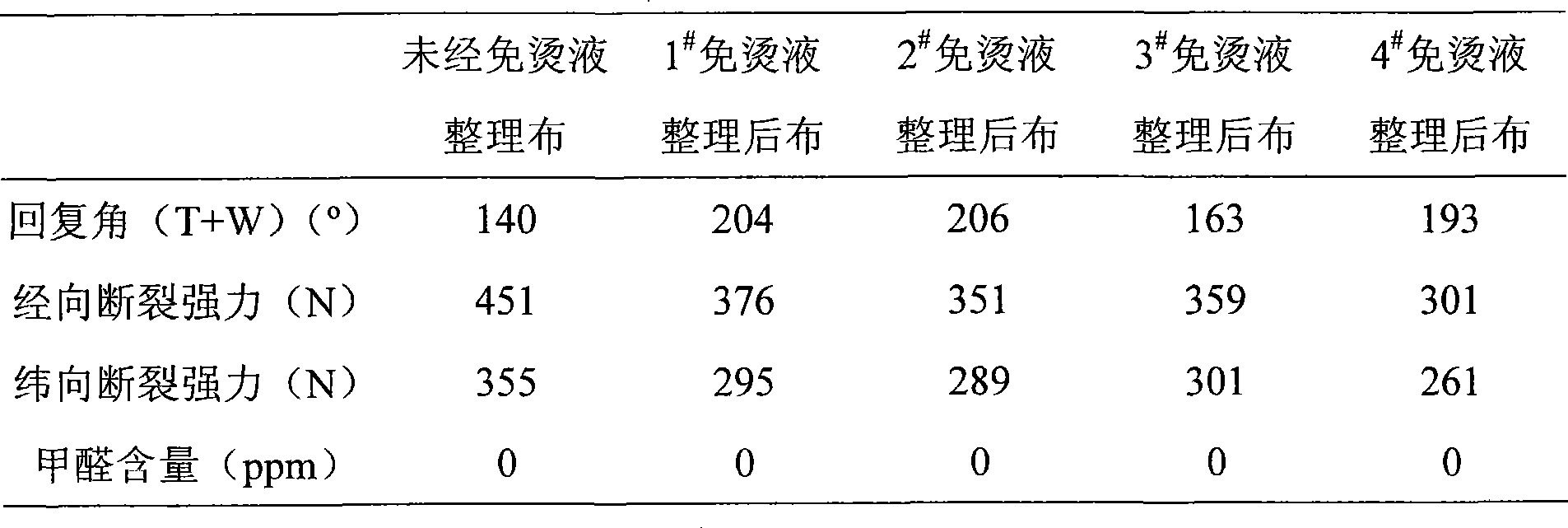

example 1

[0023] 140 grams of glyoxal aqueous solution (glyoxal for industrial use, mass content 40%, pH value 2, the same below), 4 grams of anhydrous sodium acetate, 1.3 grams of anhydrous citric acid and 57 grams of Stir 1,2-hydrazinedicarboxamide, the pH value of the solution is 5.5, keep stirring at 40°C for 5 hours, the pH value hardly changes during the reaction, then cool down to room temperature, add 1 gram of boric acid and stir for 1 hour to obtain a pH value of 4 And a light yellow transparent solution with a solid content of about 40%.

example 2

[0025] Add 140 grams of glyoxal aqueous solution (content 40%), 2.5 grams of anhydrous sodium acetate, 0.8 grams of anhydrous citric acid and 57 grams of 1,2-hydrazine dicarboxamide in a 500 mL three-necked flask and stir, and the pH value of the solution is 5.5 , keep stirring at 40°C for 4 hours, the pH value hardly changes during the reaction, then add 1 gram of ethylenediaminetetraacetic acid disodium salt, 40 grams of methanol and 3 grams of concentrated hydrochloric acid (content 35%), the solution pH value=3.5, Keep stirring at 50° C. for 2 hours, then add an appropriate amount of 40% NaOH solution and deionized water, and finally obtain a light yellow transparent solution with a pH value of 6 and a solid content of about 40%.

example 3

[0026] Example 3 (comparative sample):

[0027] Add 140 grams of glyoxal aqueous solution (content 40%), 4 grams of anhydrous sodium acetate, 1.3 grams of anhydrous citric acid and 68 grams of urea successively in the 500mL there-necked flask and stir, the pH value of the solution=5.5, keep stirring at 50°C for 3 Hour, the pH value hardly changes in the reaction process, add 8 grams of anhydrous citric acid to adjust the pH value of the solution=3.5, then add 40 grams of methyl alcohol, keep stirring at 50 ° C for 2 hours, add an appropriate amount of 40% NaOH solution and deionized water, and finally A yellow-brown transparent solution with a pH value of 6 and a solids content of 40% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com