Active gel electrophoresis method for lactalbumin

A gel electrophoresis and whey protein technology, applied in the field of protein electrophoresis, can solve the problems of expensive equipment, sample absorption, and high analysis cost, and achieve the effects of less sample consumption, easy application, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

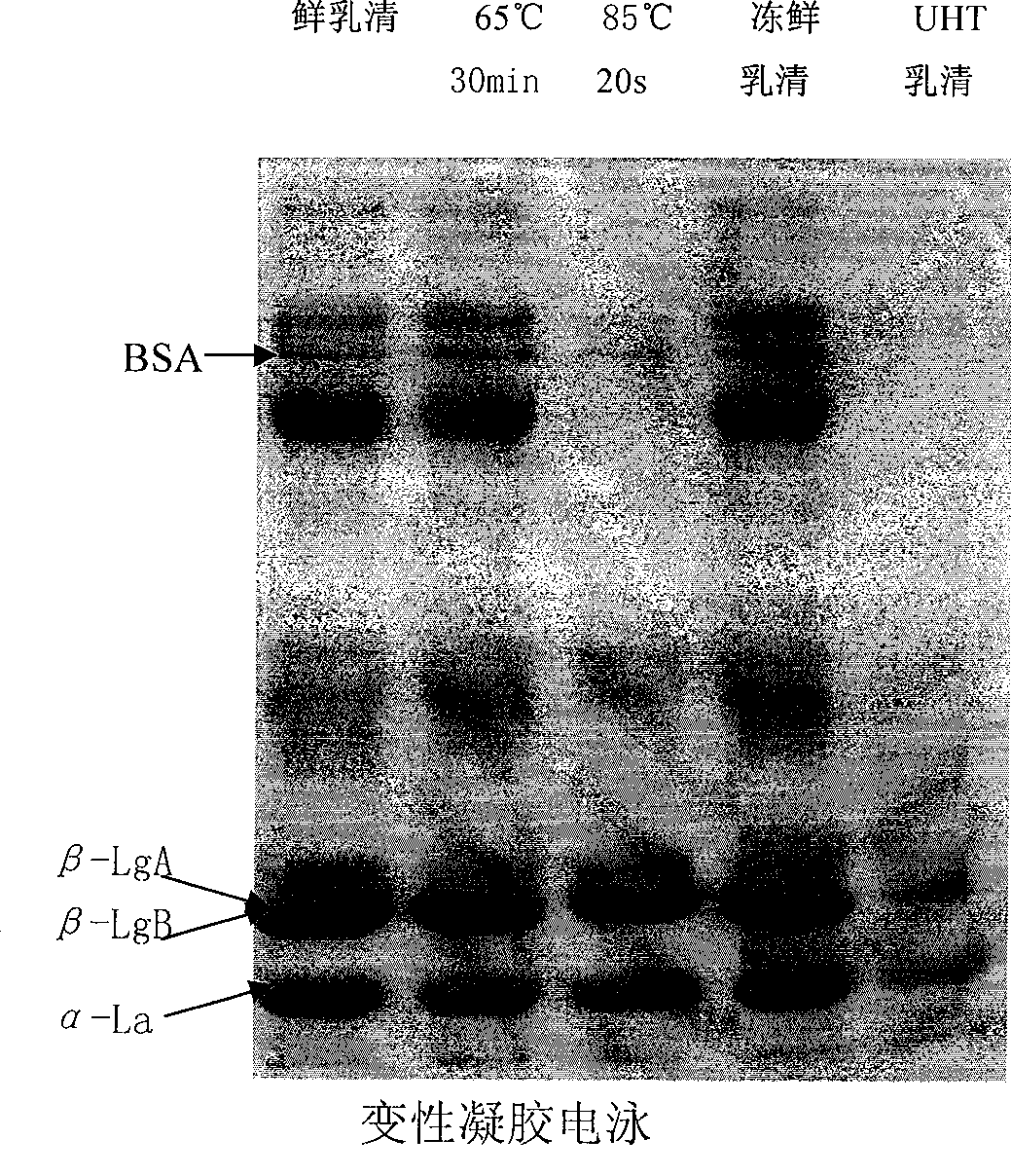

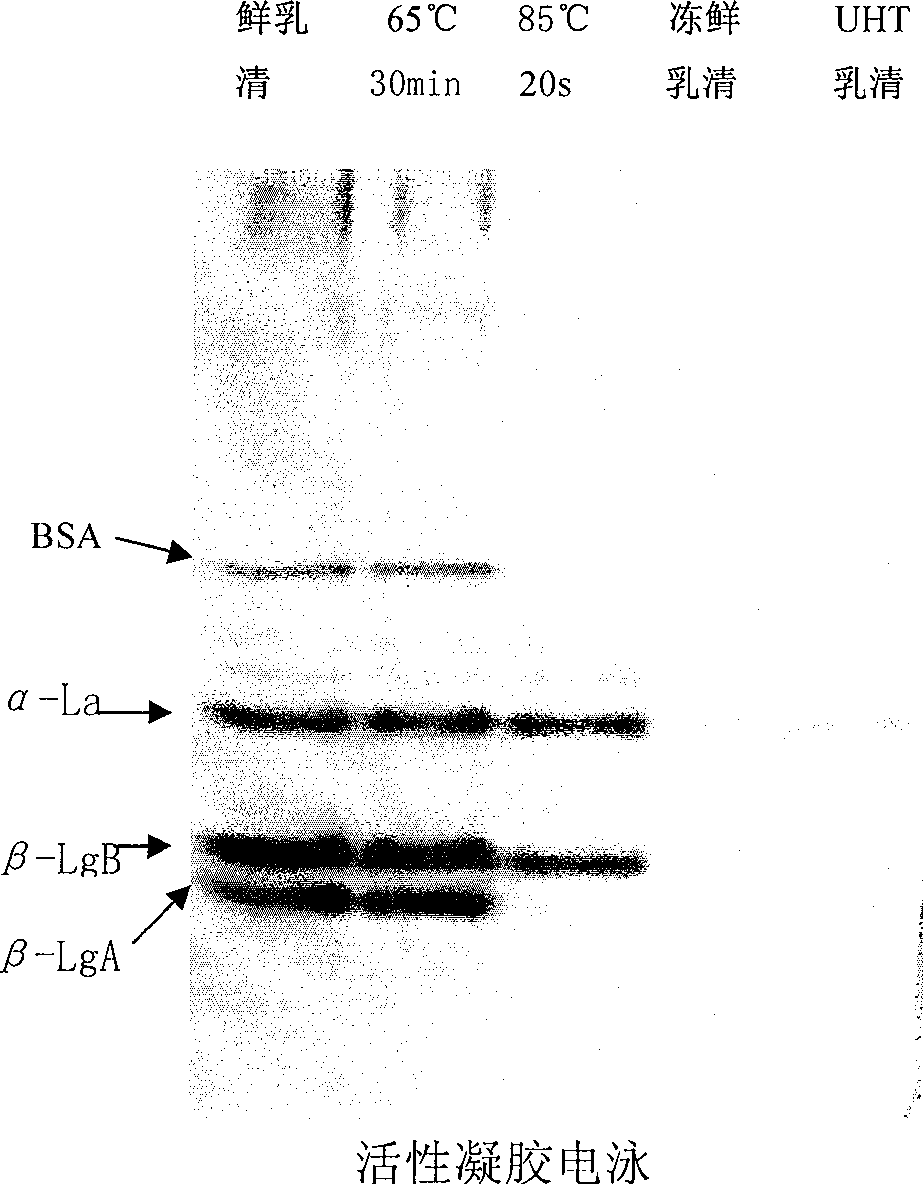

[0061] Example 1 Active Gel Electrophoresis Spectrum and SDS Gel Electrophoresis Electrophoresis Comparison

[0062] Take fresh cow's milk and commercially available UHT fresh milk, centrifuge at 8500g at 4°C for 15min to skim the fat, and divide them evenly into active gel electrophoresis group and SDS gel electrophoresis group. Fresh milk samples from the above two groups (commercially available fresh UHT milk without heat treatment) were heat treated according to the following processes: 1) without heat treatment; 2) 65°C / 30min; 3) 85°C / 20s; 4) frozen at -80°C for 24h, and the heat-treated samples were cooled to room temperature.

[0063] The pH of all samples was adjusted to 4.6 with 6% lactic acid, and after standing for 15 minutes, the casein was removed by centrifugation at 8500g at 4°C for 15 minutes to obtain whey protein, which was stored at -20°C for later use.

[0064] Prepare SDS polyacrylamide gel with 12% separating gel and 4% stacking gel. First prepare 5 mL ...

Embodiment 2

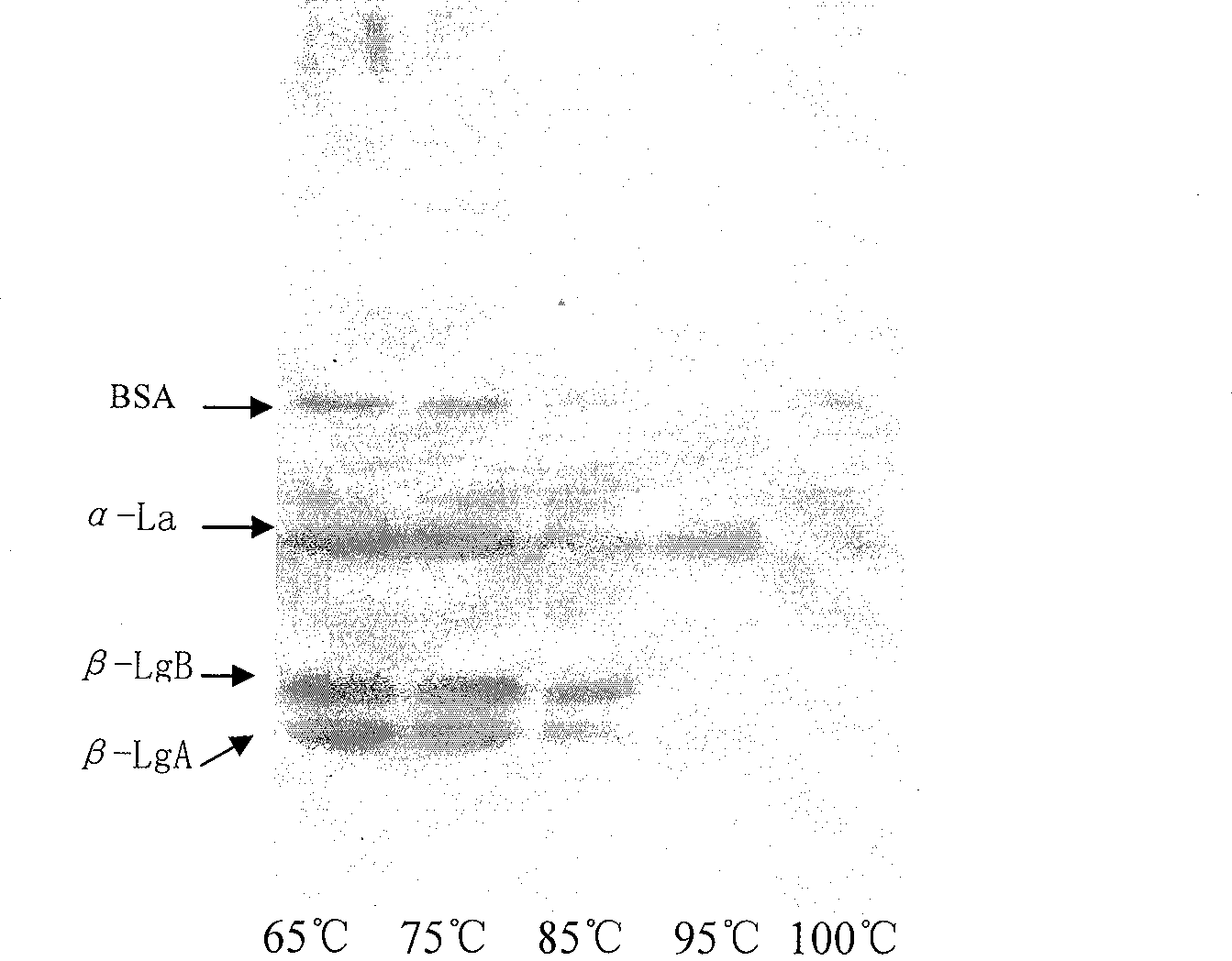

[0073] Example 2 Different heating temperatures, heating times, active gel electrophoresis patterns of heat-treated bovine milk whey protein at pH values

[0074] 1) Active gel electrophoresis patterns of heat-treated bovine whey protein with different heating temperatures and the same heating time:

[0075] Fresh milk was degreased by centrifugation at 8500g at 4°C for 15 minutes, distributed evenly, and heated at 65°C, 75°C, 85°C, 95°C, and 100°C for 10 minutes, and the samples were cooled rapidly after heating. After cooling to room temperature, the pH was adjusted to 4.6 with 2% hydrochloric acid, and after standing for 15 minutes, the casein was removed by centrifugation at 10,000 g at 4°C for 15 minutes, and the obtained supernatant was whey protein. The whey protein was aliquoted and stored at -20°C for later use.

[0076] Prepare an active acrylamide gel with 8% separating gel and 4% stacking gel. The whey protein sample was mixed with 2 times active protein loading ...

Embodiment 3

[0092] Example 3 Identification of Heat-treated Bovine Whey Whey Protein by Active Gel Electrophoresis at Different Heating Temperatures and Different Heating Times

[0093] Fresh milk is degreased by centrifugation at 8500g at 4°C for 15 minutes, evenly distributed and heated at 65°C, 75°C, 85°C, 95°C, and 100°C. Each temperature is divided into different heating time gradients, respectively 5, 10, 20, 30min. The samples were cooled rapidly after heating. After cooling to room temperature, the pH was adjusted to 4.6 with 6% lactic acid, and after standing for 15 minutes, the casein was removed by centrifugation at 8500g at 4°C for 15 minutes, and the obtained supernatant was whey protein. The whey protein was aliquoted and stored at -20°C for later use.

[0094] Prepare active acrylamide gel with 10% separating gel and 4% stacking gel. Mix the whey protein sample with the active protein loading buffer at a ratio of 1:3, centrifuge, and load 12 μL of the sample.

[0095] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com