Adsorbing substance for absorbing heavy metal ion and preparation method thereof

A technology for adsorbing heavy metals and adsorbents, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as difficult large-scale industrial applications, weak adsorption capacity, strong odor, etc. Adjust, improve regeneration ability, increase the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

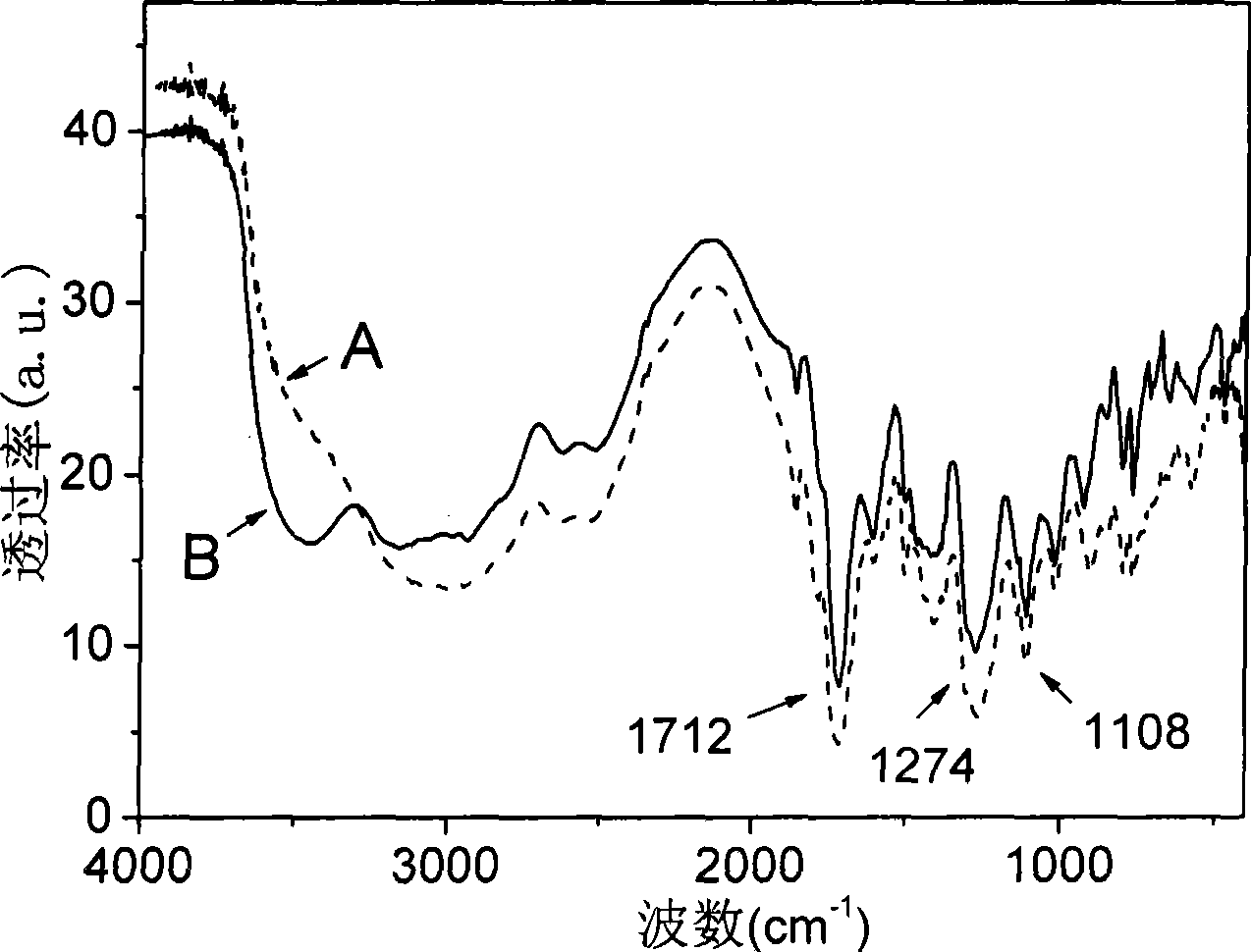

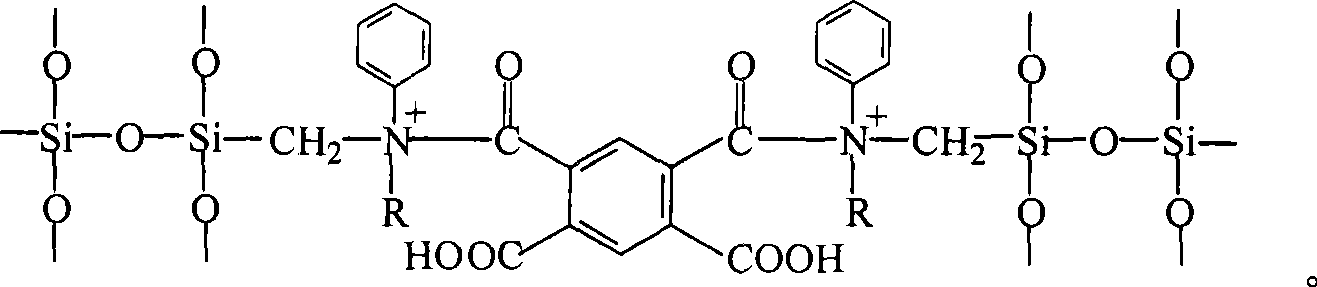

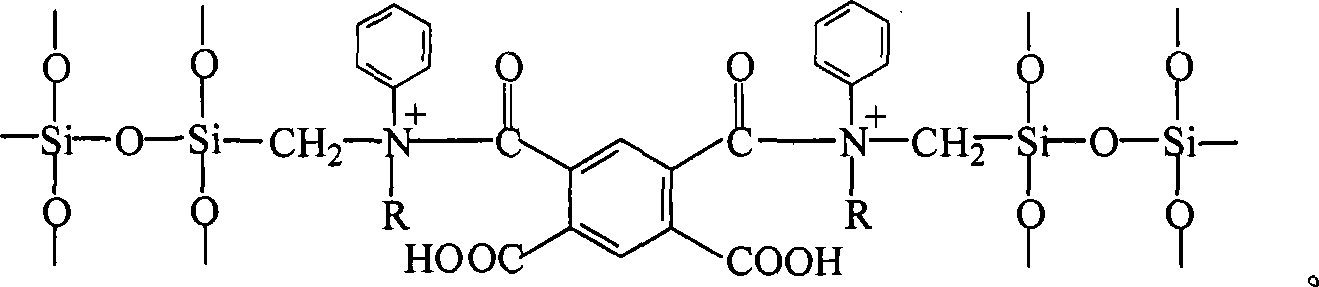

[0030] Example 1. Preparation of an adsorbent for adsorbing heavy metal ions with reactant ratio pyromellitic anhydride (PMDA):anilinomethyltriethoxysilane (ND-42):bromoethane=4:1:6

[0031] In a 250ml three-necked flask equipped with a stirrer, air or nitrogen was introduced first, then 15ml of N,N-dimethylformamide (DMF) was added, and 10.12g of pyromellitic anhydride (PMDA) was added under the condition of air or nitrogen. ); make it dissolve under constant stirring, then add dropwise 2.5ml mass percent composition and be 95% anilinomethyltriethoxysilane (ND-42) solution to carry out epoxy ring-opening reaction, control the mol ratio of reactant For pyromellitic anhydride (PMDA): anilinomethyltriethoxysilane (ND-42) = 4:1 (that is, keep the excess of PMDA). In the process of adding the silane coupling agent, it can be found that the two react violently and release a lot of heat, indicating that the reaction is in progress, and pyromellitic anhydride dissolves quickly. When...

Embodiment 2

[0037] Example 2. Preparation of an adsorbent film for adsorbing heavy metal ions with reactant ratio pyromellitic anhydride (PMDA):anilinomethyltriethoxysilane (ND-42):bromoethane=4:1:6 piece

[0038] Using the same device and operating steps as in Example 1, under the temperature condition of -78°C, dissolve 10g of the raw material with 20ml of solvent N, N-dimethylformamide (DMF), and then carry out the amination reaction at a temperature of 30°C. Dissolve the product of the amination reaction with DMF solvent, and then use the solution in Al 2 o 3 Dip the coating film on the ceramic substrate until the membrane is obtained, and dry the membrane by infrared rays for 12 hours in an environment at 200°C and a relative humidity of 70% to obtain a hybrid membrane. The membrane of the hybrid membrane can be used for adsorption Adsorbent for heavy metal ions. In order to ensure the completeness of the ring-opening reaction and improve the ability of the adsorbent to absorb hea...

Embodiment 3

[0042] Example 3. Preparation of pyromellitic anhydride (PMDA): anilinomethyltriethoxysilane (ND-42): catalyst: ethyl bromide = 4:1:0.001:6 for the adsorption of heavy metal ions in the ratio of reactants Adsorbent

[0043] Using the same device and operation steps as in Example 1, at a temperature of 60°C, in the hybrid precursor solution prepared in Example 1, the molar ratio is silane coupling agent: water: catalyst = 1:0.01: Add deionized water and catalyst triethylamine at 0.001, stir until a uniform solution is obtained, and then carry out amination reaction on the solution. During the amination reaction, add haloalkane bromide ethyl bromide to the above solution at a molar ratio of 6 times the silane coupling agent. Alkanes, so that it contains basic and acidic groups, the resulting substance after the reaction is washed with deionized water or ethanol, and dried at 150 ° C for 12 hours to obtain an adsorbent that can be used to adsorb heavy metal ions. It contains carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com