Coal water slurry made by combining lincomycin wet bacteria slag and coal

A technology of lincomycin and coal water slurry, which is applied in the field of fuel to achieve the effects of saving coal, preventing pollution, and huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

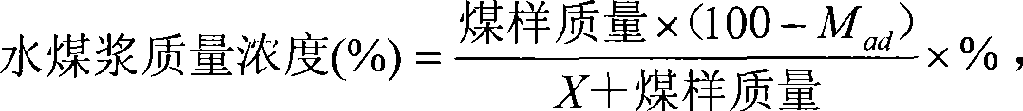

Method used

Image

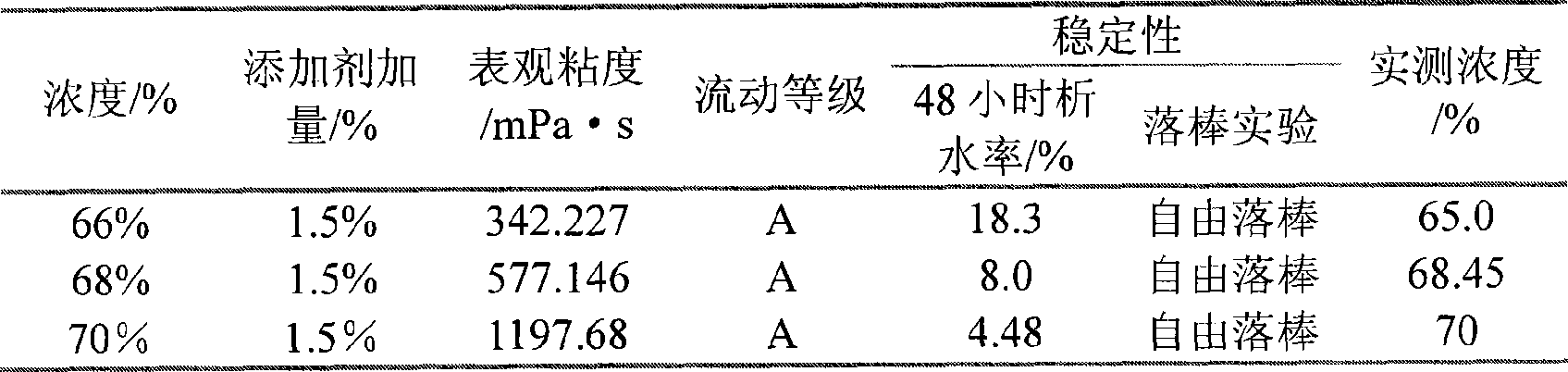

Examples

Embodiment 1

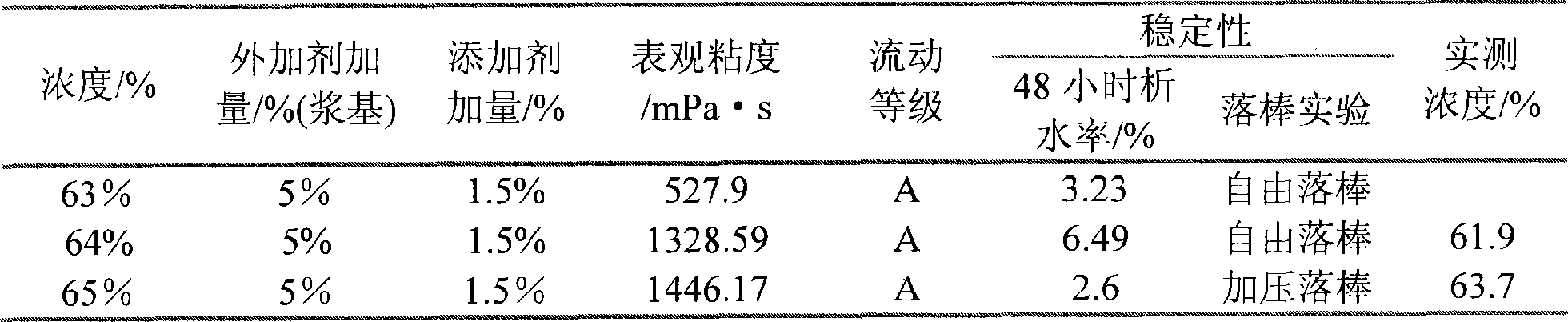

[0013] Embodiment 1: preparation of lincomycin wet slag and coal powder mass concentration is 63% coal water slurry, by weight percentage: coal powder and lincomycin wet slag sum is 63%, additive and water The sum is 37%, wherein the percentage by weight of coal powder and lincomycin wet slag is: coal powder 90%, lincomycin wet slag 10%, additive is 1.5% of coal-water slurry weight, water is water 35.5% of the weight of the coal slurry is made by first mixing additives, water, and lincomycin wet fungus slag to form a mixed liquid, then adding coal powder into the mixed liquid, stirring evenly, and it is ready.

Embodiment 2

[0014] Embodiment 2: the coal water slurry that preparation lincomycin wet fungus residue and coal powder mass concentration is 64% is by weight percentage: coal powder and lincomycin wet fungus residue sum to be 64%, additive and water The sum is 36%, wherein the percentage by weight of coal powder and lincomycin wet slag is: coal powder 90%, lincomycin wet slag 10%, additive is 1.5% of coal-water slurry weight, water is water The coal slurry is made of 34.5% of the weight of the coal slurry. Firstly, the additive, water, and lincomycin wet fungus residue are mixed and stirred evenly to form a mixed liquid, and then coal powder is added to the mixed liquid, stirred evenly, and it is ready.

Embodiment 3

[0015] Embodiment 3: the coal water slurry that preparation lincomycin wet fungus residue and coal powder mass concentration is 65% is by weight percentage: coal powder and lincomycin wet fungus residue sum to be 65%, additive and water The sum is 35%, wherein the percentage by weight of coal powder and lincomycin wet slag is: coal powder 95%, lincomycin wet slag 5%, additive is 1.5% of coal-water slurry weight, water is water 33.5% of the weight of the coal slurry is made. Firstly, the additive, water, and lincomycin wet fungus residue are mixed and stirred evenly to form a mixed liquid, and then coal powder is added to the mixed liquid, stirred evenly, and it is ready.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com