Anti-pulverization medium-high temperature coal gas zinc ferrite desulfurizer and preparation thereof

A technology of zinc ferrite and desulfurization agent, applied in the field of desulfurization agent research and preparation, can solve the problem of insufficient attention and achieve the effect of strong anti-pulverization ability and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

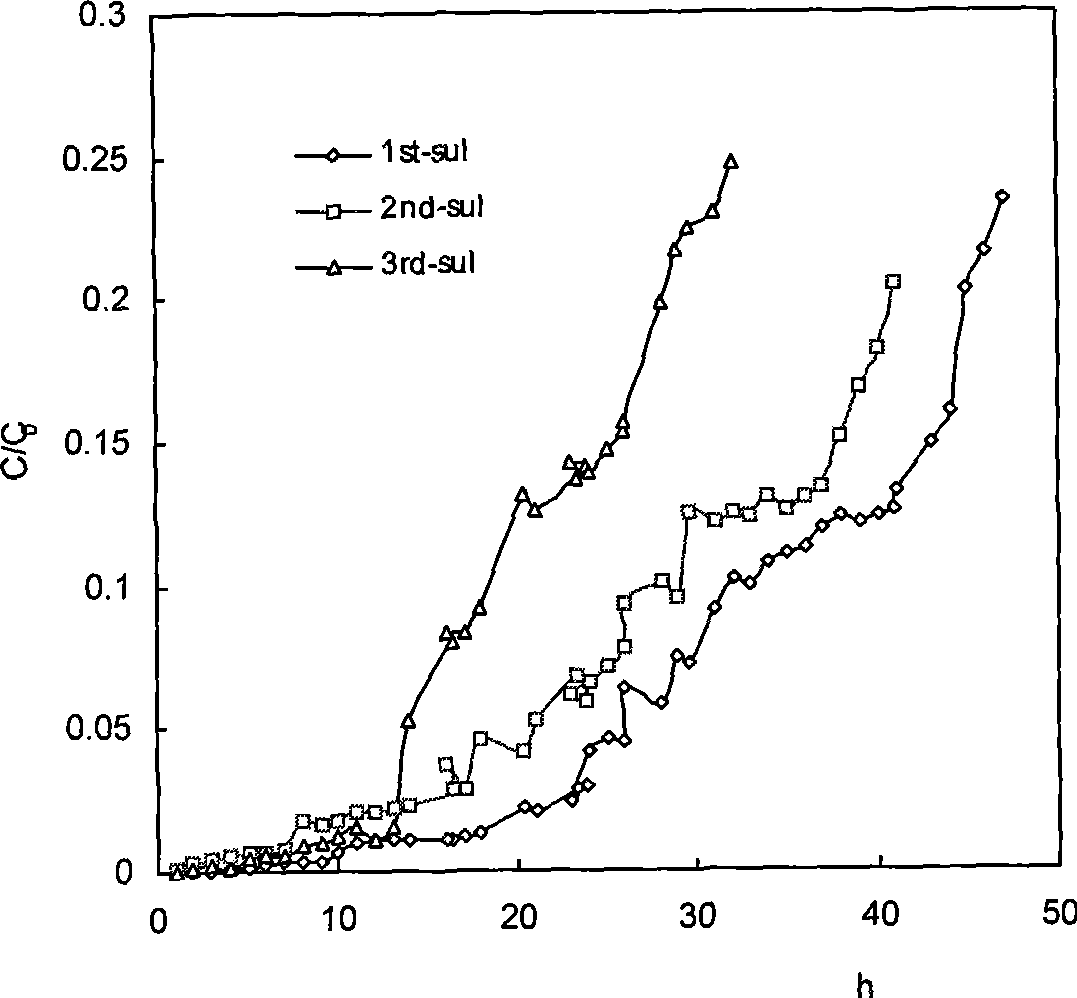

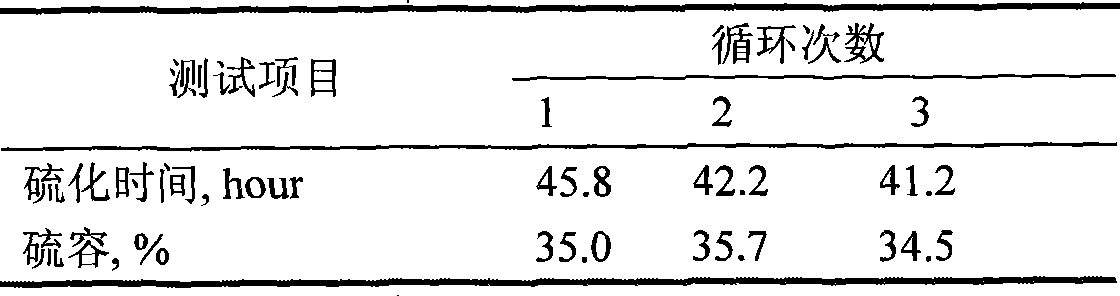

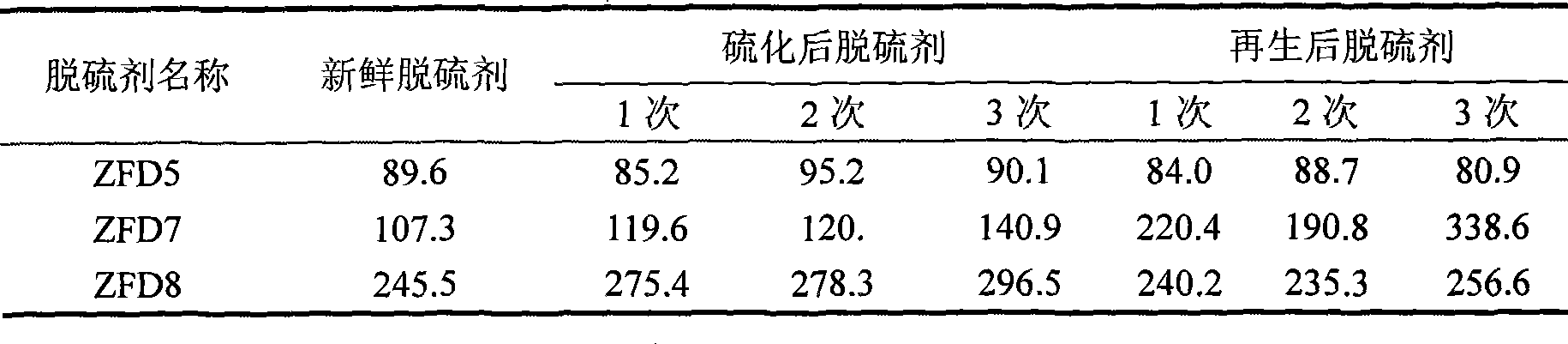

[0043] Example 1: First, use iron and zinc nitrate saturated solution and ammonia water to carry out co-precipitation under the conditions of pH = 9 and precipitation temperature 40°C, then filter and wash, dry at 100°C for 3 hours, and finally reduce the roasting temperature The temperature is controlled at 600° C., and the roasting time is 1.5 hours to prepare the active component of zinc ferrite. Mix 195g of active component zinc ferrite, 90g of kaolin, 18g of pore-forming agent methylcellulose, and 0.3g of lubricant graphite, knead with water, extrude into a column shape of 2-4mm at room temperature, and dry in the shade at room temperature For 24 hours, dry at 150°C for 4 hours, and finally control the roasting temperature at 750°C for 4 hours to obtain the finished zinc ferrite desulfurizer. At a reaction temperature of 400°C and a space velocity of 2000h -1 , the imported hydrogen sulfide concentration is 2000ppm, and the activity evaluation is carried out under the si...

Embodiment approach 2

[0044] Embodiment 2: Firstly, use a saturated solution of nitrate of iron and zinc and ammonia water to carry out co-precipitation under the conditions of pH = 10 and precipitation temperature of 50°C, then filter and wash, dry at 150°C for 4 hours, and finally roast The temperature is controlled at 700° C., and the roasting time is 2 hours to prepare the zinc ferrite active component. Mix 180g of active component zinc ferrite, 90g of bentonite, 36g of pore-forming agent starch, and 0.25g of lubricant, knead with water, extrude into a column shape of 2-4mm at room temperature, and dry in the shade at room temperature for 36 hours. ℃ for 4 hours, and finally control the calcination temperature at 750 ℃ for 4 hours to obtain the finished zinc ferrite desulfurizer. At a reaction temperature of 400°C and a space velocity of 2000h -1 , the imported hydrogen sulfide concentration is 2500ppm, and the activity evaluation is carried out under the simulated Texicao atmosphere. The de...

Embodiment approach 3

[0045] Embodiment 3: Firstly, use a saturated solution of nitrate of iron and zinc and ammonia water to carry out co-precipitation under the conditions of pH=9 and precipitation temperature of 55°C, then filter and wash, dry at 180°C for 4 hours, and finally roast The temperature is controlled at 700° C., and the roasting time is 2 hours to prepare the zinc ferrite active component. Mix 180g of active component zinc ferrite, 90g of brick and tile soil, 18g of pore-forming agent carboxyethyl cellulose, and 0.3g of lubricant graphite, knead with water, extrude into a column shape of 2-4mm at room temperature, and Dry in the shade for 36 hours, dry at 150°C for 4 hours, and finally control the roasting temperature at 750°C for 4 hours to obtain the finished zinc ferrite desulfurizer. At a reaction temperature of 400°C and a space velocity of 2000h -1 , the imported hydrogen sulfide concentration is 2000ppm, and the activity evaluation is carried out under the simulated Texicao a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com