Surface treating agent for binding silastic and plastic, preparation and use method thereof

A technology of surface treatment agent and silicone rubber, which is applied in the field of silicone rubber surface treatment agent, can solve problems such as hidden safety hazards, production burial, damage to the physical structure and chemical properties of rubber, and achieve the effect of avoiding safety hazards and improving adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] At normal temperature and pressure, add γ-aminopropyltriethoxysilane into the toluene solution and stir for 5 minutes to obtain a surface treatment agent for bonding silicone rubber and plastic, in which the ingredient is γ-aminopropyltriethoxy base silane 1g and toluene solution 99g.

[0018] Apply the surface treatment agent to the surface of silicone rubber by brushing, and dry it for 5 minutes under normal temperature and ventilated conditions, so that the toluene evaporates, so as to obtain a uniform coating of amino-containing silane coupling agent, and then apply α- Methyl cyanoacrylate adhesive was spot-coated on the treated silicone rubber, glued to the plastic, and cured at room temperature for 10 minutes to obtain a peel strength of 4.97MPa between the silicone rubber and the plastic.

Embodiment 2

[0020] Under normal temperature and pressure, 10g of benzene, 20g of toluene, 50g of xylene, and 18g of petroleum ether were prepared as a mixed solution, and γ-aminopropyltrimethoxysilane was added to the mixed solution, and stirred for 5 minutes to obtain a silicone rubber surface. treatment agent. Subsequent coating and bonding (using α-cyanoacrylate ethyl ester adhesive) operations are the same as in Example 1. After curing at room temperature for 10 minutes, the peel strength between the silicone rubber and the plastic is measured to be 4.55 MPa.

Embodiment 3

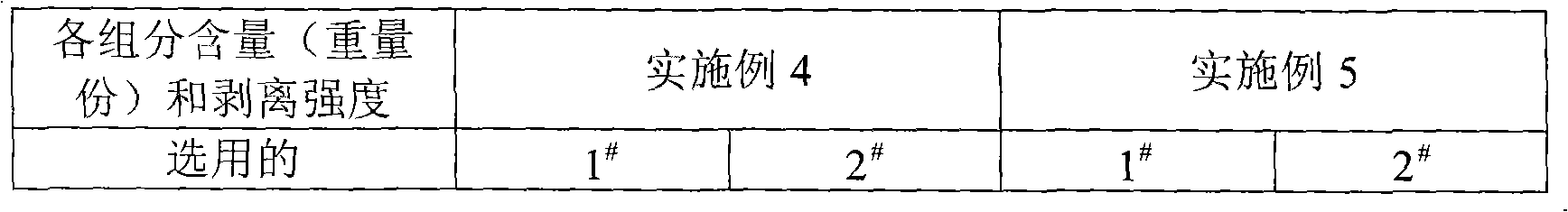

[0022] The method of Example 2 was repeated according to the content of each component specified in Example 3 of Table 1 below, and the test results are listed in Table 1.

[0023] The content of each component (weight

parts) and peel strength

Example 1

Example 2

Example 3

Selected

Amino silane coupling agent

γ-aminopropyl

γ-aminopropyl

Trimethoxysilane

γ-aminopropyl

Amino silane coupling agent

1.0

2.0

4.0

-

10.0

5.0

99.0

20.0

6.0

-

50.0

5.0

-

18.0

80.0

Peel strength (MPa)

4.97

4.55

4.03

fracture form

Silicone rubber break

Silicone rubber break

Silicone rubber break

[0024] Table 1

[0025] From the peel strength test data of each embodiment in the above table 1, the silicone rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com