Processing method of crystalline silicon texture etch wastewater and system for the same

A treatment method, crystalline silicon technology, applied in the direction of energy wastewater treatment, water/sewage multi-stage treatment, degassed water/sewage treatment, etc., can solve the problems of large economic investment, long time, hindering large-scale application of wastewater treatment methods, etc. , achieve the effect of reducing COD and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

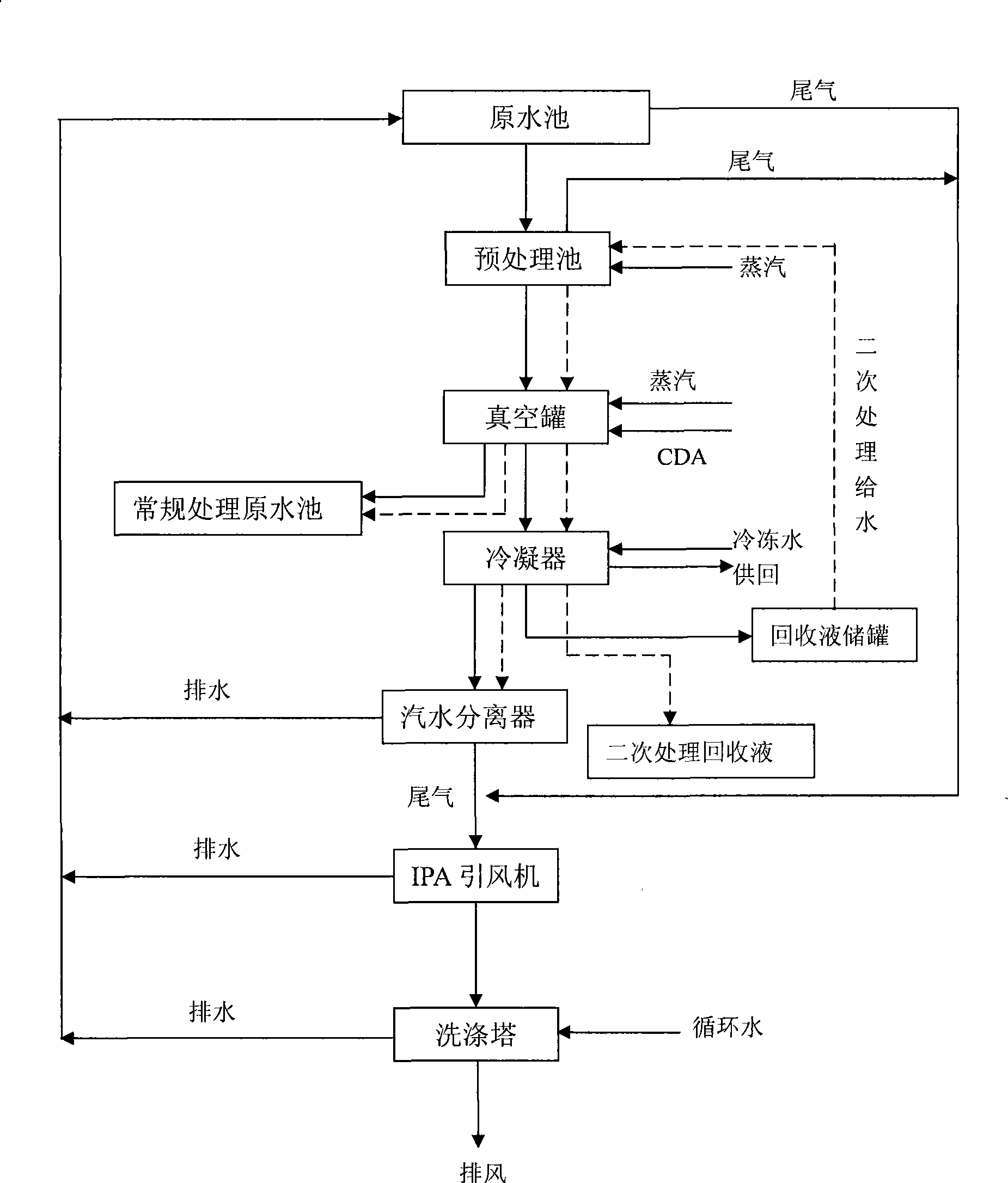

[0035] refer to figure 1As shown, 5 tons of raw water with isopropanol content of 1-2% is transported from the raw water pool of crystalline silicon texturing wastewater to the pretreatment pool and heated to 60±3°C with municipal steam, the pH value is adjusted to 6, and then transported to Vacuum tank, use trace steam to keep it warm, at the same time use compressed air to aerate the vacuum tank, and vacuumize while aerating, maintain the vacuum degree in the vacuum tank at -0.04~-0.085MPa, keep the vacuum The temperature in the tank is 40-60°C, the aeration time is 30 minutes, and the vacuuming time is 40 minutes at the same time. The gas pumped out by the vacuum pump is condensed in the series condenser through the supply of industrial chilled water. The temperature of the industrial chilled water is the condensation The temperature is set at 12°C, and the condensed liquid is periodically discharged to the recovery liquid storage tank. The aerated liquid in the vacuum tan...

Embodiment 2

[0039] Using a process similar to that in Example 1, heat 4 tons of raw water with an isopropanol content of 1 to 2% to 75°C, adjust the pH value to 10, transport it to a vacuum tank, keep it warm with a small amount of steam, and aerate it for a period of time Set it to 45 minutes, and at the same time set the vacuum time to 60 minutes, set the condensation temperature to 9°C, and use a series condenser. The concentration of isopropanol recovered once was determined to be 15.15%, and the COD removal rate was 63.5%. After the secondary treatment, the secondary recovered isopropanol obtained was determined to be 37.31% in concentration.

Embodiment 3

[0041] Using a process similar to that in Example 1, heat 4 tons of primary treatment recovery liquid with a content of isopropanol of about 10% to 75° C., adjust the pH value to 10, transport it to a vacuum tank, keep it warm with a small amount of steam, and expose The gas time is set to 45 minutes, the vacuum time is set to 60 minutes, the condensation temperature is set to 9°C, and a series condenser is used. The secondary recovered isopropanol concentration was determined to be 40.31%, and the COD removal rate was 50.44%.

[0042] The processing method of crystalline silicon texturing wastewater provided by the present invention is compared with existing wastewater treatment methods:

[0043] COD removal usually adopts multi-stage filtration, biological treatment, Fenton reaction and other methods. Multi-stage filtration usually requires a large investment in equipment, and is prone to secondary pollution during the process. Some filter units mainly play a role of interce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com