Fast appraisement method for waste paper-pulp gummy substance control effect

A sticky matter control and evaluation method technology, applied in the field of rapid evaluation of waste paper pulp sticky matter control effect, can solve the problems of poor repeatability, complicated operation, expensive equipment, etc., and achieve the effect of fast measurement speed and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

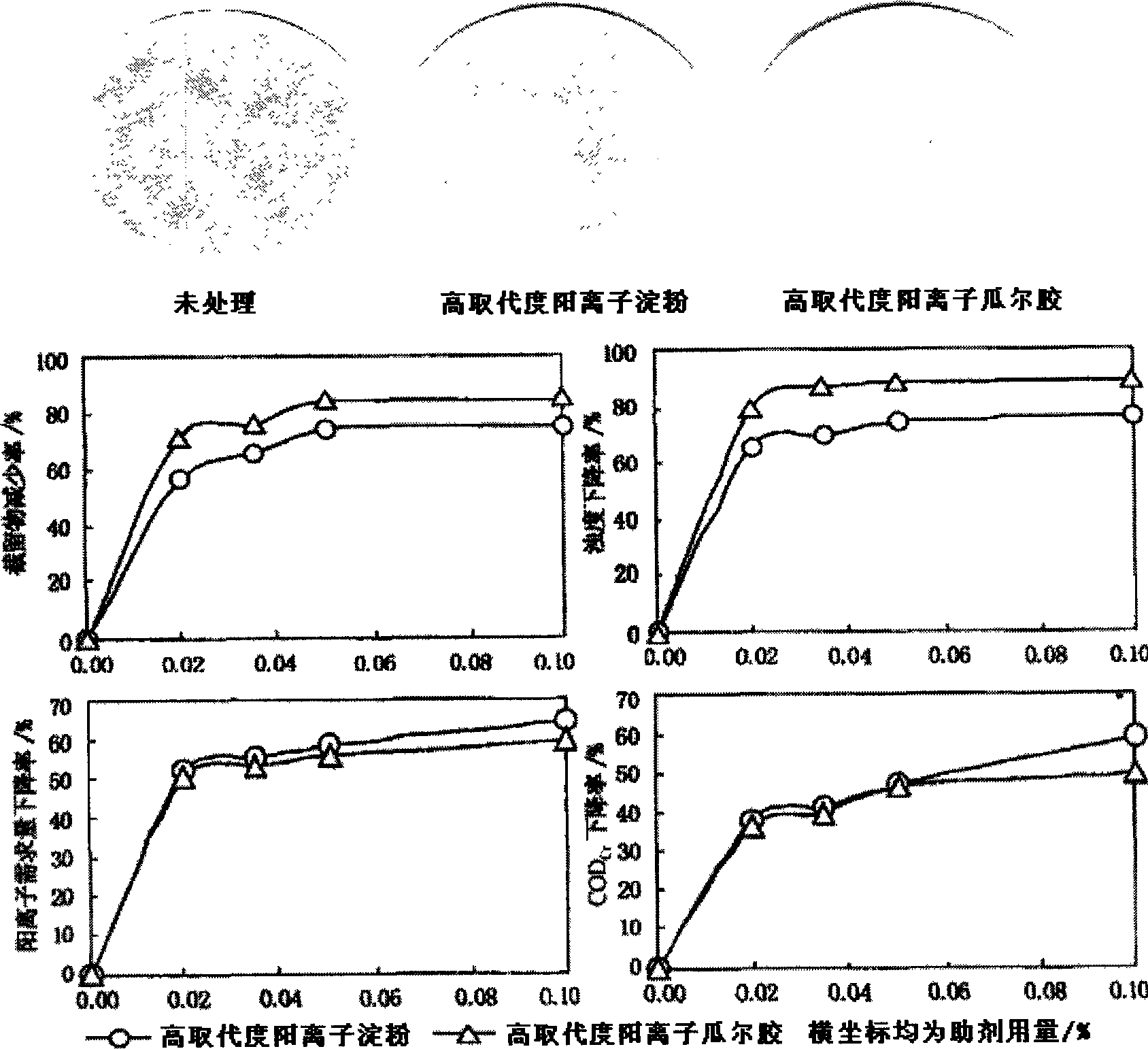

[0020] Highly substituted cationic starch and high substituted cationic guar gum control waste paper deinking and bleaching pulp stickies

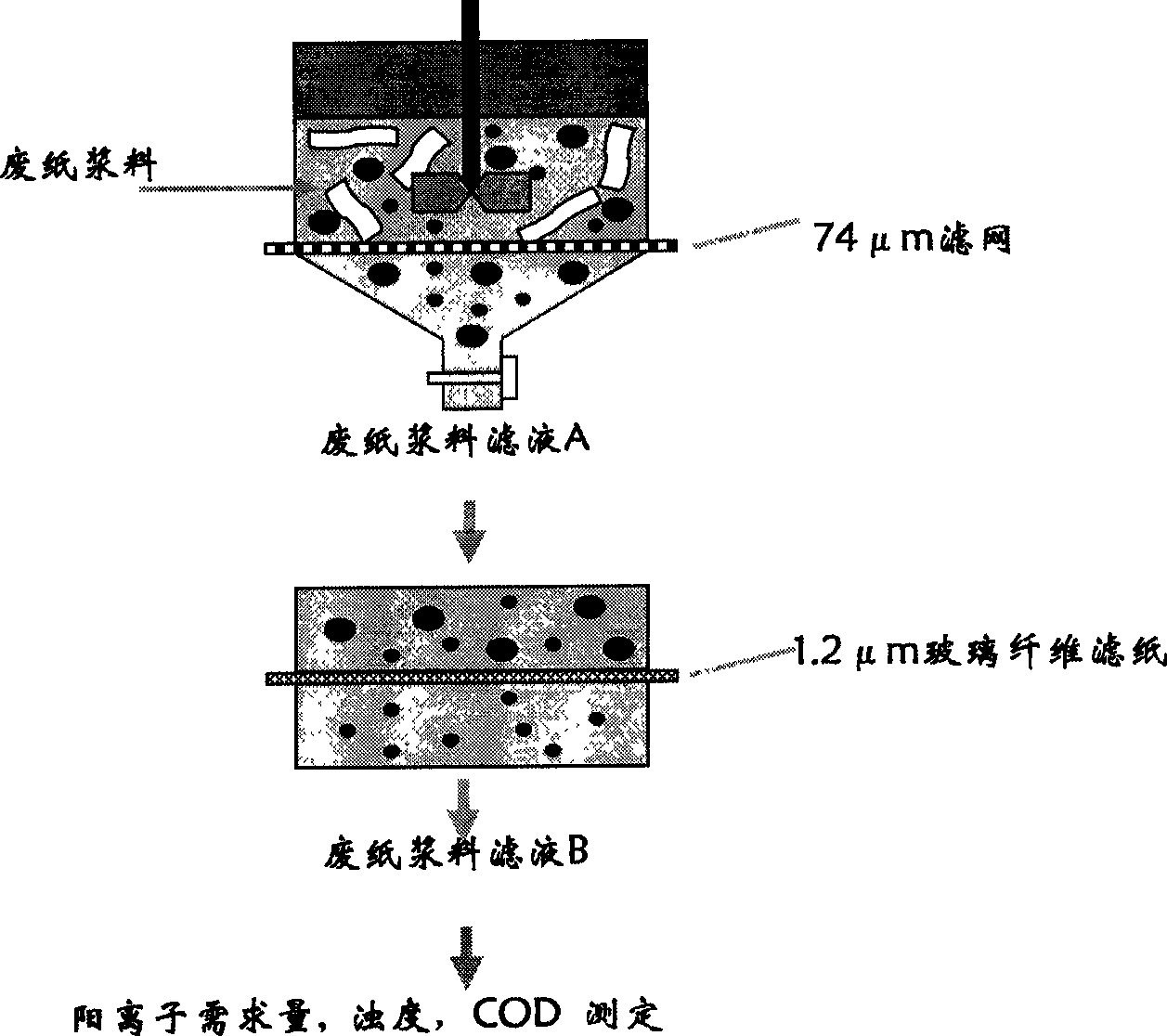

[0021] The waste paper pulp used in the experiment was taken from the pulp storage tank of a newsprint production line in a paper mill. The waste paper pulp had gone through processes such as pulping, flotation deinking, hydrogen peroxide bleaching, and heat dispersion, but no wet-end additives had been added. Predetermine its pulp concentration (generally 3%-5%), weigh 100g of this waste paper pulp, place it in a beaker, add high substitution cationic starch and high substitution cationic guar gum with substitution degrees of 0.94 and 0.30 respectively, After stirring for 3 minutes, dilute the waste paper pulp sample to 500g with distilled water, and then filter with a 200 mesh (74 μm) filter screen. The filtrate A is collected in a beaker, and then filtered with a solvent filter equipped with a glass fiber microfiltration membrane (microf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com