Soil bacilli for preventing and controlling fruit tree crown gall and inocula thereof and preparation method

A technology of Agrobacterium and microbial inoculum, applied in the field of agricultural microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

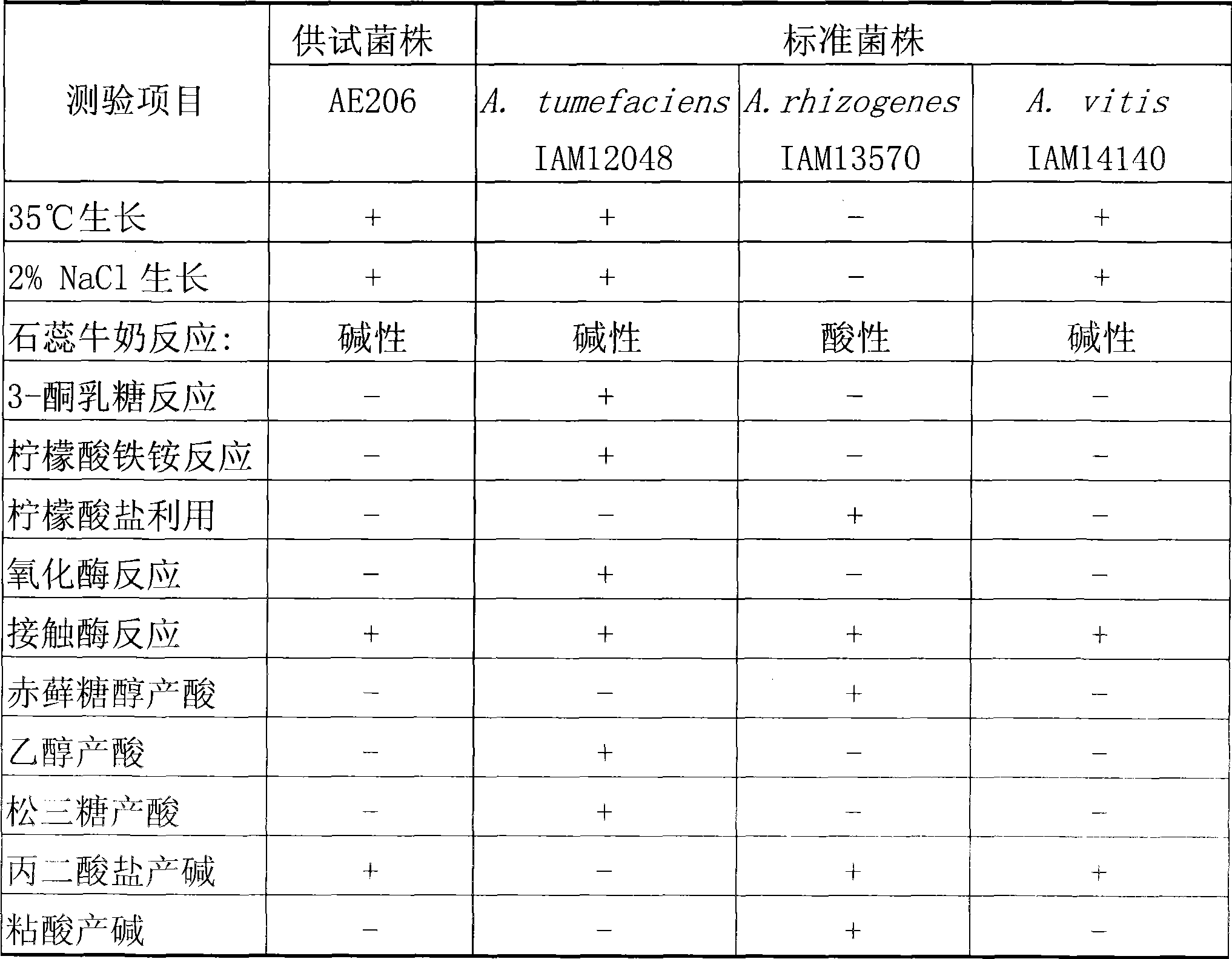

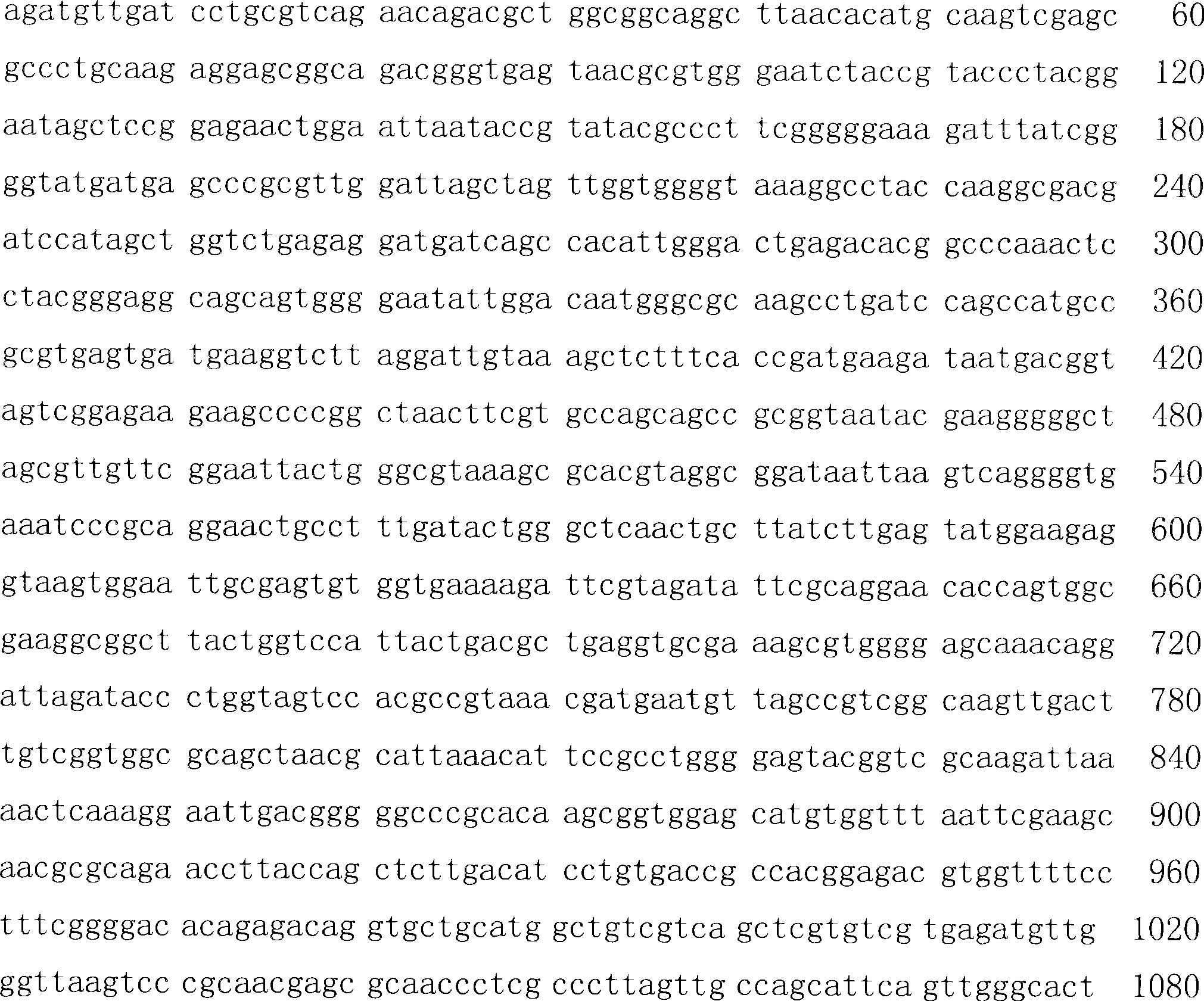

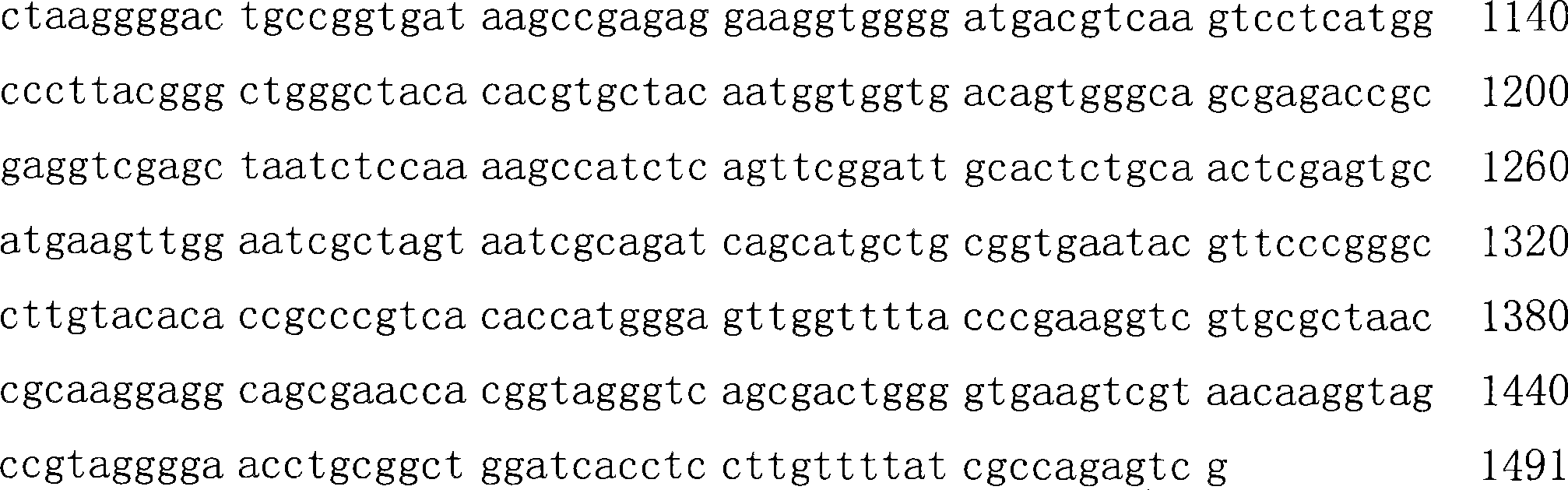

Method used

Image

Examples

Embodiment 1

[0049] The preparation of AE206 fermented liquid comprises the steps:

[0050] (1) Strain activation: Streak the AE206 strain stored at -20°C on the LB plate medium and culture it at 28°C for 24 hours, then pick a single colony and culture it on the LB slant medium for 24 hours at 28°C ,spare.

[0051] (2) Shake flask cultivation: according to 0.03% by weight, the AE206 bacterial classification obtained in step (1) is placed in culture fluid (the composition and weight percentage of culture fluid are: sucrose 0.8%, peptone 0.5%, beef extract 0.5% , yeast powder 0.1%, MgSO 4 0.05%, the rest is water), cultured on a shaker at 28°C and a pH value of 7.0 for 2 days to obtain AE206 bacterial liquid;

[0052] (3) Place the AE206 bacterium solution obtained in step (1) in the seed culture solution according to 5% volume ratio (the composition and weight percentage of the seed culture solution are: 2.0% sucrose, 0.5% sodium glutamate, 0.5% yeast extract, (NH 4 ) 2 SO 4 0.3%, K...

Embodiment 2

[0055] The preparation of AE206 liquid preparation comprises the following steps:

[0056] Get the AE206 fermented liquid prepared by Example 1 and place it in the container, then add xanthan gum and methylcellulose in the AE206 fermented liquid according to the ratio of xanthan gum 0.3g / L, methylcellulose 0.8g / L, mix Evenly.

Embodiment 3

[0058] The preparation of AE206 solid preparation comprises the following steps:

[0059] The AE206 fermentation broth prepared in Example 1 is mixed with the solid filler according to the ratio of parts by weight of 1:4 (the solid filler is mixed by peat soil, xanthan gum and methylcellulose in the following weight percentages: peat soil 99.4%, xanthan gum 0.3%, methyl cellulose 0.3%) were mixed, then shaded and air-dried to make the water content of the mixture 20%, that is, a solid preparation was made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com