Multiple-energy source yield distributed energy resource system

A distributed energy, multi-energy technology, applied in the fuel system, the operation mode of the machine, the machine using waste heat, etc., can solve the problem of lowering the grade, and achieve the effect of improving energy utilization efficiency, increasing safety, and reducing dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

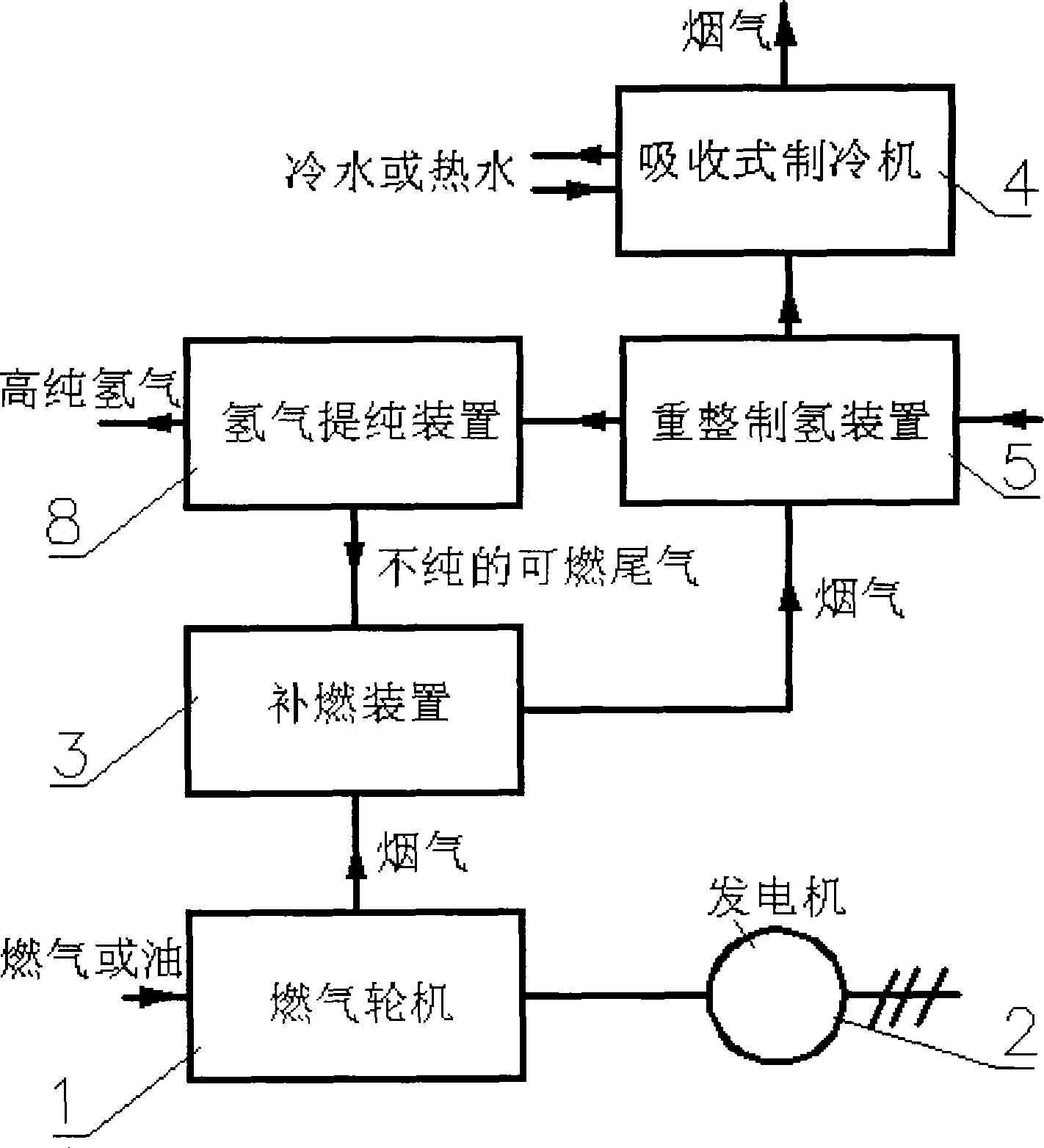

[0027] according to figure 1 As shown, the symbiotic energy system consists of a gas turbine 1, a generator 2, a supplementary combustion device 3, a reforming hydrogen production device 5, an absorption refrigerator 4, and a hydrogen purification device 8, wherein the gas turbine 1 and generator 2 can be integrated together to form a The gas turbine power generation device, the supplementary combustion device 3 and the reforming hydrogen production device 5 can be integrated together to form a composite reforming hydrogen production device. Carrier hydrogen that can continuously provide cold, heat and clean energy for electricity, air conditioning or other purposes. The gas turbine 1 burns gas or oil to generate energy for the generator 2 to generate electricity. The exhaust gas of the gas turbine 1 and the impure combustible tail gas produced after hydrogen purification by the reforming hydrogen production purification device 8 enter the reforming system after supplementary ...

Embodiment 2

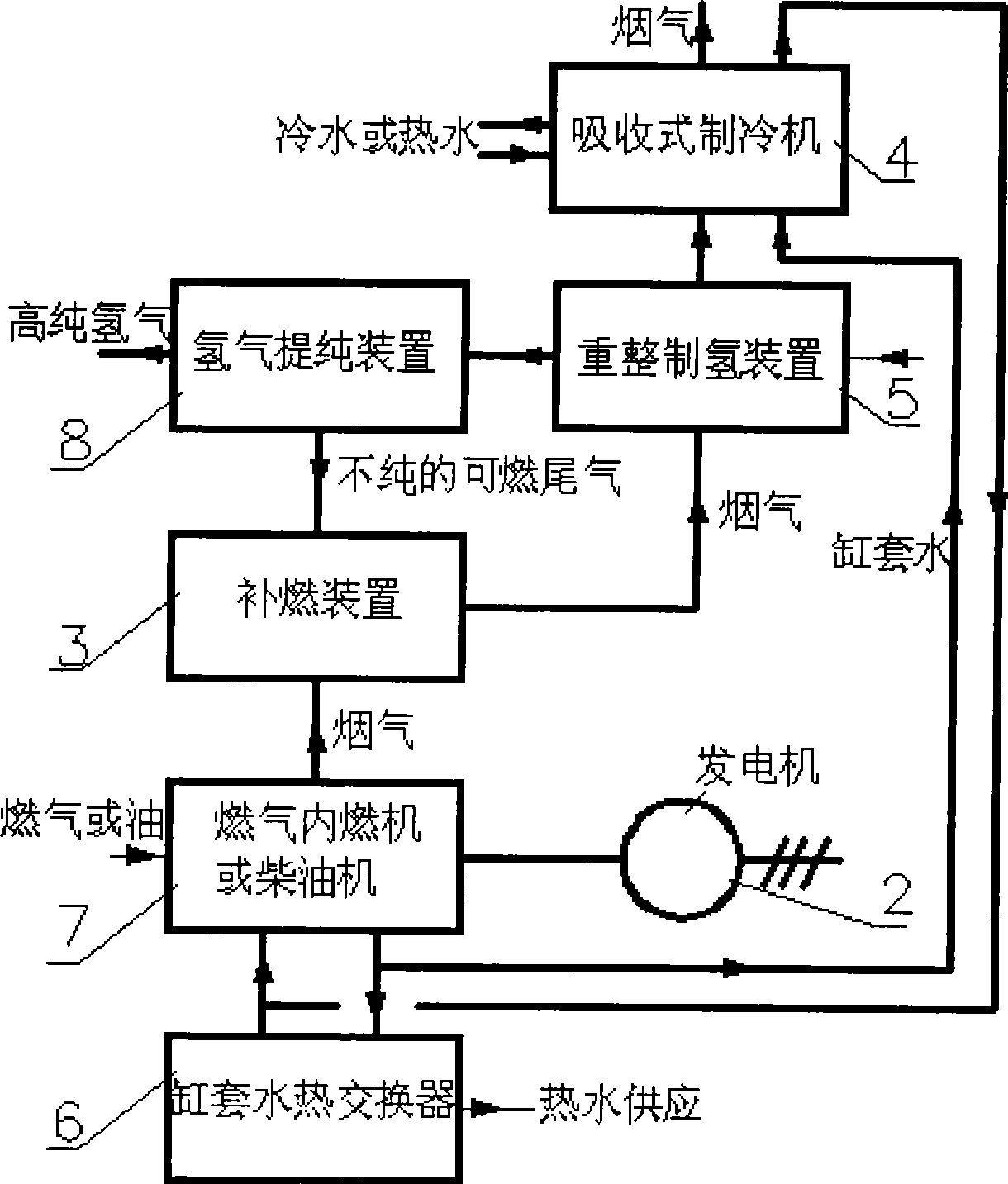

[0029] according to image 3 As shown, the symbiotic energy system replaces the gas turbine with a gas internal combustion engine or a diesel engine, and can be formed by adding a jacket water heat exchanger 6 and correspondingly modifying an absorption refrigerator to adapt to the utilization of low temperature jacket water. The gas internal combustion engine or diesel engine 7 passes through the generator 2 After power generation, the exhaust smoke is mixed with the impure combustible tail gas produced in the purification process of reforming hydrogen production, after supplementary combustion in the afterburning device 3, it enters the reforming hydrogen production device 5 to provide heat for the reforming reaction, and the tail gas passes into the absorption refrigeration Machine 4 refrigeration or heating. The jacket water of the diesel engine enters the low-temperature generator of the absorption refrigerator 4 to cool or generate hot water or enter the jacket water hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com