Centrifugal extracting method for preparing ammonium tungstate solution from soda leach liquor of tungsten contained material

A technology of leaching solution and ammonium tungstate, applied in tungsten compounds, chemical instruments and methods, inorganic chemistry, etc., to achieve the effect of reducing wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

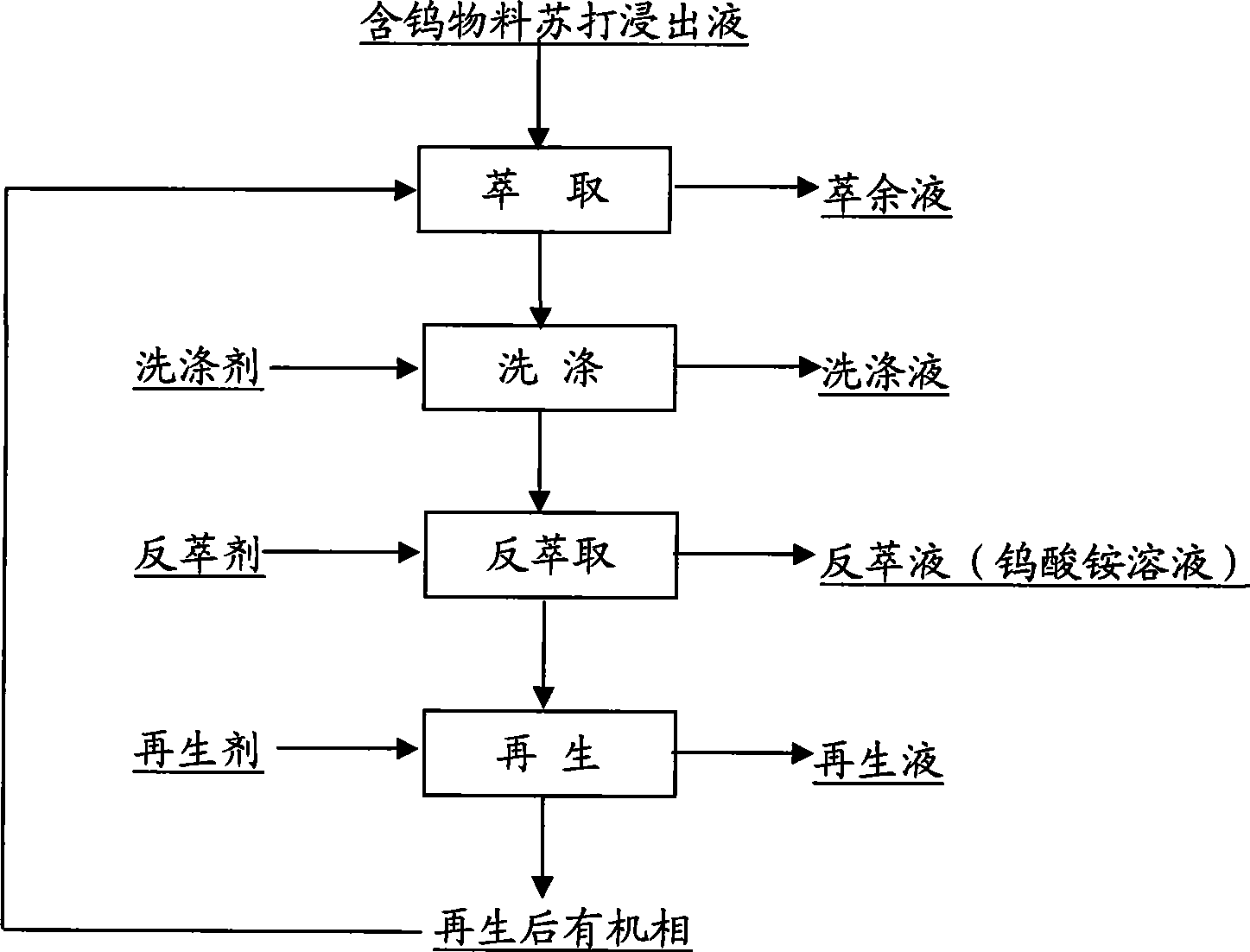

Image

Examples

Embodiment 1

[0029] Composition of tungsten-containing material soda leachate: WO 3 10.0g / L, Na 2 CO 3 20.5g / L, P 0.02g / L, As 0.01g / L, Si0.03g / L;

[0030] Organic phase: pre-prepared organic phase composed of 60% N263+20% 2-octanol+20% sulfonated kerosene (volume percentage concentration), wherein N263 is the product code of domestic quaternary ammonium salt extractant, which is a kind of methyl trimethyl Alkyl ammonium chloride, wherein the carbon atoms in the three alkyl groups are 8-10. Before extraction, the organic phase is contacted with sodium carbonate solution several times to convert the methyltrialkylammonium chloride in the organic phase into the carbonate of methyltrialkylammonium, and the extractant is in the organic phase The volume percentage concentration is 60%, and this organic phase is used as the organic phase of extraction.

[0031]Operation: The above-mentioned organic phase and tungsten-containing material soda leachate are subjected to 7-stage countercurrent ...

Embodiment 2

[0034] Composition of tungsten-containing material soda leachate: WO 3 150.0g / L, Na 2 CO 3 80.3g / L, P 0.020g / L, As 0.011g / L, Si 0.032g / L.

[0035] Organic phase: an organic phase whose composition is 10% methyl trinonyl ammonium chloride + 10% sec-octanol + 80% sulfonated kerosene (volume percentage concentration) is prepared in advance. Before extraction, the organic phase is contacted with sodium carbonate solution several times to convert the methyltrinonylammonium chloride in the organic phase into the carbonate of methyltrialkylammonium, and the extractant is in the organic phase The volume percentage concentration is 10%, and this organic phase is used as the organic phase of extraction.

[0036] Operation: The above-mentioned organic phase and tungsten-containing material soda leachate are subjected to 15-stage countercurrent extraction under the condition of a flow ratio of 10 / 1. The extraction equipment is an annular centrifugal extractor, and the negative tungst...

Embodiment 3

[0039] Composition of tungsten-containing material soda leachate: WO 3 100.2g / L, Na 2 CO 3 90.5g / L, P 0.13g / L, As 0.04g / L, Si 0.24g / L.

[0040] Organic phase: an organic phase whose composition is 60% methyl trioctyl ammonium chloride + 20% sec-octanol + 20% sulfonated kerosene (volume percentage concentration) is prepared in advance. Before the extraction, the organic phase is contacted with sodium carbonate solution several times to convert the methyl trioctyl ammonium chloride in the organic phase into the carbonate of methyl trialkyl ammonium, and the extractant is in the organic phase The volume percent concentration is 60%, and this organic phase is used as the organic phase of extraction.

[0041] Operation: The above organic phase and tungsten-containing material soda leachate are subjected to three-stage countercurrent extraction under the condition of a flow ratio of 1.5 / 1. The extraction equipment is an annular centrifugal extractor, and the negative tungsten o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com