Method for measuring red phosphorus content in electronic product by photometry

An electronic product and content technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve problems such as harm to human health, and achieve reliable methods, convenient methods, and convenient methods. effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

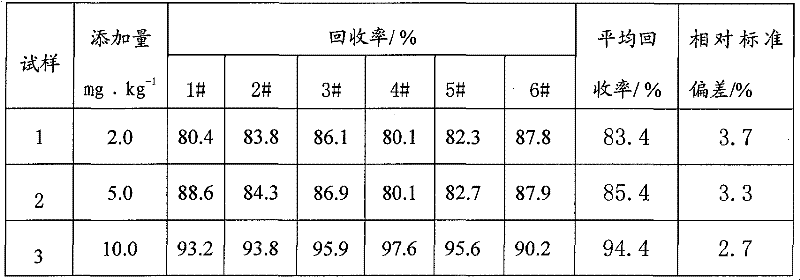

[0011] Example 1: Detection of precision and recovery rate of red phosphorus content in plastics

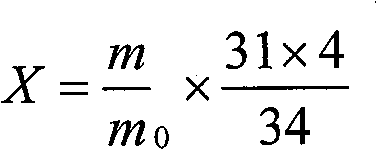

[0012] Weigh 10 g of the sample pulverized by a freeze pulverizer, accurately weigh it to 0.0001 g, put it into a gas generating bottle, add it to 100 mL of 40% sodium hydroxide solution preheated to 50 ° C, connect a nitrogen blowing device, and Introduce the generated gas into 10mL of acidic potassium permanganate solution with a concentration of 0.05mol / L, blow with nitrogen continuously for ten minutes, then transfer the absorption liquid to a 25mL stoppered colorimetric tube, add saturated sodium sulfite solution dropwise until the color of potassium permanganate fades After exhaustion, add 2 more drops, add 0.3mL sulfuric acid solution, 0.2mL ammonium molybdate solution, and mix well; add 1 drop of stannous chloride solution, set the volume to the mark, shake well; heat in a 50°C water bath for 10 minutes, Take it out, cool it to room temperature, measure the absorbance at ...

Embodiment 2

[0024] Embodiment 2: detection of precision and recovery rate of red phosphorus content in resin:

[0025] Weigh 10 g of the sample pulverized by the freeze pulverizer, and accurately weigh to 0.0001 g, put the processed sample into a gas generating bottle, add 100 mL of 40% sodium hydroxide solution heated to 50 °C in advance, connect Nitrogen blowing device, introduce the generated gas into 10mL acidic potassium permanganate solution with a concentration of 0.05mol / L, blow nitrogen continuously for ten minutes, then transfer the absorption liquid to a 25mL stoppered colorimetric tube, add saturated sodium sulfite solution dropwise to the permanganese After the color of potassium acid fades, add 2 more drops, add 0.3mL sulfuric acid solution, 0.2mL ammonium molybdate solution, and mix well; add 1 drop of stannous chloride solution, set the volume to the mark, shake well; put it in a water bath at 50°C Heat for 10 minutes, take it out, cool to room temperature, measure the abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com