Intermediate frequency induction heating type hot double-roll reversing roller and rolling method

A technology of induction heating and induction heater, which is applied in metal rolling, roll speed control, metal rolling, etc., can solve problems such as difficulties, low production efficiency, and low yield, and achieve uniform temperature, high production efficiency, The effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

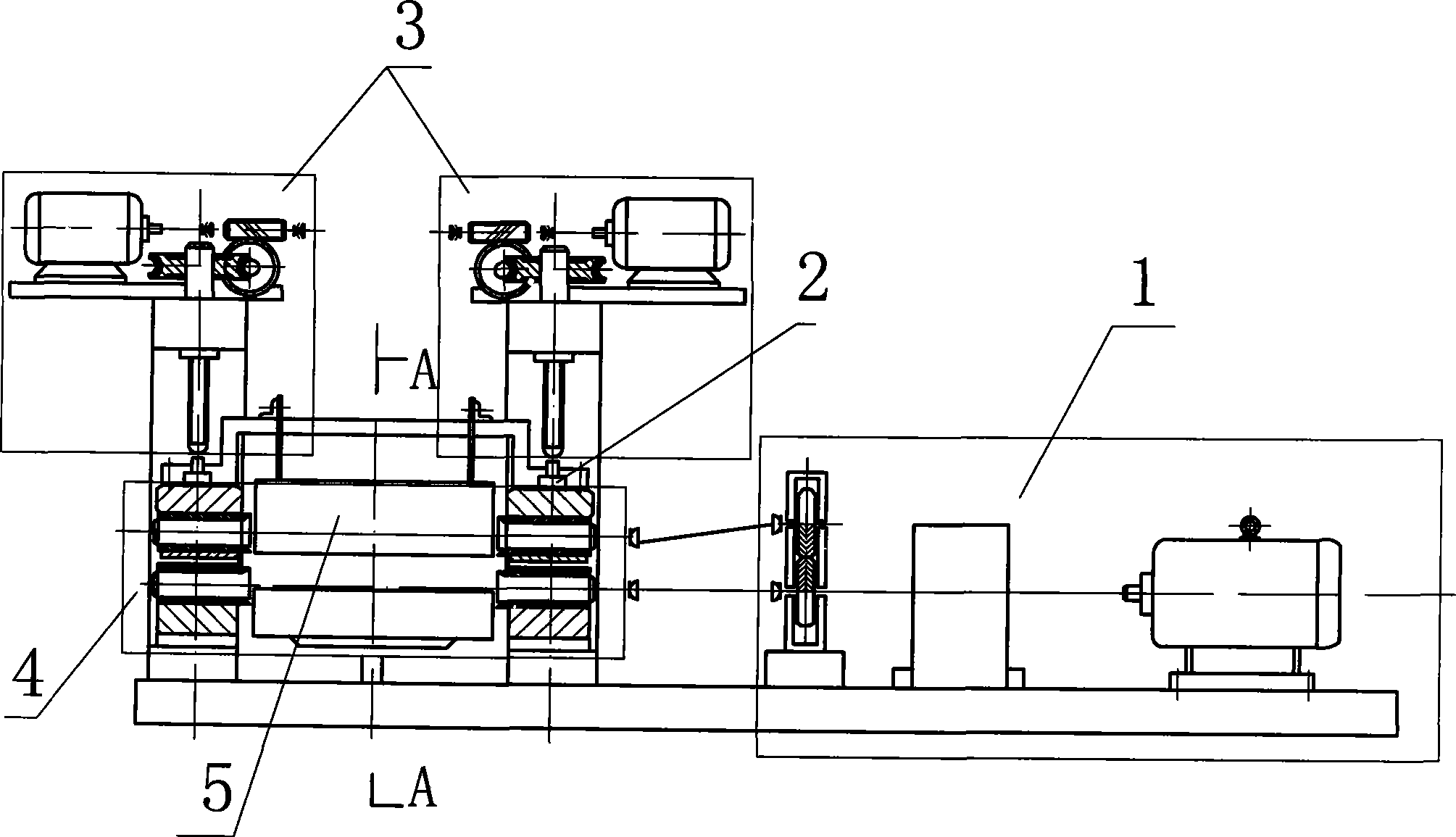

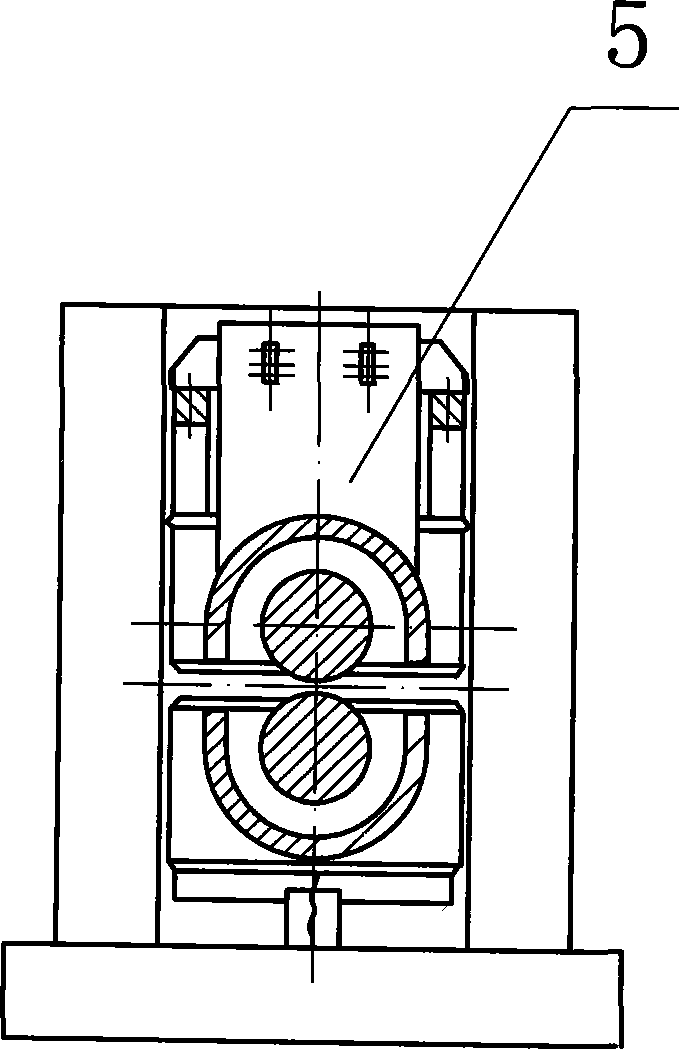

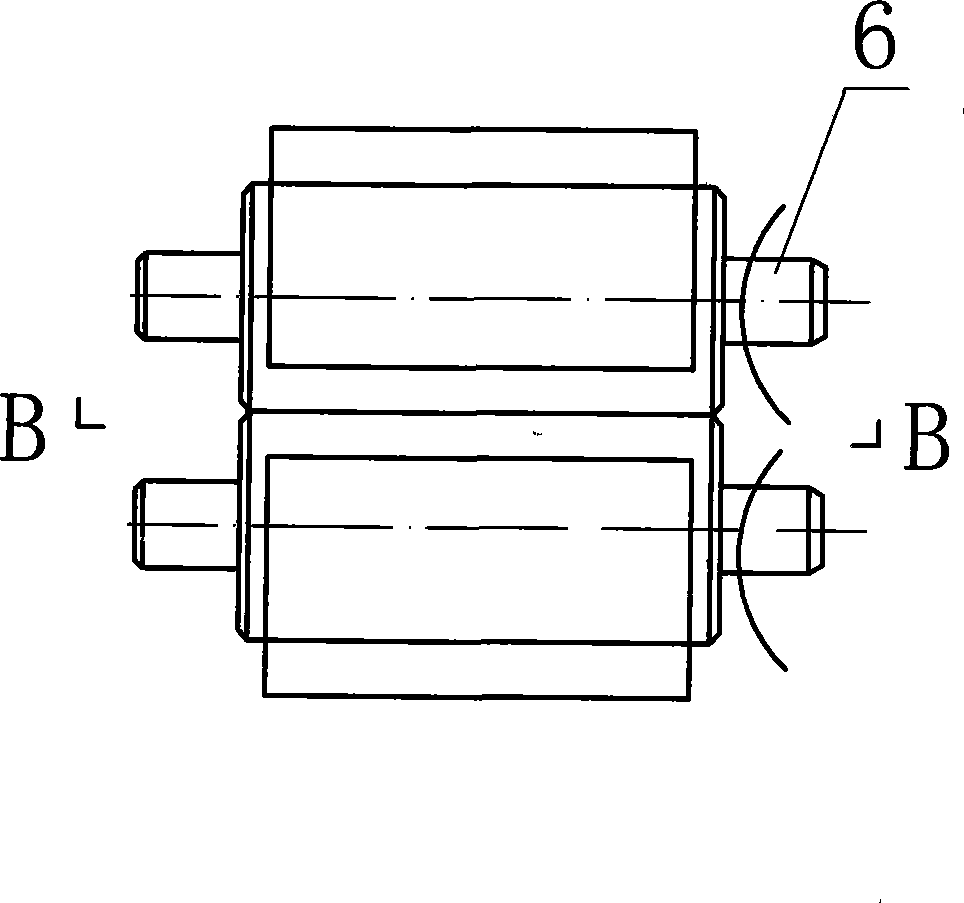

[0021] The medium-frequency induction heating hot double-roll reversible rolling mill includes: a reversible rolling mill body, the rolling mill body adopts an open induction heater, and the load coils are arranged in the axial direction of the rolls, and the bearings of the rolling mill body are provided with cooling channels for circulating water Cooling, the roll heating system of the rolling mill body adopts a crystal gate type intermediate frequency induction heating equipment, and the surface temperature of the roll adopts a far-infrared sensor.

[0022] The medium-frequency induction heating type hot double-roll reversible rolling mill has a roll diameter of Φ400mm-Φ600mm, a roll length of 400mm-1000mm, and a far-infrared sensor is used to perform closed-loop automatic control of the roll surface temperature, and the control temperature range is 300°C to 1000mm. 450°C, the power of the induction heater is 75kw~150kw, the roll bearing is cooled by cooling water, and the w...

Embodiment 2

[0025] The intermediate frequency induction heating hot double-roll reversible rolling mill adopts the crystal gate type intermediate frequency induction heating device to heat the two rolls of the reversible rolling mill. The induction heating load coils are arranged in the axial direction of the rolls. Can be selected within the range of 400mm ~ 1000mm. The far-infrared sensor is used to automatically control the surface temperature of the roll in a closed loop, and the temperature range is 300°C to 450°C.

[0026] The power of the induction heater is selected within the range of 75kw ~ 150kw, the roll bearing is cooled by cooling water, and the working temperature of the control bearing cannot be greater than 60°C. The roll material should be tool and die steel whose quenching temperature must be between 550°C and 560°C after quenching. After quenching, the roll must be treated at a low temperature of -60°C to eliminate residual austenite. The hardness after fire must be g...

Embodiment 3

[0029] Medium frequency induction heating type - key technical parameters of hot twin-roll reversing rolling mill manufacturing technology:

[0030] 1. The roll size of the two-roll reversing mill is Φ400mm×800mm, and the roll length is 400mm~1000mm.

[0031] 2. The maximum rolling force of the double-roller reversing mill is 4500KN~6000KN, and the rolling speed is 10~60m / min. The motor power is 500kw~750kw.

[0032] 3. The thyristor type intermediate frequency induction heating device, the load coil of the induction heater is arranged according to the length direction of the roll, see the attached figure 1 , Induction heater power 75kw ~ 150kw.

[0033] 4. The material of the roll is W6Mo5Cr4V2. After quenching, it is cold treated at -60°C, and the tempering temperature is 560°C for three times. After tempering, the surface hardness of the roll is above HRC56.

[0034] 5. The working temperature of the roll is controlled between 300°C and 450°C, and the far-infrared sensor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com