Method for making high brightness LED chip

An LED chip, high-brightness technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as limiting the external quantum efficiency of GaN-based light-emitting diodes, and achieve the effects of improving external quantum efficiency, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

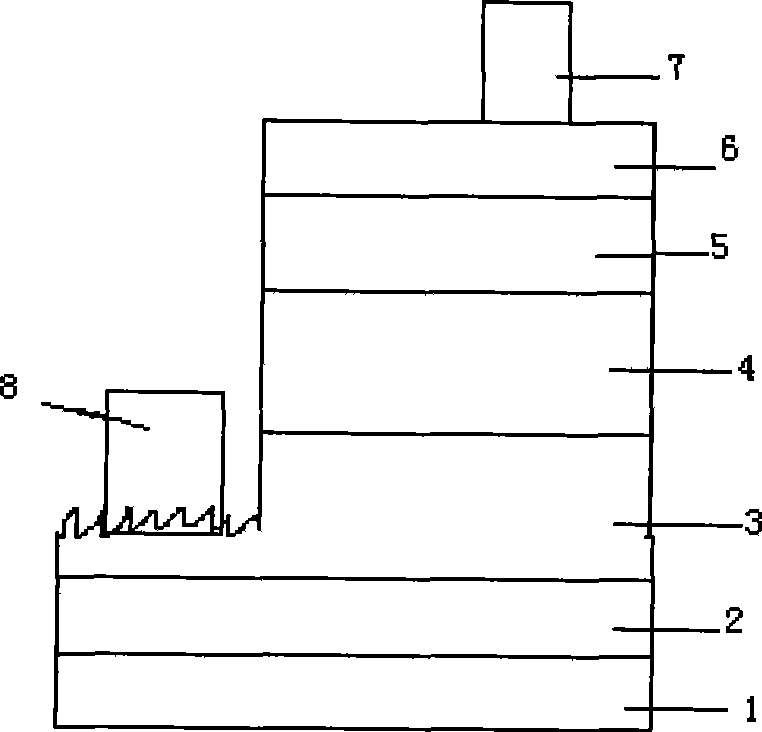

[0041] Example 1, such as figure 1 Shown is a front-mounted high-brightness LED chip, which includes a sapphire substrate 1, a GaN buffer layer 2, an n-type GaN layer 3, an InGaN / GaN multiple quantum well (MQws) active layer 4, a p-type GaN layer 5, from bottom to top. The p-type ohmic contact transparent electrode 6, the p-type ohmic contact metal electrode 7, and the n-type ohmic contact metal electrode 8.

[0042] The manufacturing method of the above-mentioned formally mounted high-brightness LED chip includes the following steps:

[0043] (1) On a sapphire substrate, use MOCVD to epitaxially grow a GaN-based LED structure epitaxial wafer;

[0044] (2) Use PECVD to deposit SiO on the epitaxial wafer 2 film;

[0045] (3) Use SiO 2 The thin film is used as a mask, and the N area pattern of the chip is photoetched on the epitaxial wafer by ICP dry etching technology;

[0046] (4) Use corrosive solution (40%N 4 HF: 40% HF: H 2 The volume ratio of O is 3: 1: 1) Cleaning the SiO th...

Embodiment 2

[0053] Embodiment 2, the manufacturing method of a high-brightness LED chip, including the following steps:

[0054] (1) On a sapphire substrate, use MOCVD to epitaxially grow a GaN-based LED structure epitaxial wafer;

[0055] (2) Use PECVD to deposit SiO on the epitaxial wafer 2 film;

[0056] (3) Use SiO 2 The thin film is used as a mask, and the N area pattern of the chip is photoetched on the epitaxial wafer by ICP dry etching technology;

[0057] (4) Use corrosive solution (40%N 4 HF: 40% HF: H 2 The volume ratio of O is 3: 1: 1) Cleaning the SiO that is not protected by photoresist 2 ;

[0058] (5) Clean the photoresist with stripping liquid;

[0059] (6) Use ICP to etch the N-side steps and the scribe lanes of the chip size to expose the n-GaN mesa;

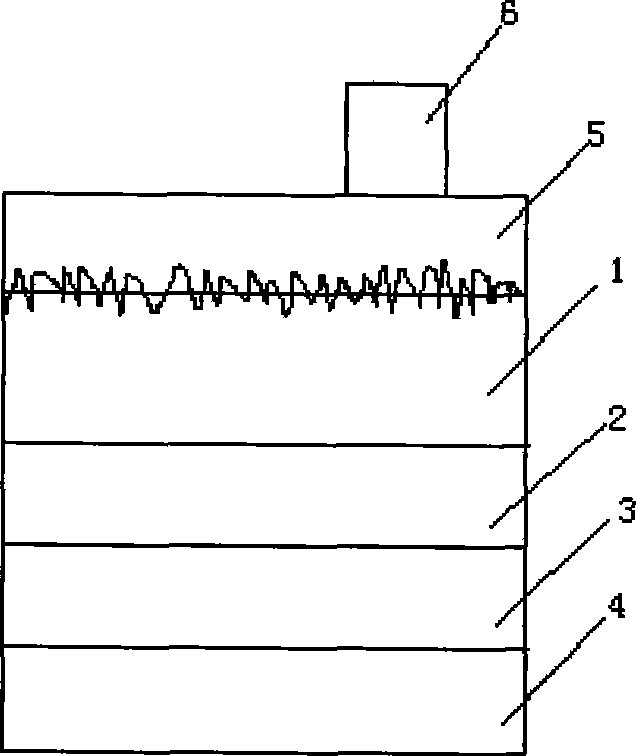

[0060] (7) Use electron beam evaporation equipment to deposit Ti film on the epitaxial surface. The thickness of the Ti film is 300nm. Soak the epitaxial wafer in 30% KOH solution. At room temperature, use ordinary mercury lamp...

Embodiment 3

[0063] Embodiment 3, the manufacturing method of the high-brightness LED chip, including the following steps:

[0064] (1) On a sapphire substrate, use MOCVD to epitaxially grow a GaN-based LED structure epitaxial wafer;

[0065] (2) Use PECVD to deposit SiO on the epitaxial wafer 2 film;

[0066] (3) Use SiO 2 The thin film is used as a mask, and the N area pattern of the chip is photoetched on the epitaxial wafer by ICP dry etching technology;

[0067] (4) Use corrosive solution (40%N 4 HF: 40% HF: H 2 The volume ratio of O is 3: 1: 1) Cleaning the SiO that is not protected by photoresist 2 ;

[0068] (5) Clean the photoresist with stripping liquid;

[0069] (6) Use ICP to etch the N-side steps and the scribe lanes of the chip size to expose the n-GaN mesa;

[0070] (7) Use electron beam evaporation equipment to deposit Ti film on the epitaxial surface. The thickness of the Ti film is 280nm. Soak the epitaxial wafer in 5% hydrochloric acid solution at room temperature. Use ordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com