Urban sludge chemical curing method

A technology of urban sludge and solidification method, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of urban sludge environmental pollution, etc., and achieve the effect of reducing landfill area, low treatment cost, and reducing amount of treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

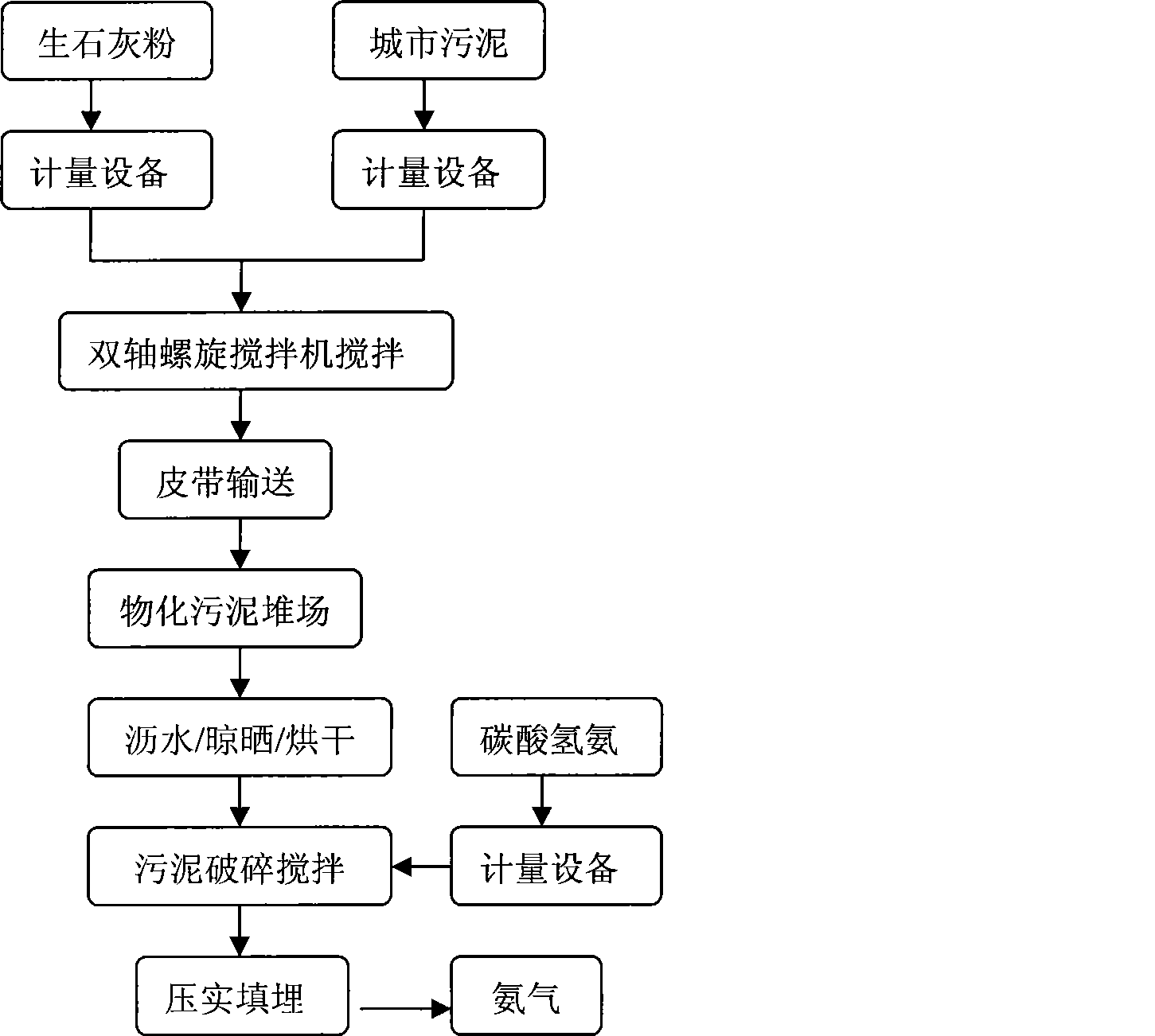

Image

Examples

Embodiment 1

[0040] The municipal sludge chemical solidification method of the present embodiment is as follows:

[0041]The water content of the municipal sludge in this embodiment is 80%, and the contents of heavy metals such as copper and nickel are shown in Table 2. The urban sludge sludge cake is transported to the sludge physical and chemical disposal workshop through a closed tanker, poured into the sludge hopper, and starts the screw conveyor at the lower part of the sludge hopper, adjusts the screw conveyor motor speed, and controls the sludge discharge speed. The municipal sludge continuously flows into the closed twin-shaft mixer; at the same time, the quicklime powder with an activity index of 250 is continuously transported from the storage tank to the closed twin-shaft mixer through a screw metering device and mixed with the municipal sludge evenly. The amount of urban sludge added to the closed twin-shaft mixer is 5 tons, and the amount of quicklime powder added is 0.35 tons...

Embodiment 2

[0050] The municipal sludge chemical solidification method of the present embodiment is as follows:

[0051] The water content of the municipal sludge in this embodiment is 80%, and the contents of heavy metals such as copper and nickel are shown in Table 2. The urban sludge sludge cake is transported to the sludge physical and chemical disposal workshop through a closed tanker, poured into the sludge hopper, and starts the screw conveyor at the lower part of the sludge hopper, adjusts the screw conveyor motor speed, and controls the sludge discharge speed. The municipal sludge is continuously flowed into the closed twin-shaft mixer; at the same time, the quicklime powder crystals with an activity index of 250 are measured by the screw metering device and continuously transported from the storage tank to the closed twin-shaft mixer to mix with the municipal sludge evenly. The amount of urban sludge added to the closed twin-shaft mixer is 5 tons, and the amount of quicklime pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com