Unsaturated polyester resin for moulding compound and preparation thereof

A polyester resin, unsaturated technology, applied in the field of polymer chemical industry, can solve the problems of limited use, not too wide application surface, long reaction time, etc., to achieve improved corrosion resistance and aging resistance, smoothness, and brittleness. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare a kind of unsaturated polyester resin for molding compound according to following raw material formula and preparation method, formula is:

[0032] Propylene glycol 230g

[0033] Dipropylene glycol 83g

[0034] Methylpropanediol 22g

[0035] Phthalic anhydride 90g

[0036] Maleic anhydride 310g

[0037] Styrene 320g

[0038] Preparation method: (1) Add propylene glycol and phthalic anhydride into a 1000ml four-necked bottle;

[0039] (2) Stir and heat up to effluent, control the temperature of the distillation head not to exceed 103°C, and the reaction temperature not to exceed 190°C until the acid value is 30-40mgKOH / g;

[0040] (3) After cooling down to 160°C, add dipropylene glycol, methylpropanediol and maleic anhydride;

[0041] (4) Continue to heat up, control the distillation head temperature below 103°C, and the reaction temperature below 200°C until the acid value of the reactant is less than 30mgKOH / g, and the viscosity of the polyester is at 650...

Embodiment 2

[0045] The unsaturated polyester resin for molding compound is prepared by the method of embodiment 1, and the specific raw material formula is:

[0046] Propylene glycol 244g

[0047] Dipropylene glycol 74g

[0048] Methylpropanediol 29g

[0049] Phthalic anhydride 88g

[0050] Maleic anhydride 320g

[0051] Styrene 340g

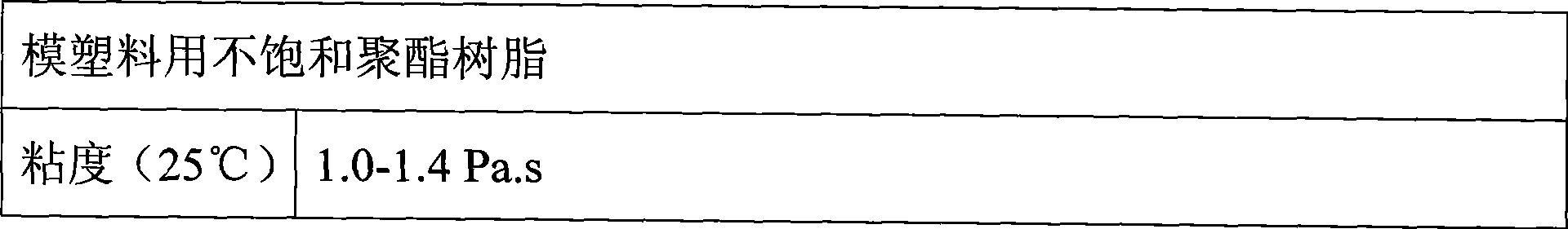

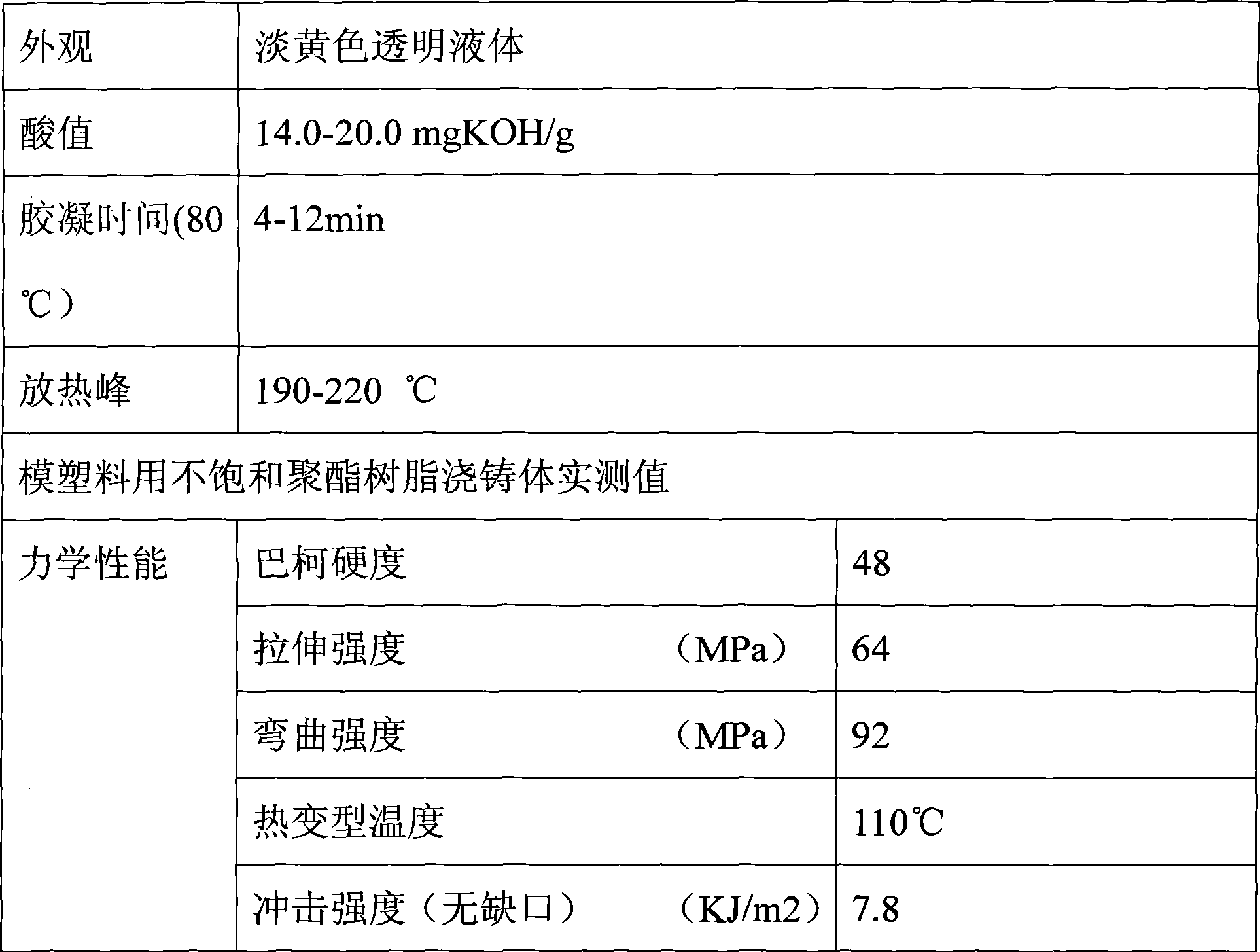

[0052] The unsaturated resin performance detection data that the embodiment of the present invention 1,2 makes is as following table:

[0053]

[0054]

Embodiment 3

[0056] The unsaturated polyester resin for molding compound is prepared by the method of embodiment 1, and the specific raw material formula is:

[0057] Propylene glycol 235g

[0058] Dipropylene glycol 82g

[0059] Methylpropanediol 24g

[0060] Phthalic anhydride 90g

[0061] Maleic anhydride 312g

[0062] Styrene 324g

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com