Gas hydrate generating, sampling and analyzing method and apparatus

A technology for generating gas hydrates and hydrates, which can be used in sampling devices, measuring devices, analysis materials, etc., and can solve the problems of difficulty in sampling and analysis, sampling and analysis of gas components

- Summary

- Abstract

- Description

- Claims

- Application Information

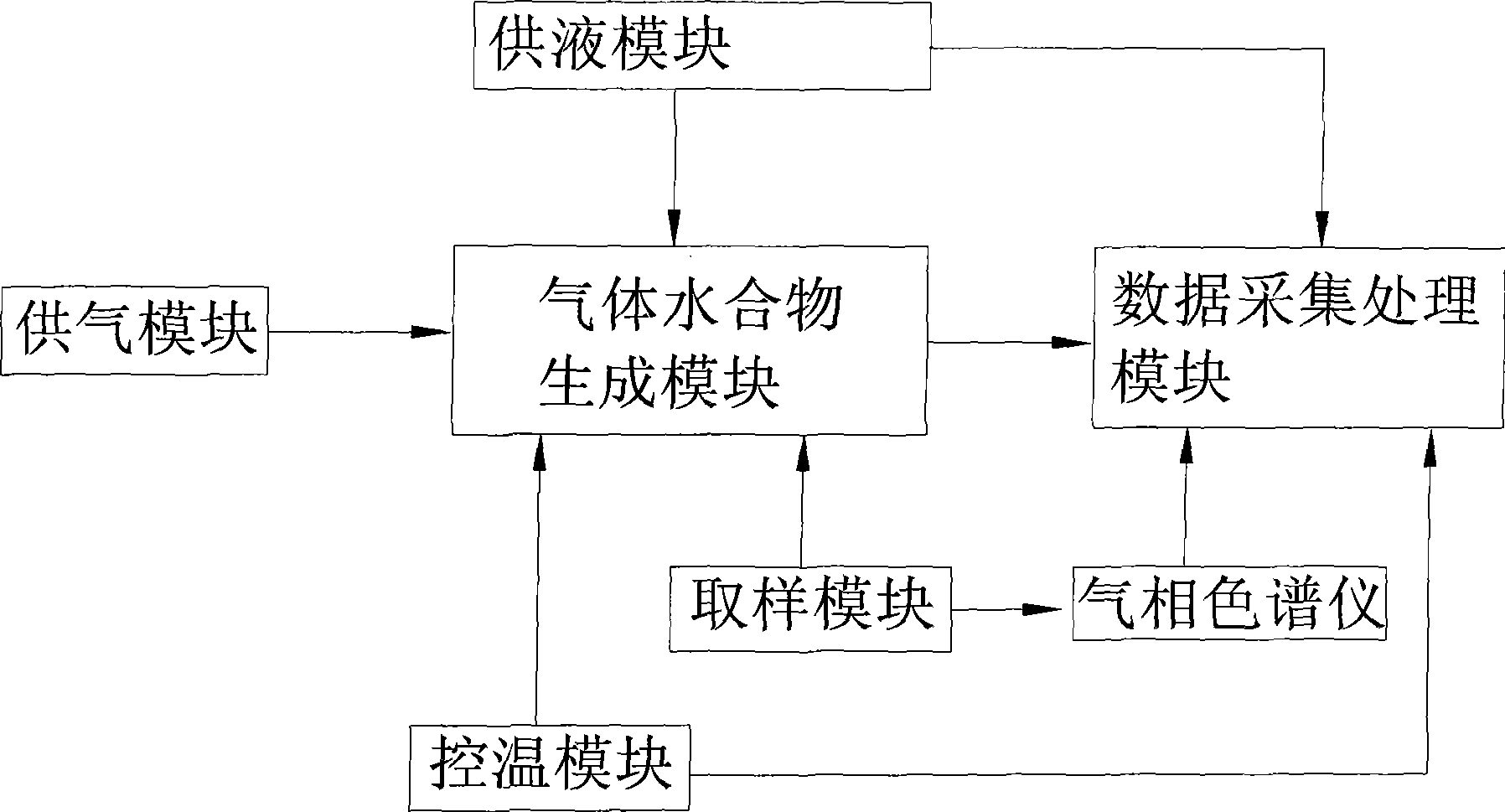

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

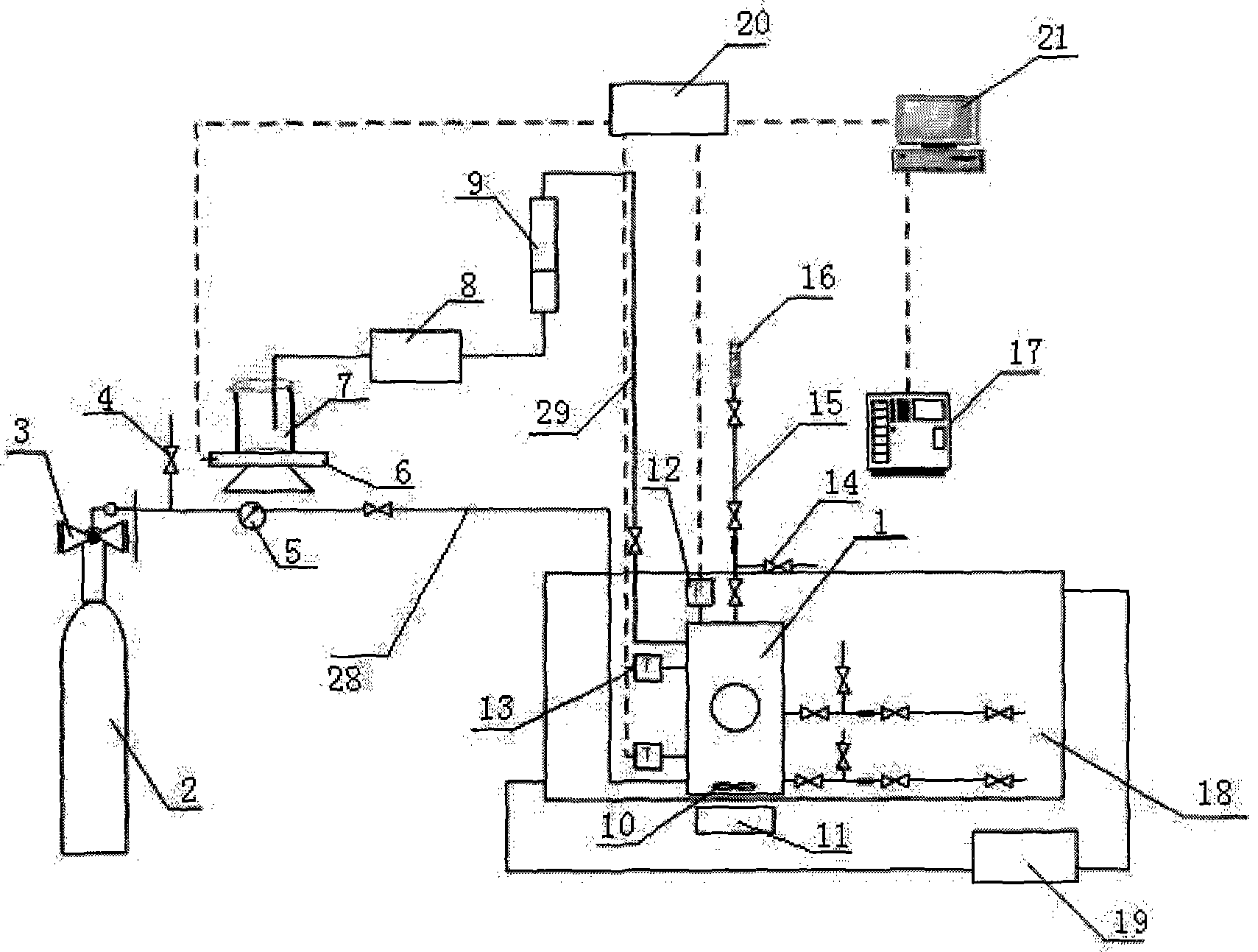

[0070] Mixed gas hydrate phase equilibrium point sampling analysis experiment

[0071] This experiment adopts observation method and temperature search method, and the main experimental steps are as follows:

[0072] 1) During the pure water experiment, the advection pump 8 extracts the deionized water in the container 7 and injects it into the reactor 1, and during the chemical reagent solution experiment, the advection pump 8 extracts the deionized water in the container 7 and injects it into the bottom of the intermediate container 9, and pushes the piston in the intermediate container 9 upward. The chemical reagent solution on the upper part of the piston is injected into the reactor 1;

[0073] 2) Adjust the temperature of the external constant temperature water bath 19 to the experimental temperature, open the internal circulation system of the external constant temperature water bath 19 so that the constant temperature water circulates in the constant temperature water ...

Embodiment 2

[0079] Sampling analysis experiment of mixed gas hydrate formation

[0080] This experiment is mainly about the change of mixed gas components during the formation of multi-component mixed gas hydrates. The main experimental steps are as follows:

[0081] (1) Inject the reaction liquid into the reaction kettle 1, vacuumize, control the temperature of the water bath to reach the experimental set temperature, inject multi-component mixed gas, and make the pressure in the reaction kettle 1 higher than the equilibrium pressure of the mixed gas hydrate formation phase at this temperature , the mixed gas reacts with the liquid in the reactor 1 to generate a large amount of mixed gas hydrate;

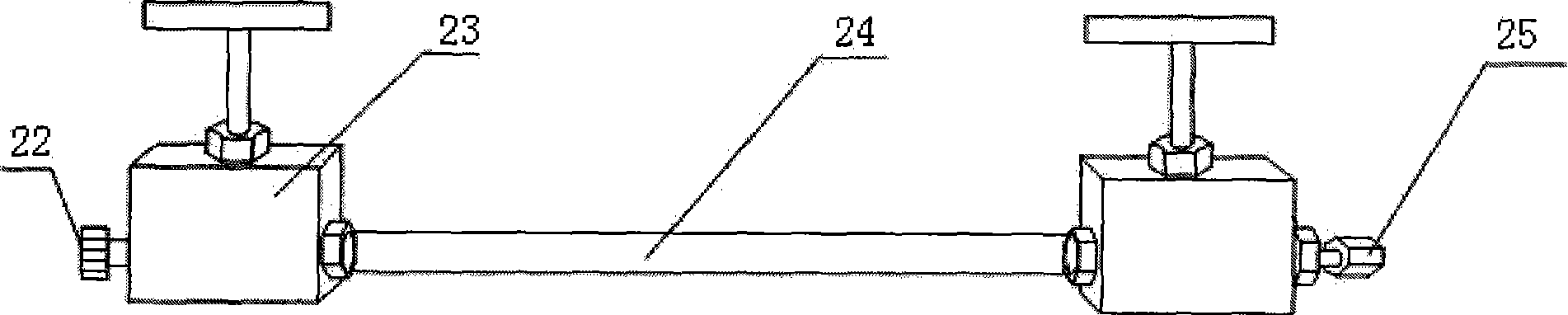

[0082] (2) During the formation process of mixed gas hydrate, during the gas dissolution process, a small amount of gas phase and liquid phase samples were respectively drawn to the gas chromatograph 17 to analyze the components when the pressure was fast at the beginning. When it continues t...

Embodiment 3

[0085] Hydrate Gas Separation Experiment

[0086] (1) Inject reaction liquid in reactor 1, can measure and calculate and obtain injection liquid volume V by electronic balance 6 l , given the volume V of the reactor 1, the gas phase volume V can be obtained gas = V - V l , the reaction kettle 1 is evacuated, and the temperature of the water bath is controlled to reach the experimental set temperature T;

[0087] (2) Configure component x according to experimental requirements A,0 The separation gas (A, B), this gas is first extracted by the gas-tight syringe 16 and injected into the gas chromatograph 17 to analyze whether the component is x A,0 , and then inject the gas into the reactor 1, so that the pressure in the reactor 1 is higher than the equilibrium pressure P of the separated gas hydrate formation phase at this temperature 0 , can be calculated by the formula PV=ZnRT(1) to get the injected separation gas n 0 mol, the separated gas reacts with the liquid in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com