Compound povidone iodine gel for treating mastitis of milk cattle as well as preparation method and application

A technology for povidone-iodine and mastitis, which is applied in the field of compound povidone-iodine gel for treating dairy cow mastitis and its preparation, and achieves the effects of convenient operation, no sensitization and high drug concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

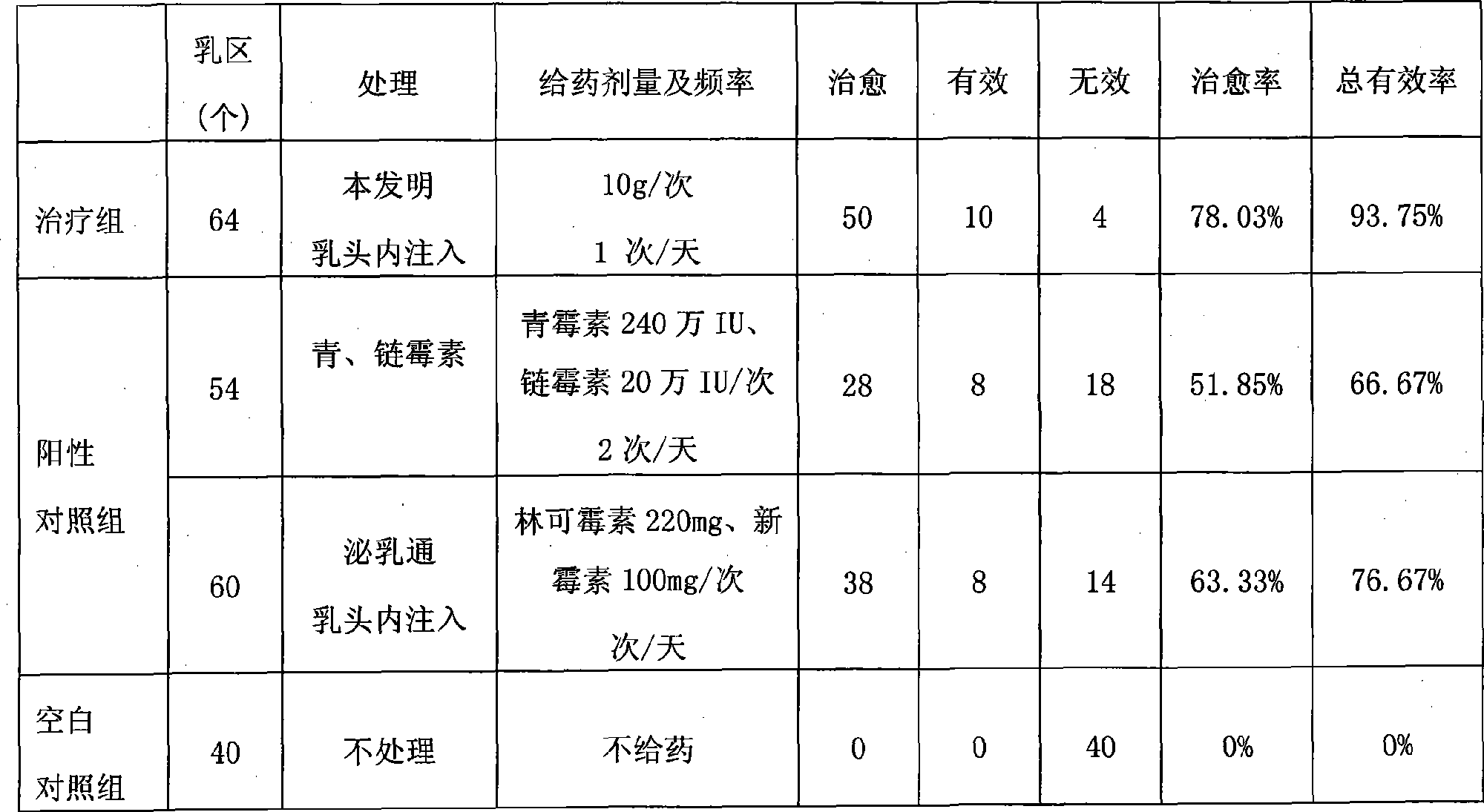

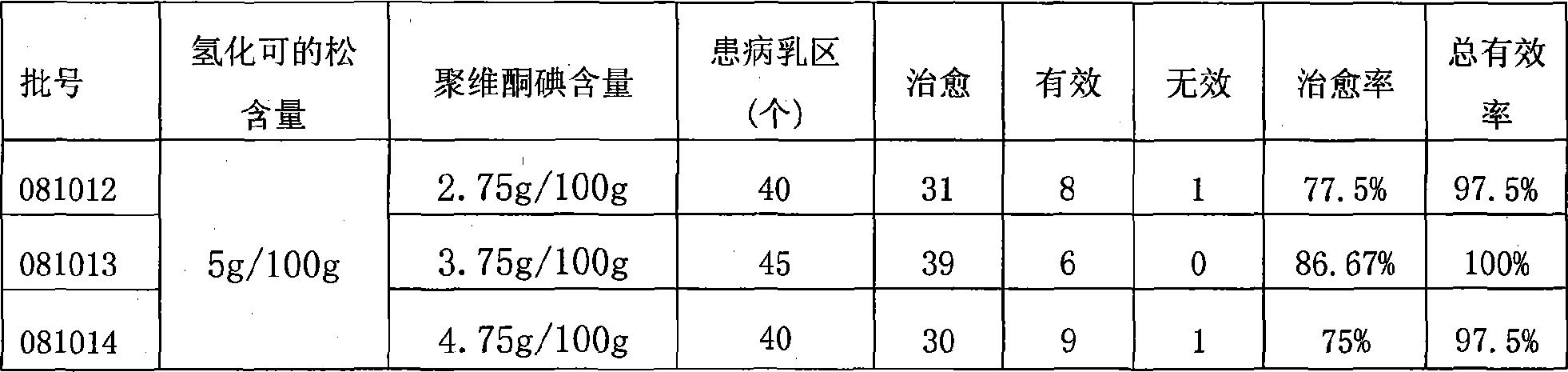

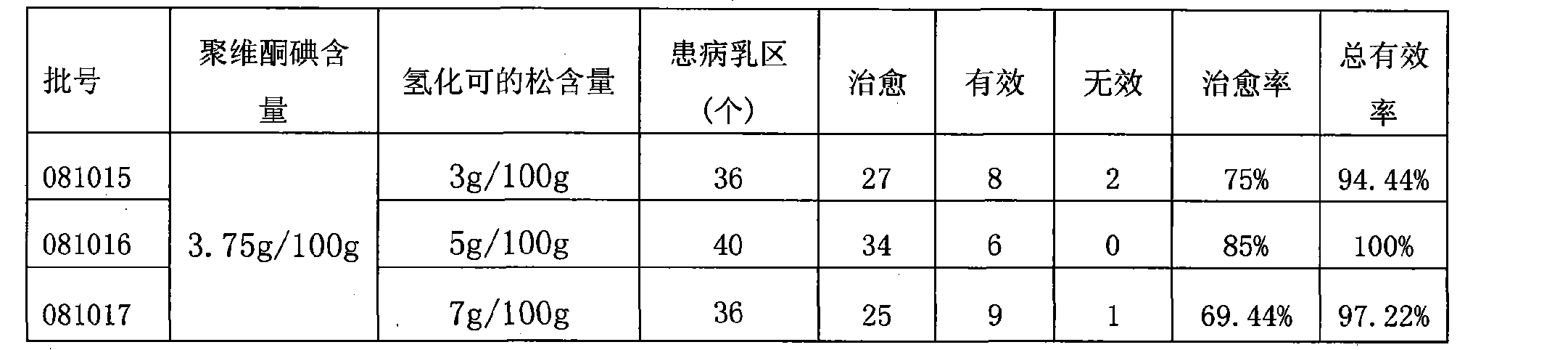

Examples

Embodiment 1

[0070] Prepare the physical addition of 100Kg compound povidone-iodine gel finished product component as follows:

[0071] Carbomer—940 0.1Kg

[0072] 4% povidone iodine 0.2Kg

[0073] Hydrocortisone 1Kg

[0074] Sodium hydroxide 0.05Kg

[0076] Propylene Glycol 5Kg

[0077] Add 93.55Kg of pure water.

[0078] Prepared as follows:

[0079] According to recipe quantity:

[0080] (1) Stir the carbomer with a little water to fully swell;

[0081] (2) Sodium hydroxide is added in the carbomer of step (1) to obtain a gel matrix;

[0082] (3) Povidone-iodine is added in the gel matrix that step (2) obtains, stir;

[0083] (4) Potassium iodate is made into solution with a little water and hydrocortisone and propylene glycol are mixed and added in the product of step (3) gained;

[0084] (5) Add pure water and mix well to get the finished product.

[0085] In the gel complex finished product that present embodiment produces, every bottle of g...

Embodiment 2

[0087] According to the described step of embodiment 1, in the present embodiment, the physical addition of each component of preparing 100Kg compound povidone-iodine gel is as follows:

[0088] Carbomer—940 0.2Kg

[0089] 4% povidone-iodine 1Kg

[0090] Hydrocortisone 2Kg

[0091] Sodium hydroxide 0.06Kg

[0092] Potassium iodate 0.2Kg

[0093] Propylene glycol 10Kg

[0094] Add 86.54Kg of pure water.

[0095] In the gel compound finished product that present embodiment produces, every bottle of gel agent 500g, every bottle of gel component content: carbomer-940 is 1g, 4% povidone iodine 5g, hydrocortisone 10g, hydroxide Sodium 0.3g, potassium iodate 1.25g, propylene glycol 50g, the total weight of each bottle of gel is 500g.

Embodiment 3

[0097] According to the described step of embodiment 1, in the present embodiment, the physical addition of each component of preparing 100Kg compound povidone-iodine gel is as follows:

[0098] Carbomer—940 0.4Kg

[0099] 4% povidone iodine 2Kg

[0100] Hydrocortisone 3Kg

[0101] Sodium hydroxide 0.06Kg

[0102] Potassium iodate 0.3Kg

[0103] Glycerol 10Kg

[0104] Add 84.24Kg of pure water.

[0105] In the gel complex finished product that present embodiment produces, every bottle of gel agent 500g, every bottle of gel component content: carbomer-940 is 2g, 4% povidone iodine 10g, hydrocortisone 15g, hydroxide Sodium 0.3g, potassium iodate 1.5g, glycerol 50g, the total weight of each bottle of gel is 500g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com