Microwave assisted method for synthesizing polysaccharide monohydrate selenium dioxide ester

A technology for synthesizing selenite and polysaccharide, which is applied in the field of microwave-assisted synthesis and achieves the effects of short reaction time, controllable reaction conditions and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

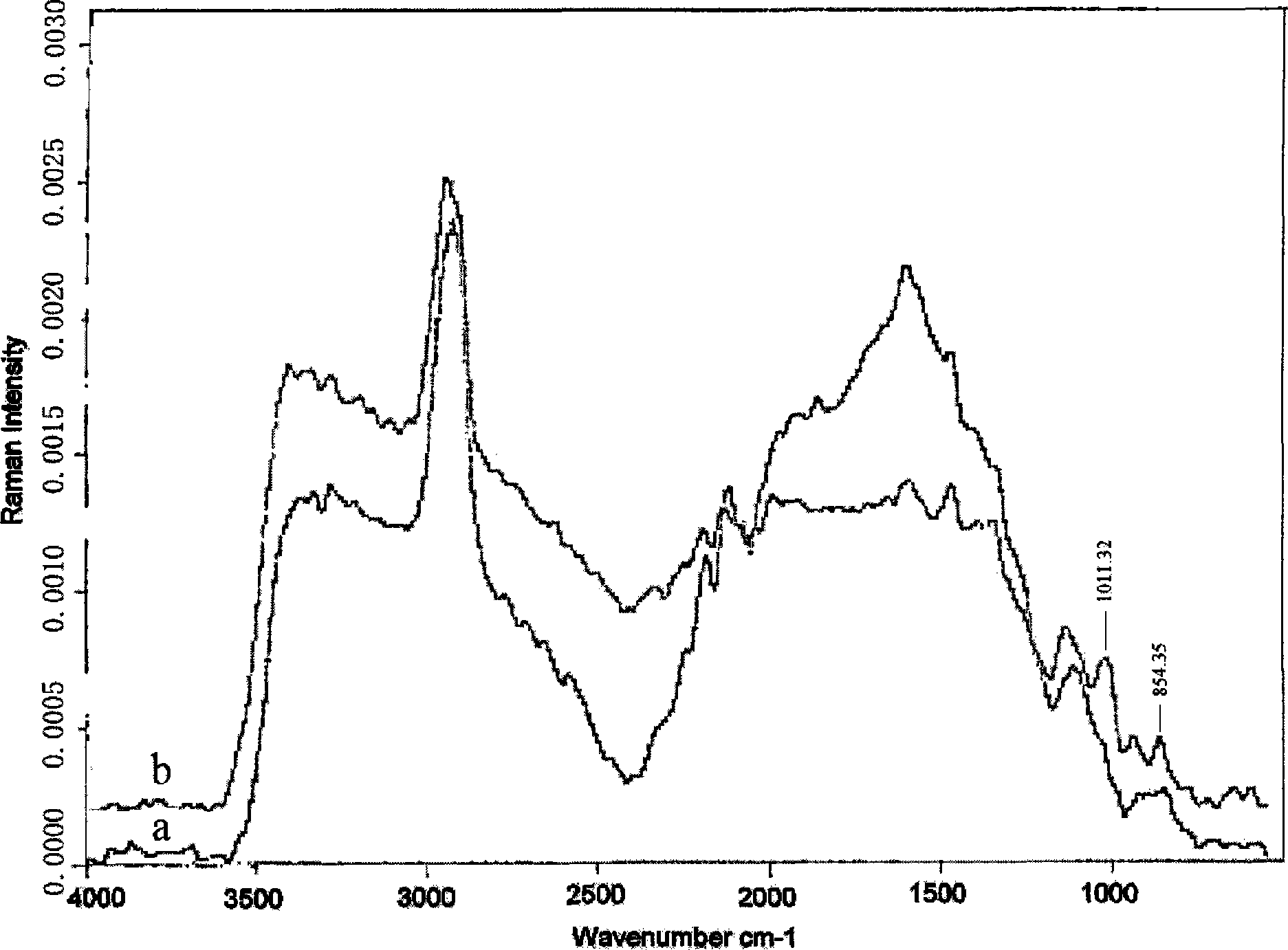

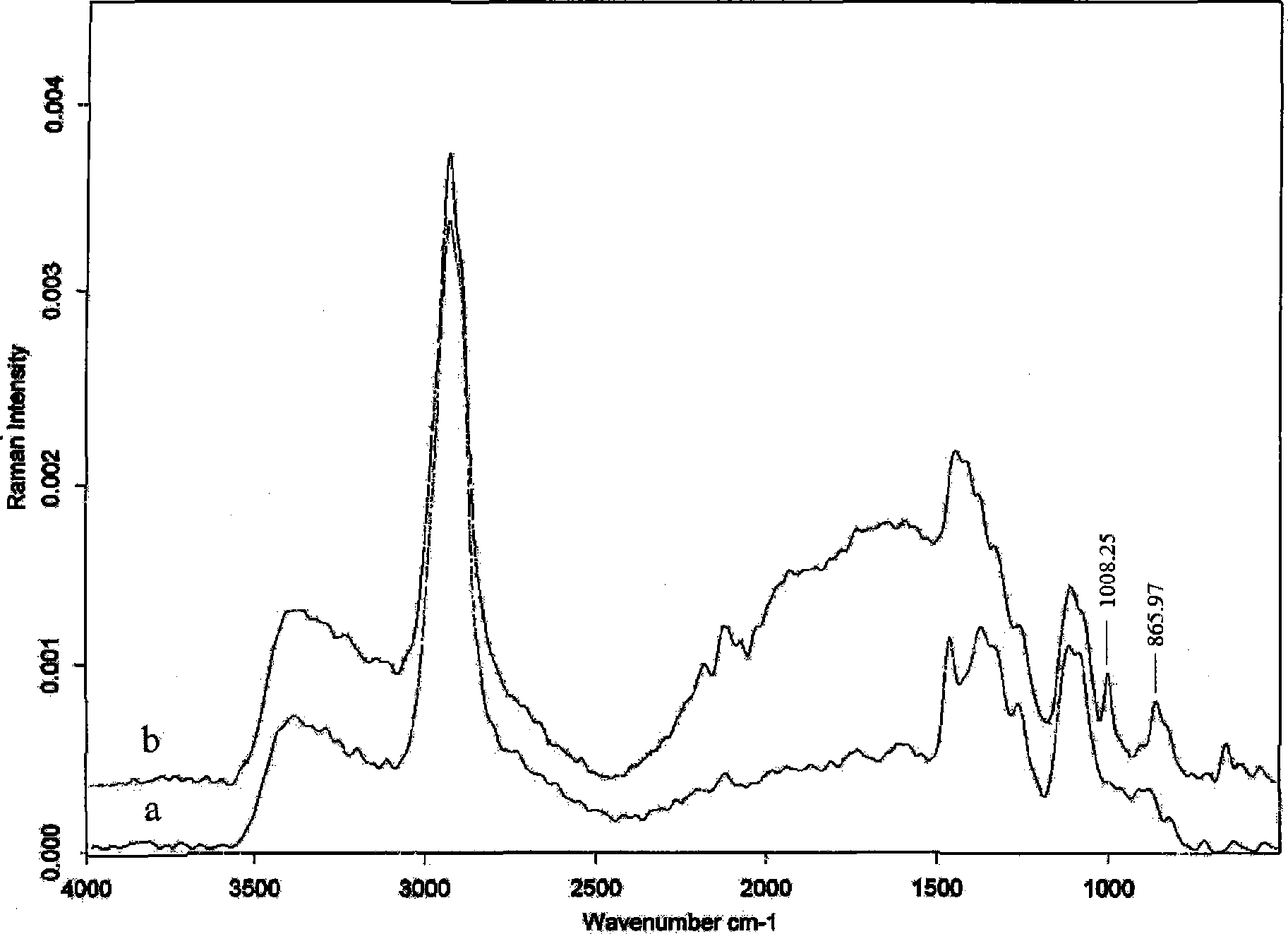

Image

Examples

Embodiment 1

[0021] The preparation method of a kind of fern polysaccharide selenite product of the present invention comprises the following steps:

[0022] (1) select the fern polysaccharide as raw material;

[0023] (2) Weighing 0.5g of P. japonica polysaccharide with a purity of more than 90% and adding it to a 250ml three-necked flask, adding 100ml of 1.2% nitric acid solution at a concentration of 1.2% by weight, stirring on a magnetic stirrer at room temperature for 10min, and standing for 12 hours. Obtain the Junaca polysaccharide suspension A;

[0024] (3) Put the Juna polysaccharide suspension A in a microwave reactor, add 1.65g of barium chloride and 0.5g of selenous acid into a three-necked flask, raise the temperature to 70°C, and set the microwave power at 300W and the frequency at 2450MHz The reaction was carried out for 0.5h, and after cooling to room temperature, a suspension B was obtained;

[0025](4) After the suspension B was filtered under reduced pressure at 0.06Mp...

Embodiment 2

[0028] The preparation method of a kind of fern polysaccharide selenite product of the present invention comprises the following steps:

[0029] (1) select the fern polysaccharide as raw material;

[0030] (2) Weighing 0.4g of the polysaccharides of Zernia japonica with a purity of more than 90% and adding it to a 250ml three-necked flask, adding 100ml of 0.6% nitric acid solution at a concentration of 0.6% by weight, stirring for 15min on a magnetic stirrer at room temperature, and standing for 15 hours, Obtain the Junaca polysaccharide suspension A;

[0031] (3) Put the suspension A of the fern polysaccharides in a microwave reactor, add 1.65g of barium chloride and 0.8g of selenous acid into a three-necked flask, heat up to 60°C, and react at a microwave power of 200W and a frequency of 2450MHz After 1.5h, after cooling to room temperature, suspension B was obtained;

[0032] (4) After the suspension B was filtered under reduced pressure at 0.07Mpa, 26ml of 3.0mol / L sulfu...

Embodiment 3

[0035] The preparation method of a kind of fern polysaccharide selenite product of the present invention comprises the following steps:

[0036] (1) select the fern polysaccharide as raw material;

[0037] (2) Weighing 1.0g of P. japonicus polysaccharide with a purity of more than 90% is added to a 250ml three-necked flask, and the concentration by weight is 100ml of 0.8% nitric acid solution, stirred on a magnetic stirrer at room temperature for 20min, and left to stand for 18 hours. Obtain the Junaca polysaccharide suspension A;

[0038] (3) Put the suspension A of the fern polysaccharide in a microwave reactor, add 1.65g of barium chloride and 2.0g of selenous acid into a three-necked flask, heat up to 45°C, and react at a microwave power of 100W and a frequency of 2450MHz 4h, after cooling to room temperature, suspension B was obtained;

[0039] (4) After the suspension B was filtered under reduced pressure at 0.08Mpa, 30ml of 3.0mol / L sulfuric acid was added to the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com