Method for generating ultraviolet optical frequency comb drive source

A generation method and frequency comb technology, applied to lasers, laser components, electrical components, etc., to achieve high repetition frequency, reduce temperature and vibration requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

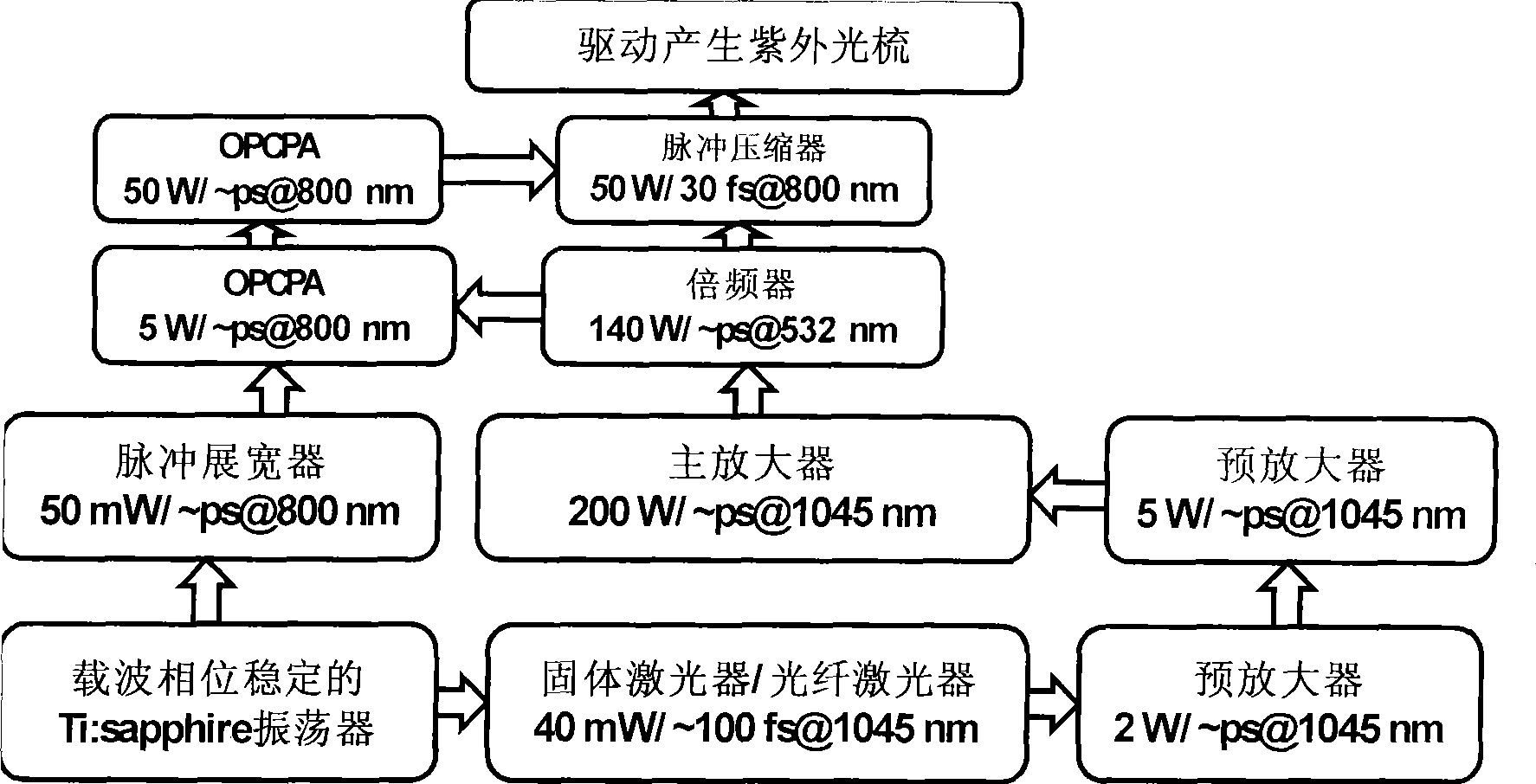

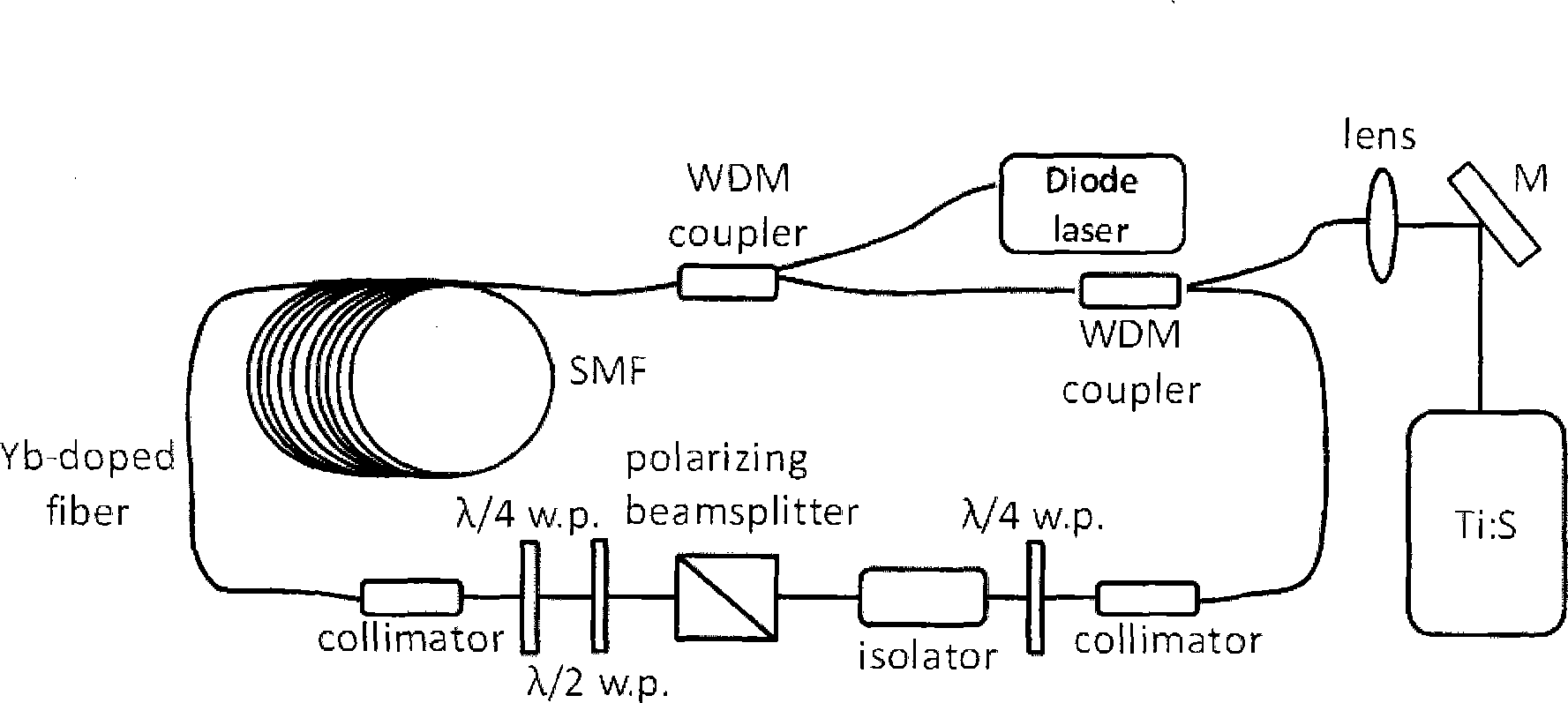

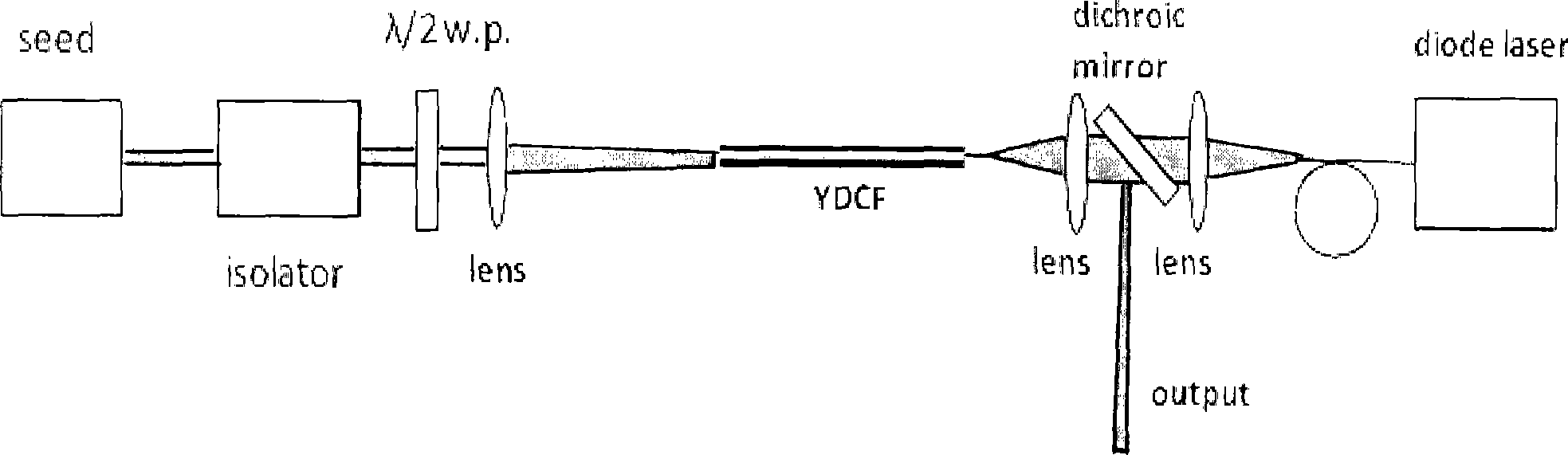

[0017] Embodiment: the steps of this embodiment are as figure 1 The schematic diagram shown, the specific steps are: (1) According to the requirements, select a commercially available Ti:Sapphire laser oscillator with stable carrier phase, whose output spectrum covers a wide frequency range from 650nm to 1100nm. (2) The output laser of the CEP-stabilized Ti:Sapphire laser is split, and part of it is used as a synchronously amplified seed light to drive a fiber laser that uses nonlinear phase deflection and gain modulation to mode-lock. The output center wavelength of the fiber laser is In the 1 micron band, the polarization deflection is induced by the cross-phase modulation between the external pulse and the optical field in the loop, and the cross-phase modulation and harmonic mode-locking technology are used to make the working state of the fiber laser completely modulated by the titanium sapphire laser. The titanium sapphire laser maintains a synchronous state, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com