High-speed multi-beam parallel laser direct-writing device

A laser direct writing and multi-beam technology, which is used in photolithography process exposure devices, laser welding equipment, microlithography exposure equipment, etc. and other problems, to achieve the effect of shortening writing time, improving system reliability, and reducing temperature drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

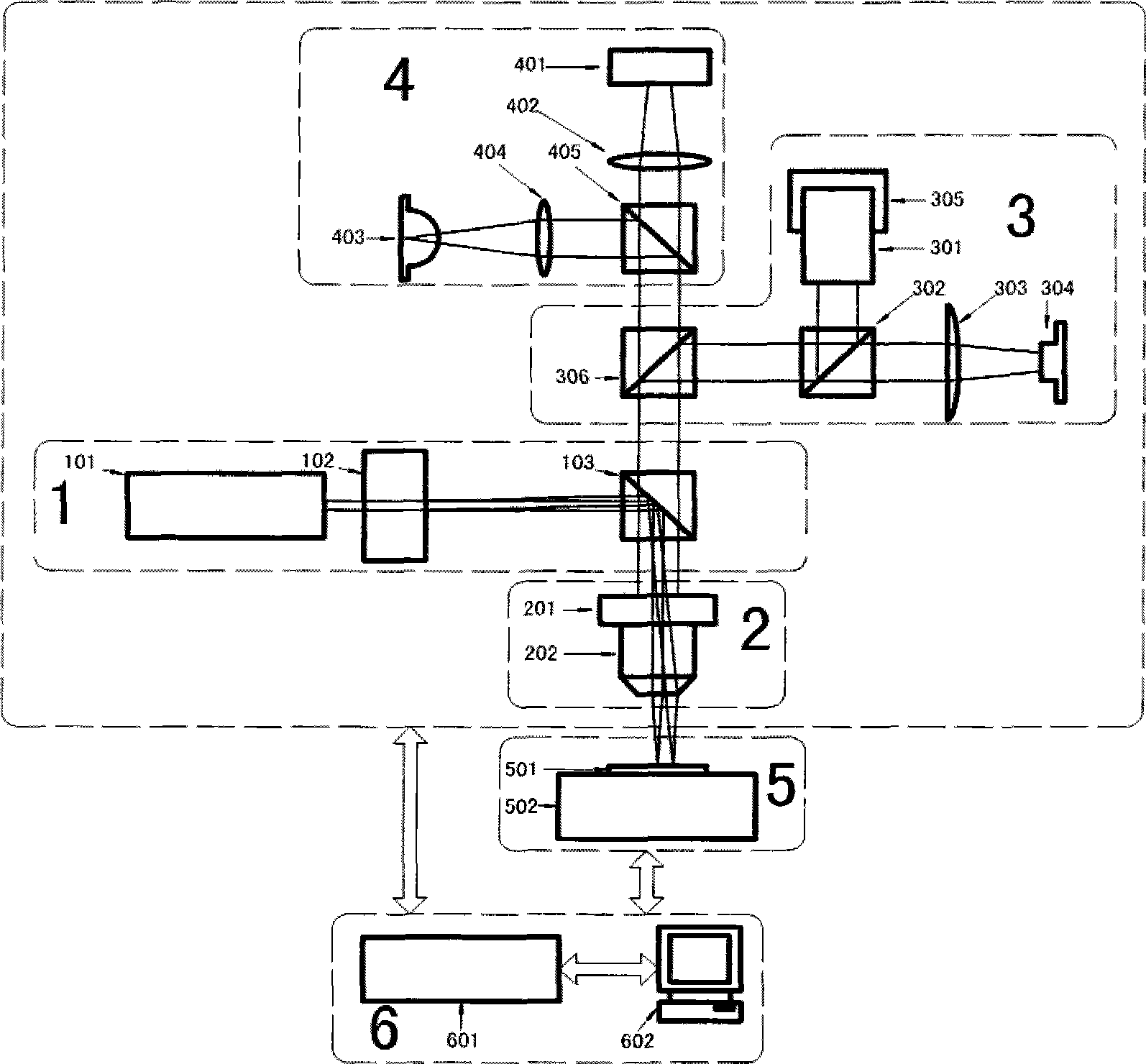

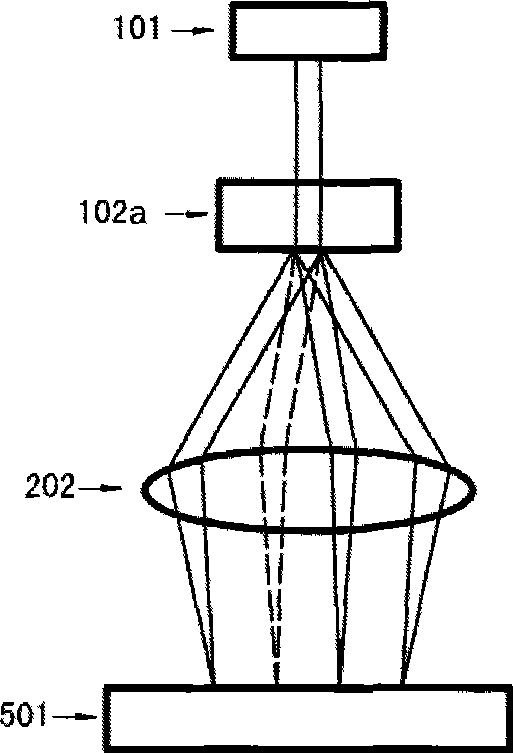

[0057] see first figure 1 , figure 1 It is a schematic diagram of the overall structure of the first embodiment of the high-speed multi-beam parallel laser direct writing device of the present invention, figure 2 It is the basic principle diagram of multi-beam writing in this embodiment. The high-speed multi-beam parallel laser direct writing device of the present invention is composed of six modules: a writing light source modulation module 1, a writing optical head 2, a defocus detection module 3, an illumination and monitoring module 4, a sample displacement table 5, and a main control module 6.

[0058] The writing light source modulation module 1 includes a laser 101 , an acousto-optic modulator 102 , and a spectroscopic beam splitter 103 . The laser 101 is a gas, solid or semiconductor laser, preferably a semiconductor laser. The spectral beam splitter 102 has high reflectivity for the laser light emitted by the laser 101 and high transmittance for other wavelength l...

no. 2 example

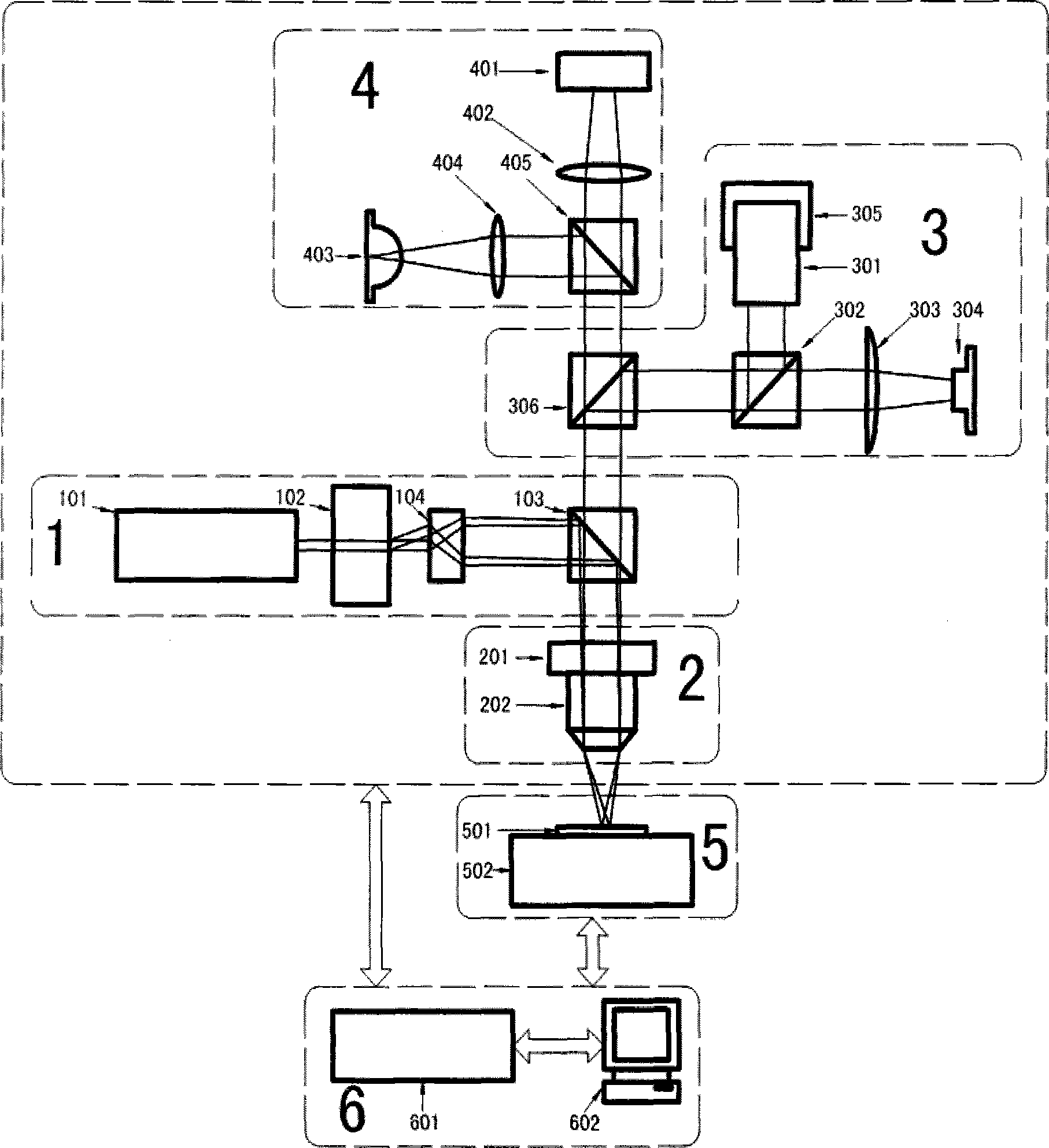

[0086] The overall structure schematic diagram of the second embodiment is as image 3 As shown, its working principle is as follows Figure 4 shown. Compared with the first embodiment, the feature of this embodiment is that a bi-telecentric lens group 104 is added between the acousto-optic modulator 102 and the spectral beamsplitter 103, and the function is to carry out the light beam emitted by the acousto-optic modulator The beam is expanded and collected at the entrance pupil of the writing objective lens 202 , and the light beam fills the entrance pupil of the writing objective lens 202 , thereby having a smaller converging spot and a smaller size of the writing spot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com