Metal honeycomb catalyst for purifying diesel motor exhaust gas and preparation method thereof

A diesel engine, metal honeycomb technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. Problems such as poor thermal conductivity of bluestone, to achieve the effect of widening the working temperature range, improving catalytic activity, and small air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

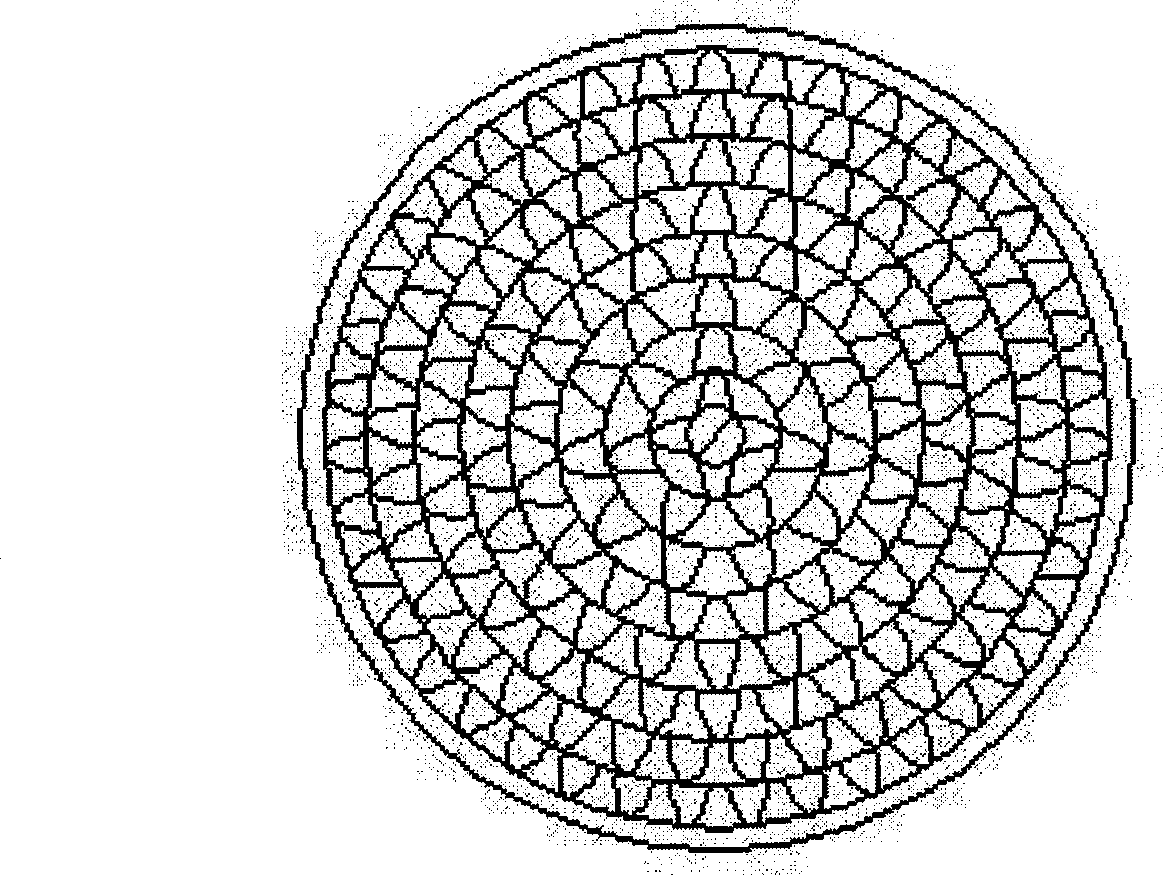

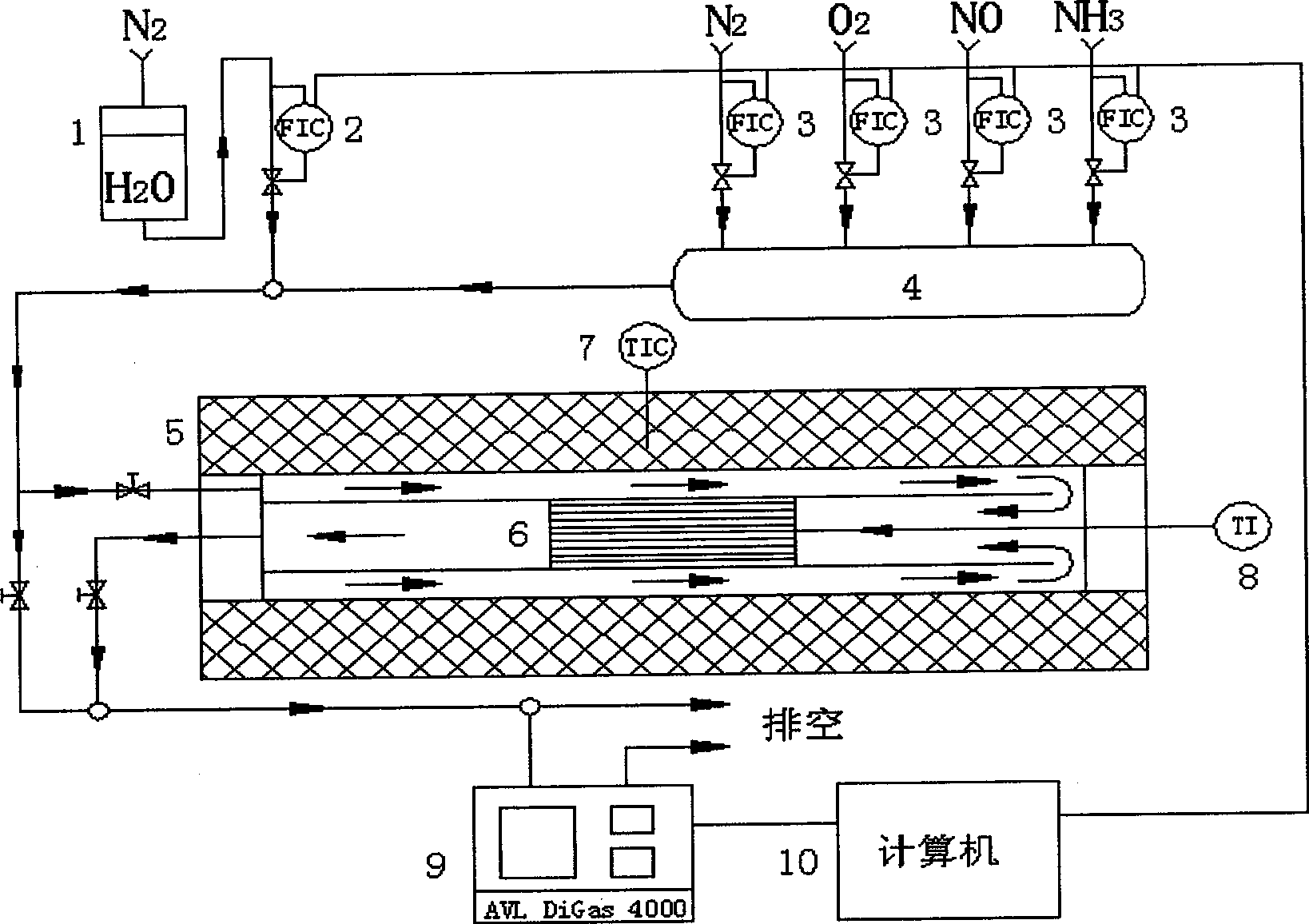

[0025] Preparation of metal honeycomb catalyst E1 for purifying diesel engine exhaust gas: select a metal honeycomb carrier with a main material of 0Cr25Al5, a mesh density of 300 mesh, and an overall size of 50mm×50mm×50mm, and pretreat it in an air atmosphere at 600°C for 3 hours; 16g of 98% copper nitrate and 585g of 98% manganese nitrate are mixed according to different proportions, ammonium bicarbonate solution is continuously added dropwise to the mixed solution until Ph=8, and the precipitation is about one hour. Drying at 623K for 12h, and roasting at 623K to obtain Cu0.01Mn0.5 (623k); 1500g of titanium dioxide, 60g of ammonium metavanate, 30g of cerium nitrate and 300g of copper-manganese composite Cu0.01Mn0.5 (350°C ) to mix, then add 3300g deionized water, stir to obtain slurry, and control the slurry ball mill particle size to D 90 = 30 microns; dip the pretreated metal honeycomb carrier in the slurry, stay for 2 seconds, and lift it out at a speed of 30mm per seco...

Embodiment 2

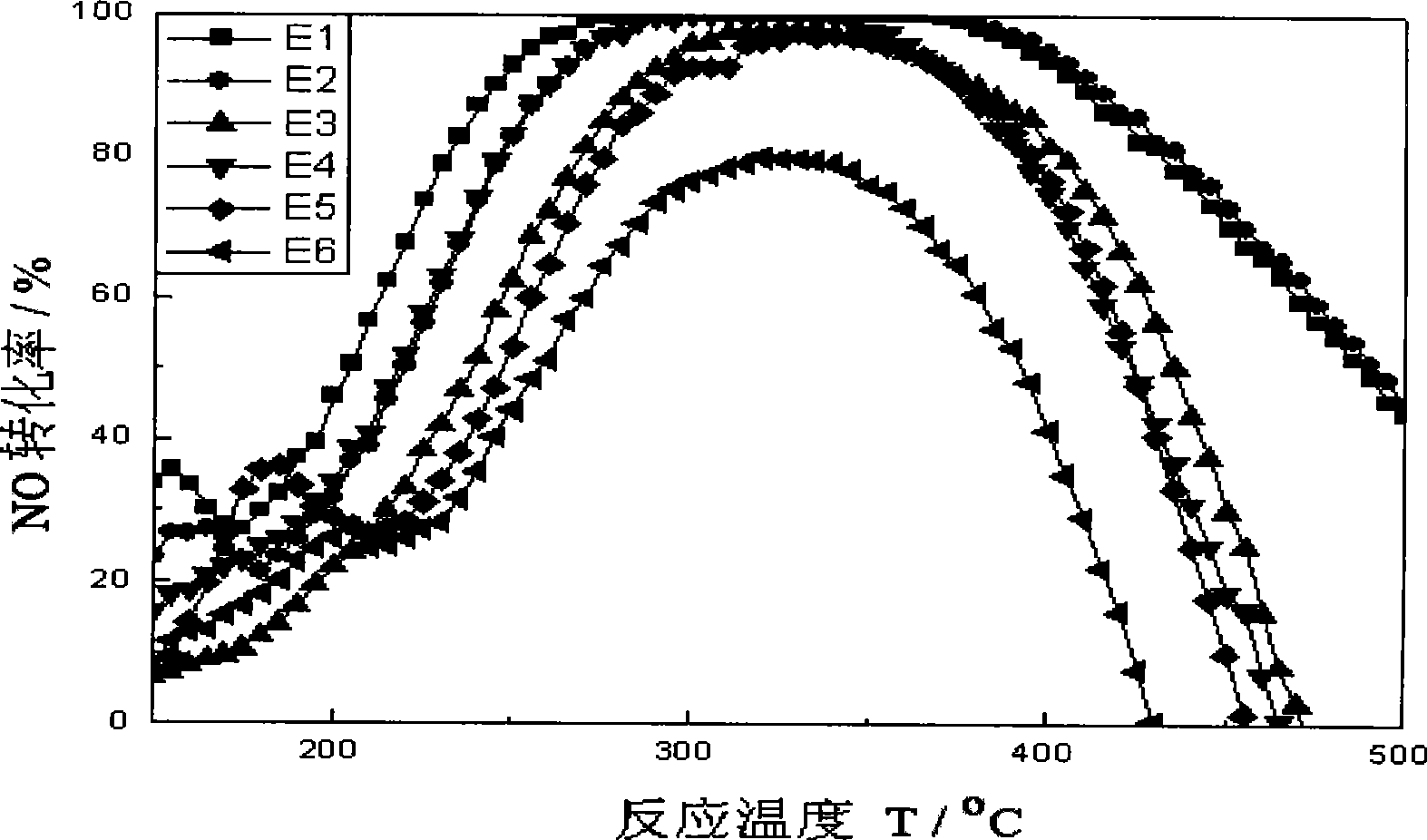

[0028]Preparation of honeycomb catalyst E2 for purifying nitrogen oxides in diesel engine exhaust gas: the specific preparation method is basically the same as that of E1 in this part, the difference is that the copper-manganese composite Cu0.5Mn0.01 (723k) in the raw material contained in the coating is 75g , ammonium metavanadate is 120g, catalyst activity test results see image 3 .

Embodiment 3

[0030] Preparation of metal honeycomb catalyst E3 for purifying diesel engine exhaust gas: the specific preparation method is basically the same as that of E1 in this part, the difference is that the copper-manganese composite Cu0.005Mn0.5 (723k) in the raw materials contained in the coating is 75g, Ammonium is 7.5g, the catalyst activity test result sees image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com