Treatment method of odor gas containing sulfur and dust

A treatment method and exhaust gas technology, applied in separation methods, chemical instruments and methods, and the use of liquid separation agents, etc., can solve uneconomical problems, achieve high purification efficiency, and eliminate odor pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

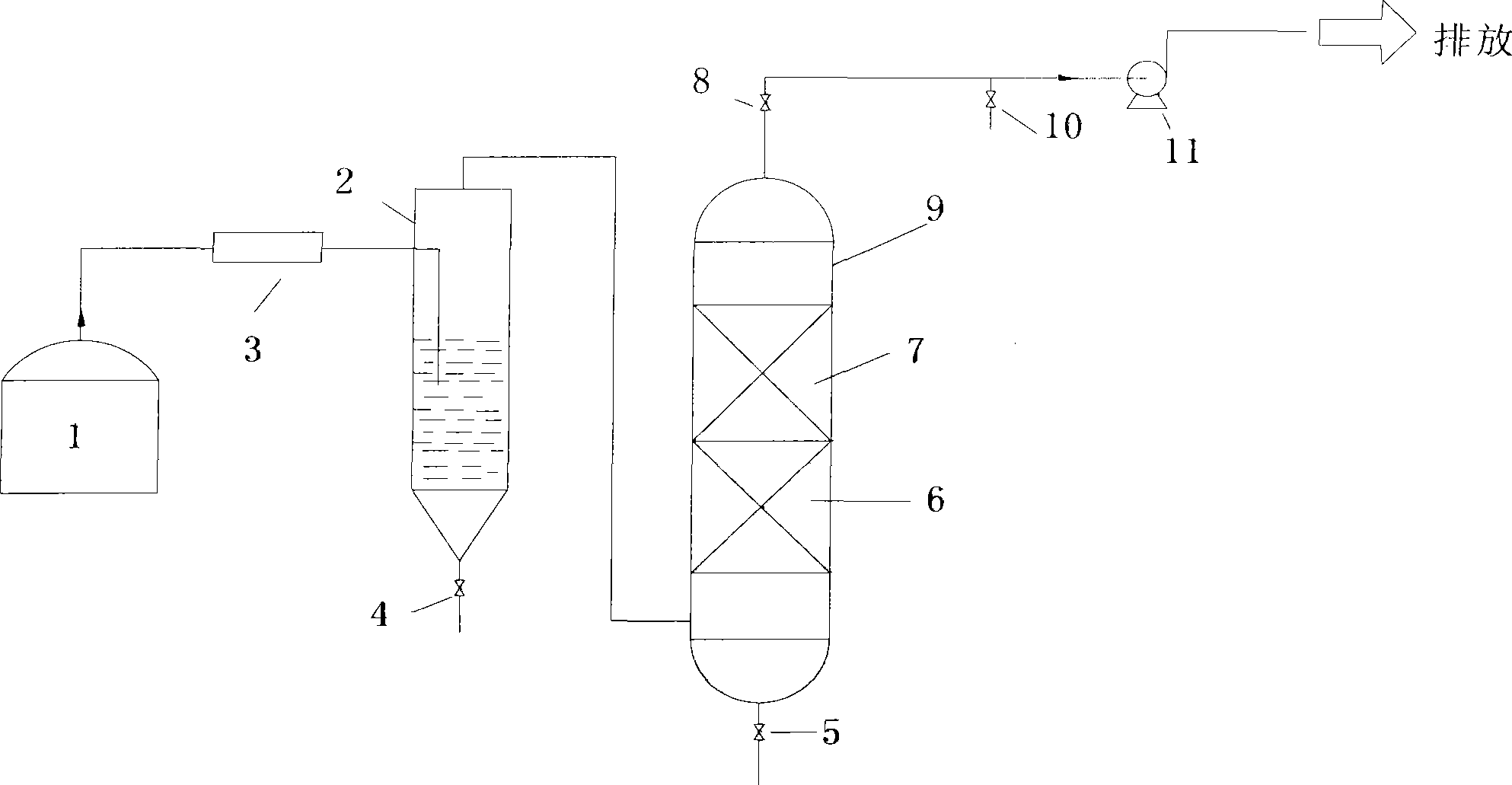

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, wet scrubbing-two-stage adsorption method is used to treat sulfur-containing dust and odorous gas of hydrocarbons, wherein the concentration of sulfide is 300mg / m 3 , the total hydrocarbon concentration is 0.2% (volume ratio), and the dust concentration is 3000mg / m 3 , the exhaust gas temperature is normal temperature. The additive is sodium alkylbenzene sulfonate, and the concentration of sodium alkylbenzene sulfonate is 2 wt%. The space velocity of the exhaust gas in the absorption and washing equipment is 4000h -1 , the liquid-gas ratio is 15L / m 3 . The adsorbent in the lower layer of the adsorption tower is an iron-type desulfurizer with a specific surface area of 713m 2 / g, pore volume 0.39ml / g, average pore diameter 2.2nm. The upper layer is solvent recovery activated carbon with a specific surface area of 1013m 2 / g, pore volume 0.49ml / g, average pore diameter 1.3nm. After treatment by this process, the total hydrocarbon concentrati...

Embodiment 2

[0040] In the fugitive exhaust gas of an industrial facility, the exhaust gas volume is 500m 3 / h, normal temperature, hydrogen sulfide 100mg / m 3 , organic sulfide 50mg / m 3 , dust concentration 4000mg / m 3 . The waste gas is purified by settling box-bubbling absorption tower. The composition of the absorption washing liquid is 5wt% sodium hypochlorite, 1wt% sodium hydroxide, 5wt% nonylphenol polyoxyethylene ether, and 5wt% sodium alkylbenzenesulfonate. The space velocity of the waste gas in the bubbling absorption tower is 2000h -1 , the liquid-gas ratio is 5L / m 3 . After purification by this process, the dust is completely removed, the hydrogen sulfide waste gas is completely purified, and the organic sulfide outlet is less than 1mg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com