LED chip and preparation method thereof

A technology of LED chips and chips, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as limiting the external quantum efficiency of GaN-based light-emitting diodes, and achieve the effect of improving external quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

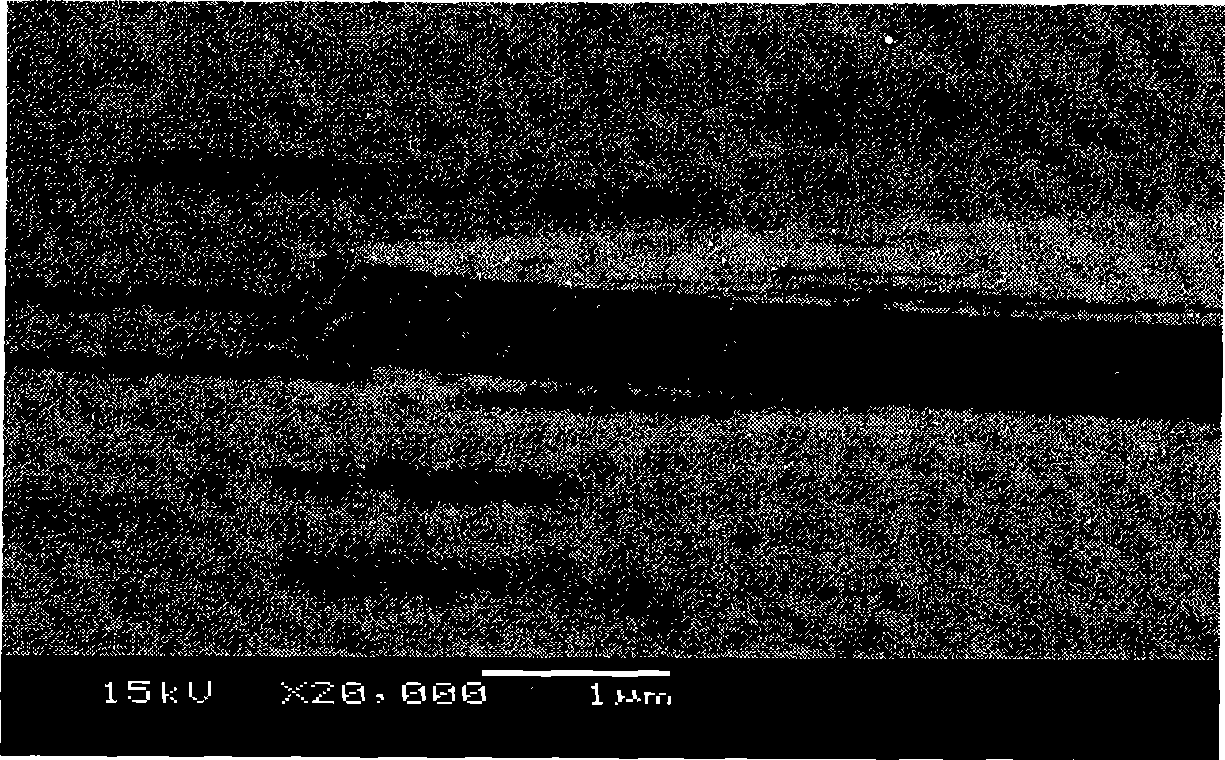

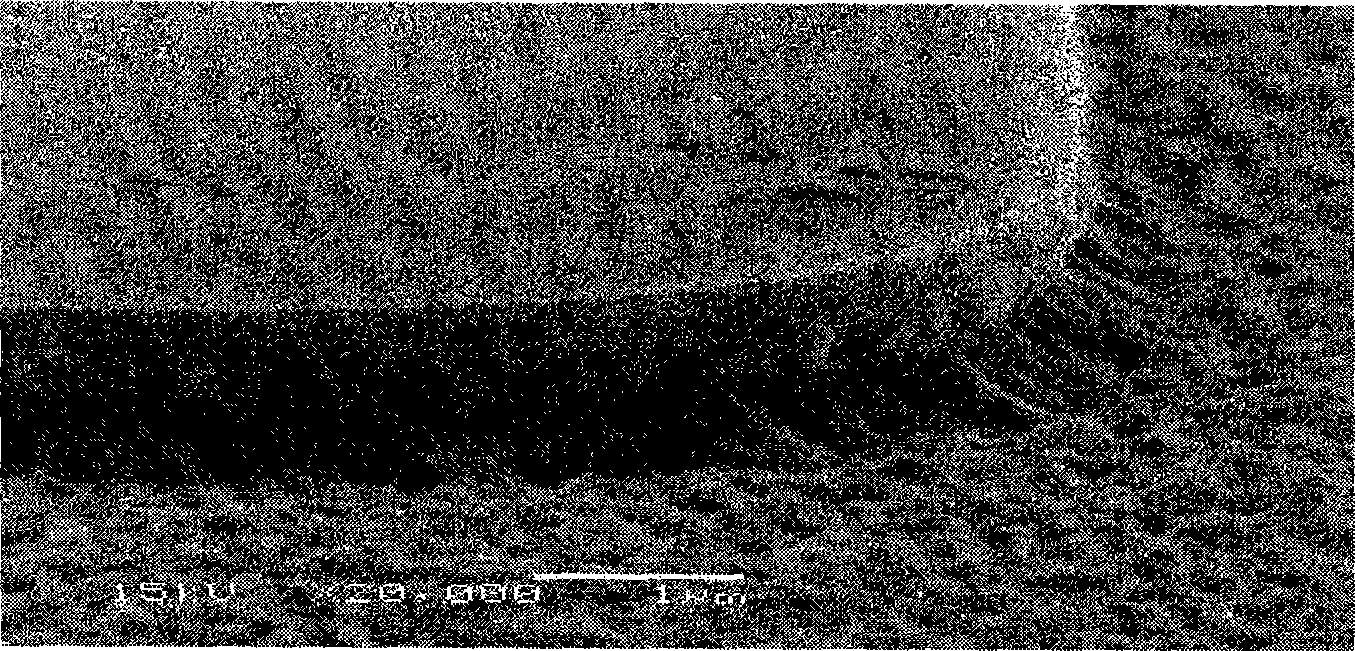

[0019] Example 1, such as figure 2 As shown in FIG. 1 , the side of the etched chip is inclined inward, showing an inverted mesa shape, and an inner chamfer is formed on the side.

[0020] Preparation method of LED chip:

[0021] (1) Using MOCVD epitaxy to grow GaN-based LED structure epitaxial wafers on sapphire substrates;

[0022] (2) Using a high-temperature annealing furnace, anneal the GaN epitaxial wafer at 760°C for 40 minutes in an N2 atmosphere to activate the P-type layer;

[0023] (3) Clean the surface of the GaN epitaxial wafer with acetone, ethanol, stripping solution, 10% hydrochloric acid, and deionized water.

[0024] (4) Photoetching the etched chip pattern on the GaN epitaxial wafer through uniform coating, baking, exposure, and development.

[0025] (5) Evaporate a 400nm Cr / Ni mask layer on the photoetched GaN epitaxial wafer by using an electron beam evaporation platform (E-600 machine of Taiwan Beiqiang Company).

[0026] (6) Remove the photoresist w...

Embodiment 2

[0029] Embodiment 2, the preparation method of LED chip:

[0030] (1) Using MOCVD epitaxy to grow GaN-based LED structure epitaxial wafers on sapphire substrates;

[0031] (2) Using a high-temperature annealing furnace, anneal the GaN epitaxial wafer at 760°C for 40 minutes in an N2 atmosphere to activate the P-type layer;

[0032] (3) Clean the surface of the GaN epitaxial wafer with acetone, ethanol, stripping solution, 20% hydrochloric acid, and deionized water.

[0033] (4) Photoetching the etched chip pattern on the GaN epitaxial wafer through uniform coating, baking, exposure, and development.

[0034] (5) Evaporate a 350nm Cr / Ni mask layer on the photoetched GaN epitaxial wafer by using an electron beam evaporation platform (E-600 machine of Taiwan Beiqiang Company).

[0035] (6) Remove the photoresist with acetone, ethanol, stripper, and deionized water.

[0036] (7), use ICP to etch the GaN to n-GaN layer, and make the chip side after etching inwardly inclined, in ...

Embodiment 3

[0037] Embodiment 3, the preparation method of LED chip:

[0038] (1) Using MOCVD epitaxy to grow GaN-based LED structure epitaxial wafers on sapphire substrates;

[0039] (2) Using a high-temperature annealing furnace, anneal the GaN epitaxial wafer at 760°C for 40 minutes in an N2 atmosphere to activate the P-type layer;

[0040] (3) Clean the surface of the GaN epitaxial wafer with acetone, ethanol, stripping solution, 30% hydrochloric acid, and deionized water.

[0041] (4) Photoetching the etched chip pattern on the GaN epitaxial wafer through uniform coating, baking, exposure, and development.

[0042] (5) Evaporate a 450nm Cr / Ni mask layer on the photoetched GaN epitaxial wafer by using an electron beam evaporation station.

[0043] (6) Remove the photoresist with acetone, ethanol, stripper, and deionized water.

[0044] (7), use ICP to etch the GaN to n-GaN layer, and make the chip side after etching tilt inward, in an inverted mesa shape, etching conditions: ICP po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com