Manufacturing method of gate-splitting type flash memory

A split-gate flash memory and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems that the control gate oxide layer cannot be thinned, and it is impossible to obtain the control gate oxide layer. The effect of reducing the thickness and enhancing the control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

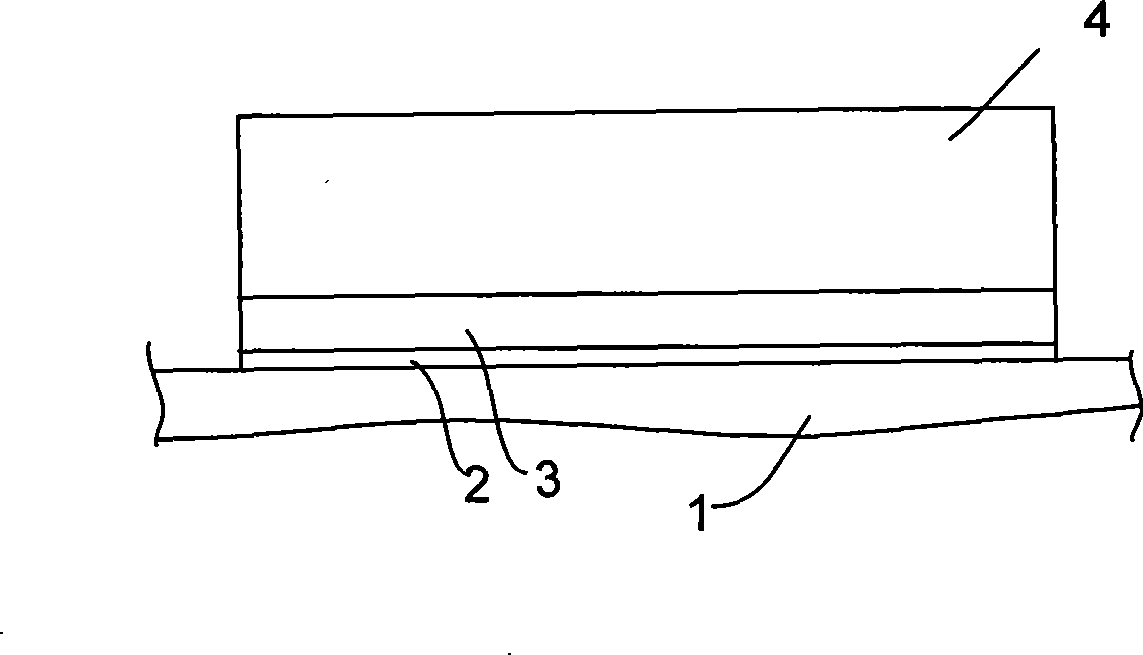

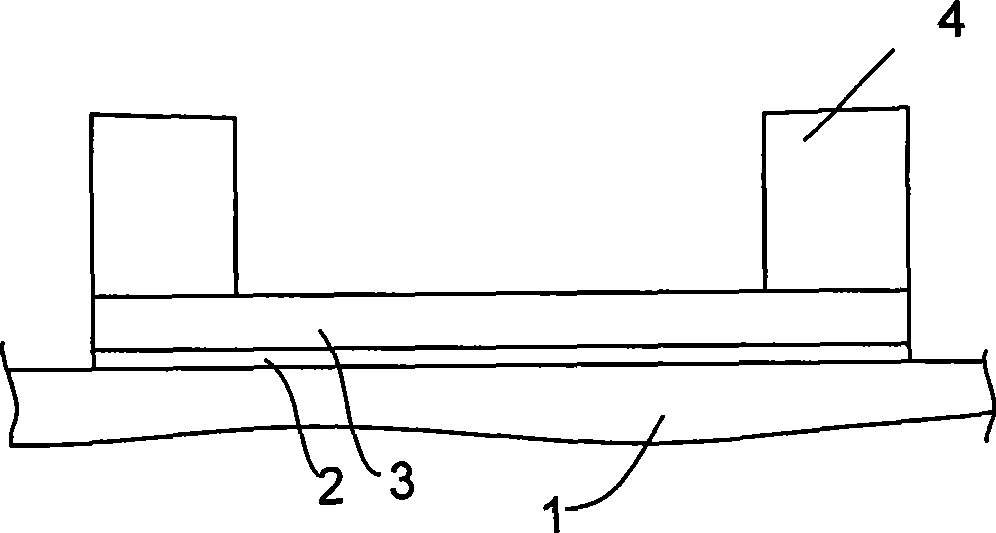

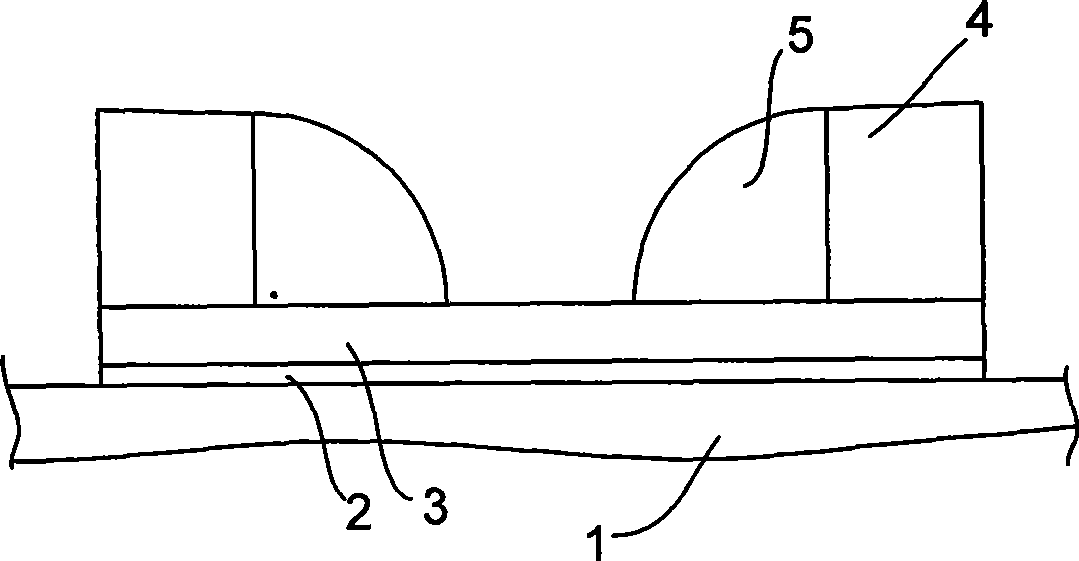

[0034] see Figure 1A As shown in the cross-sectional view of the manufacturing process, a single crystal silicon substrate 1 is provided, and the oxide layer 2 is thermally grown on the silicon substrate 1 to a thickness of about 70A to 150A. Optionally, the silicon substrate 1 Wherein is a P-type substrate and an N-type well is formed in the P-type substrate, or is an N-type substrate and a P-type well is formed in the N-type substrate. After the growth of the thermal oxide layer is completed, a second silicon layer 3 of polysilicon is formed on the oxide layer 2 with a thickness of 100A to 1000A, and a dielectric layer 4 is formed on the second silicon layer 3. The dielectric layer 4 It can be pure oxide or nitride. In this embodiment, the dielectric layer 4 is silicon nitride.

[0035] After completing the above-mentioned oxide layer 2, second silicon layer 3 and dielectric layer 4 processes, a photolithographic mask is formed on the surface of the dielectric layer 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com