Method for formulating distiller's yeast special for tartary buckwheat wine

A preparation method and technology of tartary buckwheat wine are applied in the preparation of alcoholic beverages, fungi and other directions, which can solve the problems such as no tartary buckwheat wine, and achieve the effects of pure product, fresh saccharification power, and timely distiller's yeast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

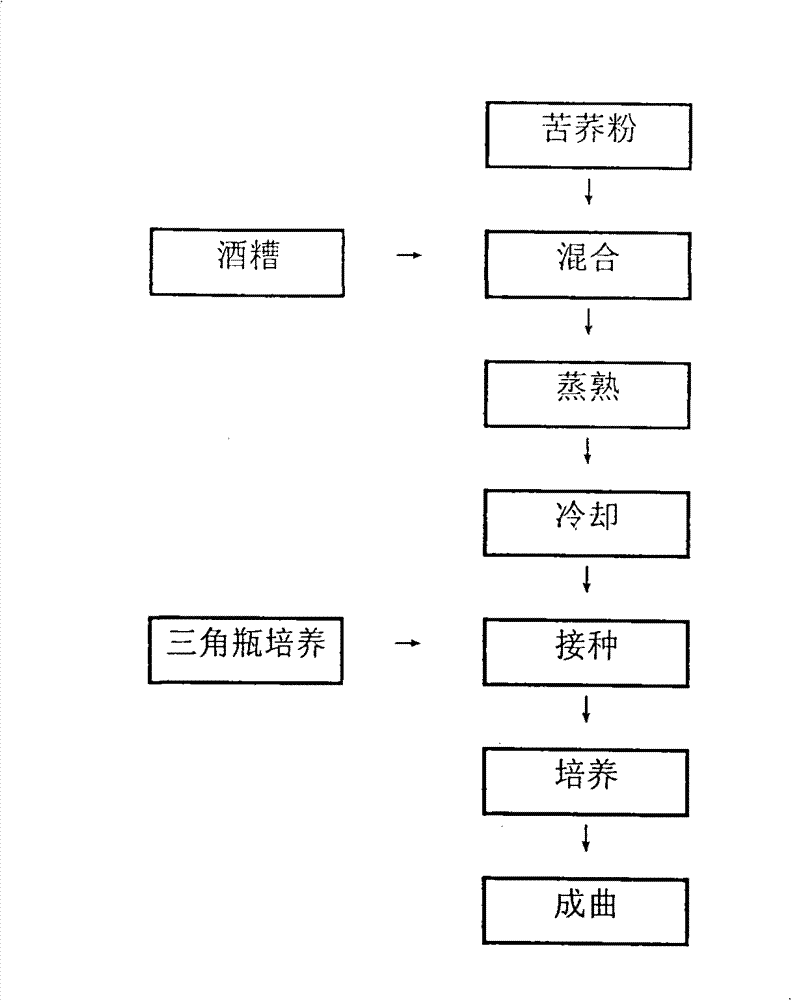

Image

Examples

Embodiment 1

[0025] The preparation method of special distiller's yeast for tartary buckwheat wine comprises the following steps:

[0026] 1. Strains: test tube strains, using Aspergillus oryzae and Aspergillus niger cultivated by "Shanghai Brewing Research Institute", which belong to the special excellent strains used by the Chinese Academy of Sciences for brewing wine, vinegar, soy sauce saccharification and liquefaction;

[0027] 2. Culture medium: a special medium prepared with tartary buckwheat juice; using various culture components and coagulants contained in the self-growth of tartary buckwheat to achieve the purpose of test tube expansion with vigorous growth of bacteria;

[0028] 3. Cultivate the triangle flask:

[0029] (1), triangular flask culture medium, adopt pure tartary buckwheat flour to add a certain dose of distiller's grains, inoculate after high-pressure steam sterilization;

[0030] (2) Cultivate at a constant temperature of 28° C. for 48 hours to mature.

[0031] ...

Embodiment 2

[0039] The preparation method of special distiller's yeast for tartary buckwheat wine comprises the following steps:

[0040] 1. Strains: test tube strains, using Aspergillus oryzae and Aspergillus niger cultivated by "Shanghai Brewing Research Institute", which belong to the special excellent strains used by the Chinese Academy of Sciences for brewing wine, vinegar, soy sauce saccharification and liquefaction;

[0041] 2. Culture medium: a special medium prepared with tartary buckwheat juice; using various culture components and coagulants contained in the self-growth of tartary buckwheat to achieve the purpose of test tube expansion with vigorous growth of bacteria;

[0042] 3. Cultivate the triangle flask:

[0043] (1), triangular flask culture medium, adopt pure tartary buckwheat flour to add a certain dose of distiller's grains, inoculate after high-pressure steam sterilization;

[0044] (2), cultivated at 33°C for 72 hours to mature;

[0045] 4. Distiller's Koji Cultiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com