Preparation of lanthanum-containing AE heat resisting die-casting magnesium alloy

A technology of hot pressing and casting magnesium, which is applied in the field of preparation of lanthanum-containing AE series heat-resistant die-casting magnesium alloys. performance, high temperature performance improvement, and the effect of equalizing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

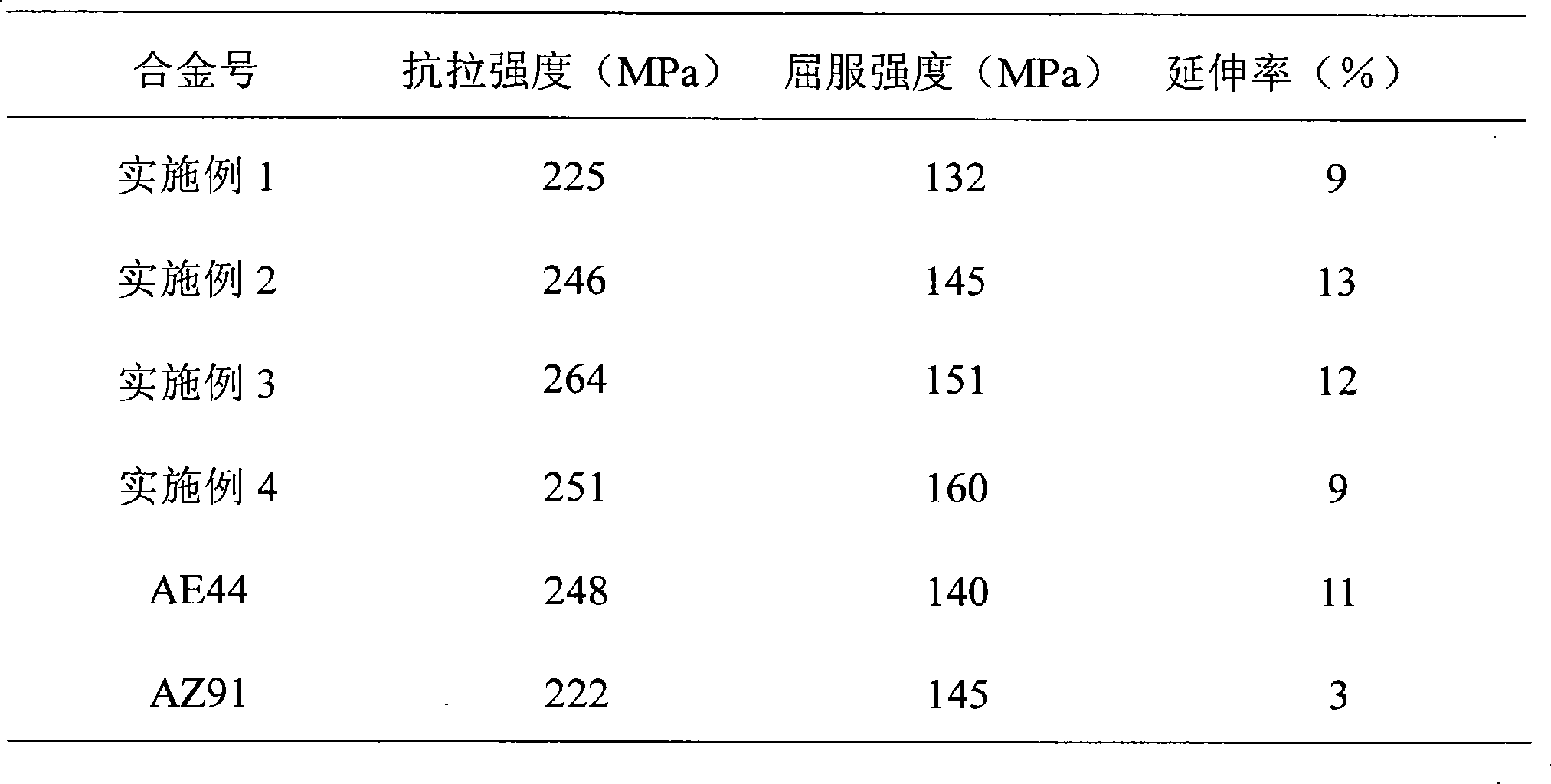

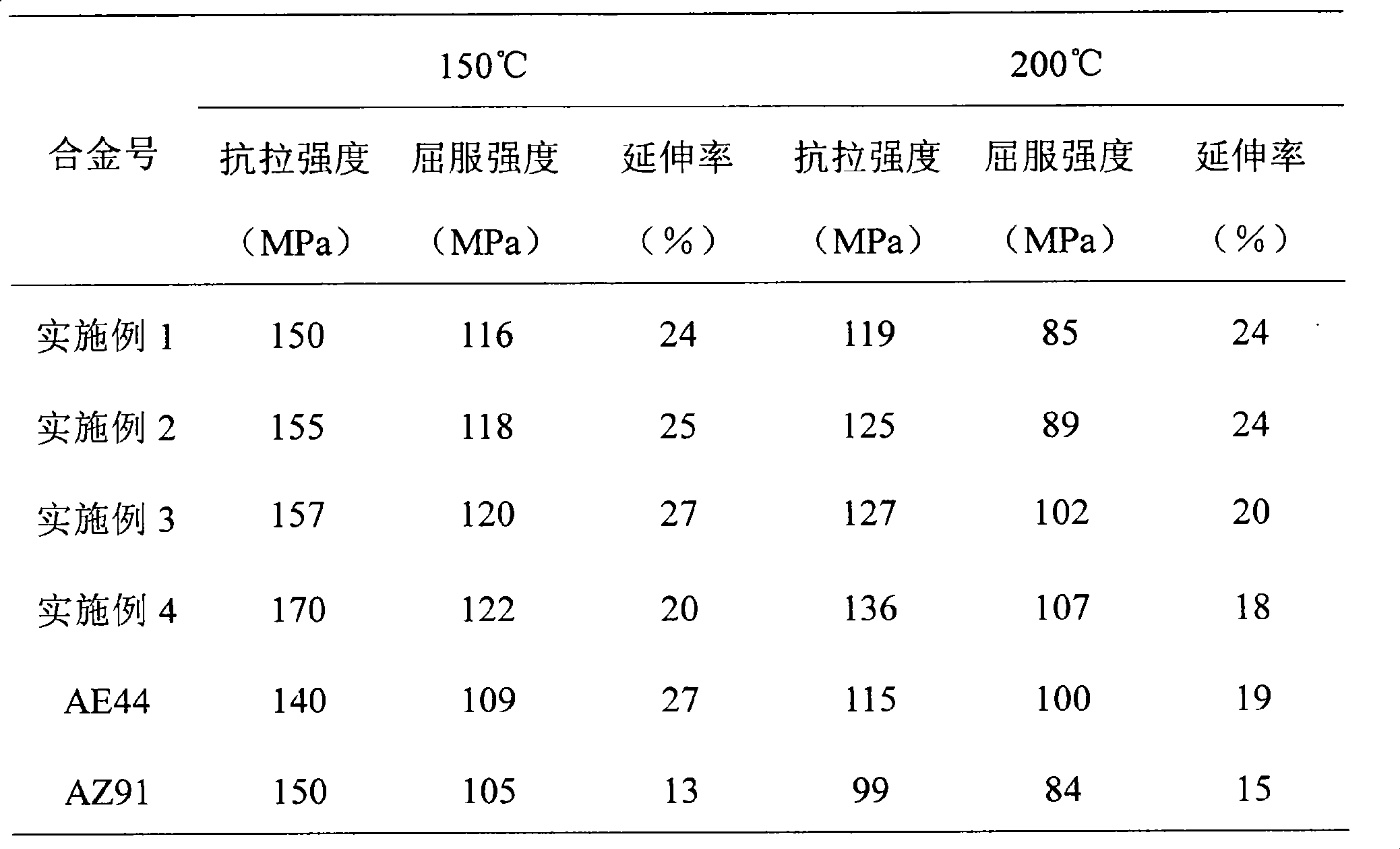

[0013] Weigh aluminum: 3.5%, lanthanum: 1.0%, manganese: 0.2%, the total amount of impurity elements Fe, Cu and Ni is less than 0.03%, and the balance is magnesium. Preheat pure magnesium, aluminum, aluminum-manganese master alloy and magnesium-lanthanum master alloy to 200°C, then put pure magnesium, aluminum, aluminum-manganese master alloy into the crucible preheated to 300°C, and pass through SF 6 :CO 2 The protective gas with a volume ratio of 1:100, when the added charge is completely melted and the melt temperature reaches 720°C, add the magnesium-lanthanum master alloy, and continue to pass the shielding gas, add the magnesium-lanthanum master alloy and melt it, when the temperature rises Stir for 5 minutes at 720°C, then refine with argon for 5 minutes, let stand for 28 minutes after refining, cool the melt to 680°C, and die-cast it on a cold chamber die-casting machine with a clamping force of 280KN to obtain lanthanum-containing AE It is a heat-resistant die-castin...

Embodiment 2

[0015] Weigh aluminum: 4.0%, lanthanum: 2.0%, manganese: 0.3%, the total amount of impurity elements Fe, Cu and Ni is less than 0.03%, and the balance is magnesium. Add magnesium-lanthanum master alloy when the melt temperature reaches 725°C, stir for 8 minutes when the temperature rises to 725°C, then refine with argon gas for 7 minutes, and let stand for 30 minutes after refining. The rest are the same as in Example 1. The properties of the alloy are shown in the table 1 and Table 2.

Embodiment 3

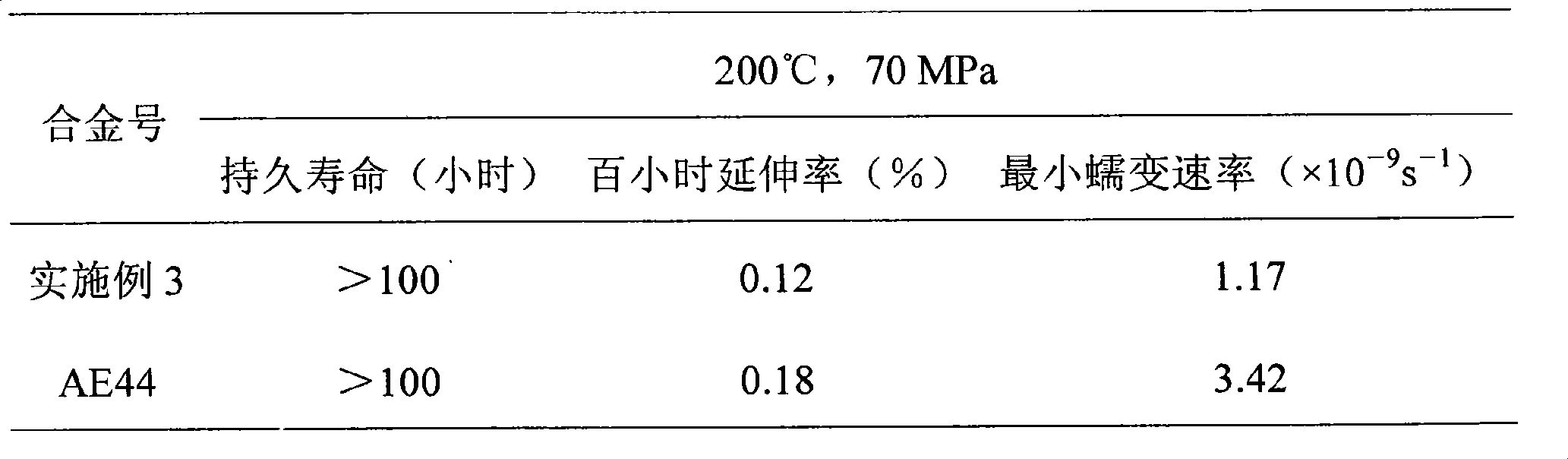

[0017] Weigh aluminum: 4.2%, lanthanum: 4.2%, manganese: 0.4%, the total amount of impurity elements Fe, Cu and Ni is less than 0.03%, and the balance is magnesium. Add magnesium-lanthanum master alloy when the melt temperature reaches 730°C, stir for 10 minutes when the temperature rises to 730°C, then refine with argon gas for 10 minutes, and leave it for 30 minutes after refining. The rest are the same as in Example 1. The properties of the alloy are shown in the table 1. Table 2 and Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com