Environment protection type light aggregate and preparation thereof

A lightweight aggregate and environmentally friendly technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of waste of resources, mixed aggregate components, low aggregate quality, etc., to increase value, The effect of high purity and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 , Preparation of environmentally friendly lightweight aggregate from reinforced concrete structure construction waste

[0035] The environment-friendly lightweight aggregate recycled from clay bricks was prepared by the following steps:

[0036] A. Use excavators, loaders, cranes and other mechanical equipment and auxiliary labor to sort out large clay brick walls and waste clay bricks from reinforced concrete construction waste;

[0037] B. Use a rod sieve to remove floating soil, and then remove non-clay brick materials through belt conveyor and manual sorting;

[0038]C. Use modular combined construction waste automatic processing equipment for crushing and iron removal with magnets. The crushing adopts jaw crushing, cone crushing, impact crushing, impact crushing, and hammer crushing;

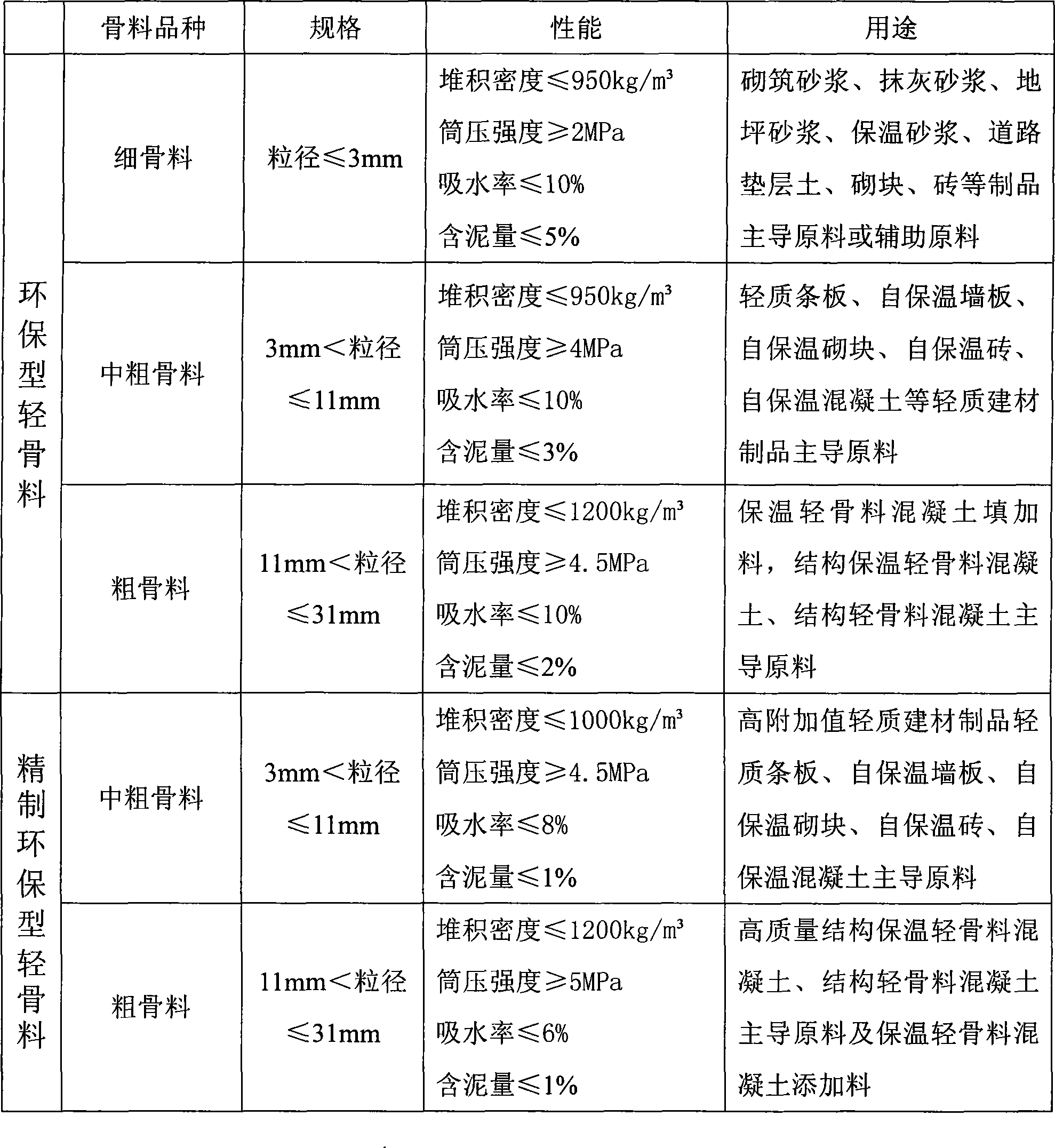

[0039] D. Sieve the crushed clay bricks with screens with apertures of 3mm, 11mm, and 31mm in turn to obtain fine environmental-friendly lightweight aggregate, medium-coa...

Embodiment 2

[0041] Example 2 , Preparation of environmentally friendly lightweight aggregate from brick-concrete structure construction waste

[0042] The environment-friendly lightweight aggregate recycled from clay bricks was prepared by the following steps:

[0043] A. Primary purification: Use excavators, loaders, cranes and other mechanical equipment and auxiliary manual to remove reinforced concrete, ceramics, wood blocks, plastics, steel bars and other non-clay bricks in the brick-concrete construction waste.

[0044] B. Secondary purification: use a high-frequency vibration mass separator with a screen to separate and remove light substances such as wood blocks and plastics in the construction waste after the primary purification, and use a bar sieve to remove floating soil, and pass through a belt conveyor And manual sorting methods to remove non-clay brick materials again.

[0045] C. Use modular combined construction waste automatic processing equipment for crushing and iron...

Embodiment 3

[0048] Example 3 , Refining medium-coarse and environmentally-friendly lightweight aggregate

[0049] The medium-coarse light aggregate of 3mm

[0050] A. Add clean water to the spiral cleaning machine (1.2 meters in diameter and 9 meters in length) to clean medium-coarse, environmentally-friendly lightweight aggregates. Friction between the spiral blades and water rinsing to remove floating ash, fine wood chips and other impurities adsorbed on the light aggregate;

[0051] B. Dry the cleaned medium-coarse lightweight aggregate with a dryer or air-dryer to obtain refined medium-coarse and environmentally friendly lightweight aggregate;

[0052] C. Send the obtained refined medium-coarse environment-friendly lightweight aggregate to an open storage bin or a closed storage tank through a conveyor for storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com