Process for producing hydrated lime by using acetylene sludge

A calcium hydroxide and production process technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of easy leakage and pollution of road surfaces, large land occupation, land erosion, etc., and achieve considerable economic benefits and production The effect of low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

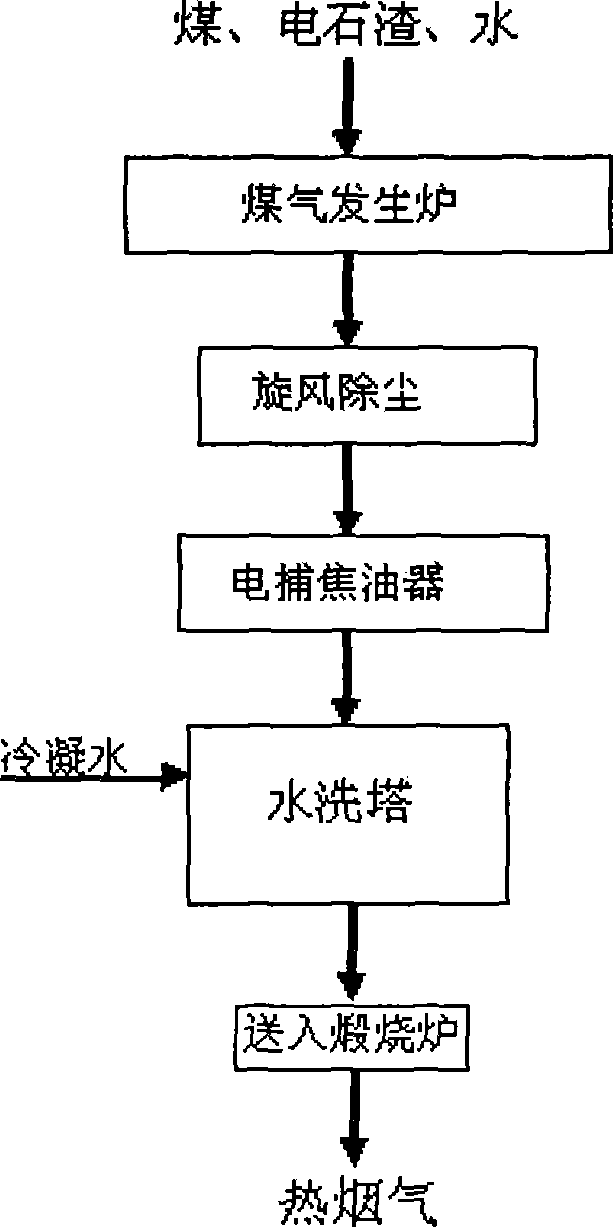

[0021] Such as figure 1 As shown in the flow chart of the production process of hot flue gas, the hot flue gas comes from the calcining furnace, specifically: the project adopts a two-stage gas generator, and the produced gas enters the water washing tower after cyclone dust removal and electric tar capture. , Into the calciner in the production workshop to provide hot flue gas for production. The project uses coal mixed with calcium carbide slag for desulfurization, the calcium-sulfur ratio (weight) is 1:5, and the desulfurization efficiency is about 60% or more.

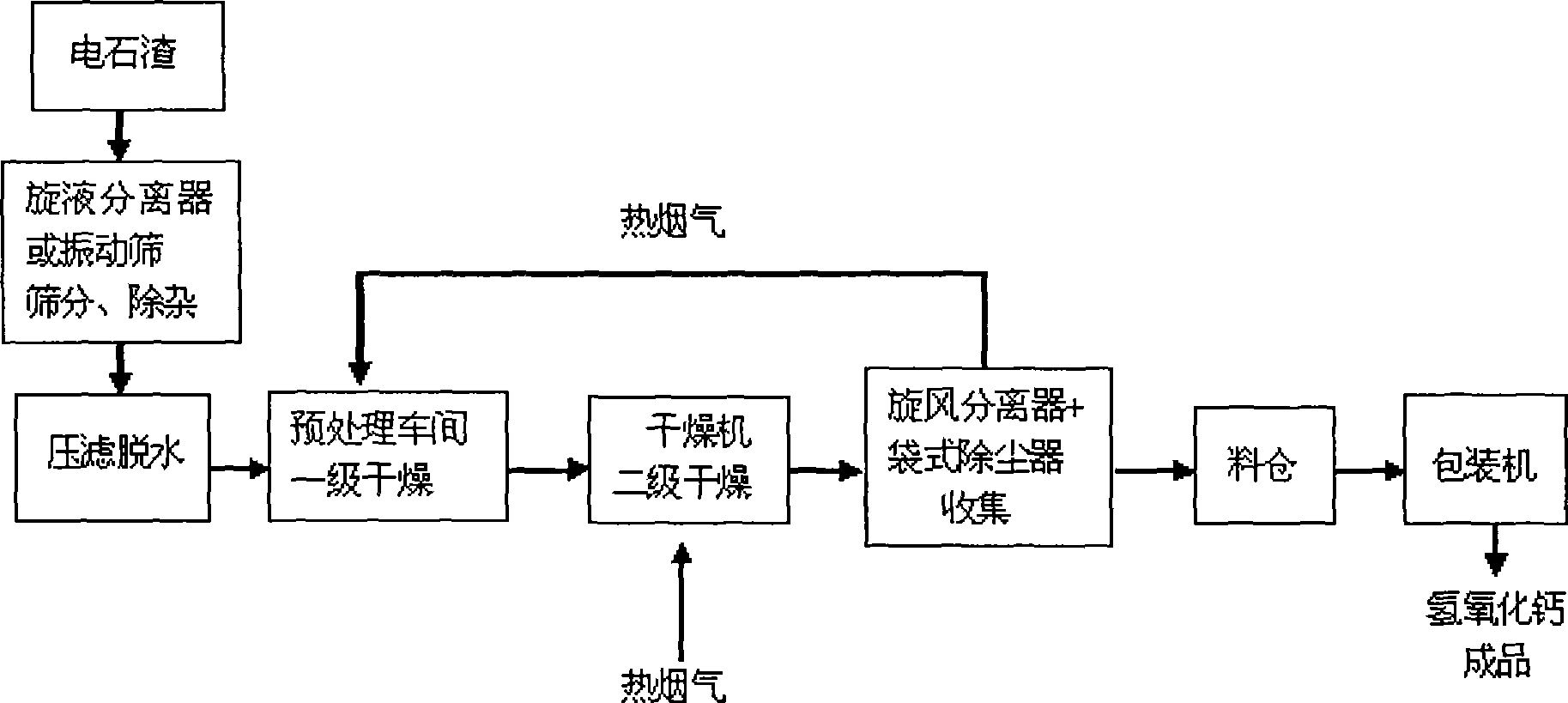

[0022] Such as figure 2 The production process flow chart of using calcium hydroxide slag to prepare calcium hydroxide is shown: because the calcium carbide slag contains a large amount of impurities, the particle size distribution of the impurities is wide, and it is not easy to separate. Before the calcium carbide slag enters the sedimentation tank, it enters the hydrocyclone or vibrating screen Wait for screening e...

Embodiment 2

[0024] The temperature of the primary drying is 50℃, and the time is 30h; the hot flue gas of the secondary drying comes from the electric furnace (the method of generating hot flue gas from the electric furnace is a conventional method, and the production process flow chart is omitted), and the temperature of the secondary drying is 200℃ , The time is 5s; the primary drying is carried out in a tumble dryer; the secondary dryer uses a flash dryer, the flash dryer also has a feeding part, the feeding part is equipped with a dispersing device, and the flash dryer is the same Working in a fully enclosed state, the flash dryer is about 3 to 8 meters high, hot flue gas enters from the bottom, and a high-speed rotating hot air flow is formed in the flash dryer. The hot air flow and the materials that are strongly dispersed by the dispersing device The material forms a suspended fluidized movement, and the heat and mass exchange is completed instantly. The other processes and the equipme...

Embodiment 3

[0026] The temperature of the primary drying is 150℃, and the time is 8h; the hot flue gas of the secondary drying comes from a hot blast stove (the hot blast stove generates hot flue gas is a conventional method, and the production process flow chart is omitted), and the temperature of the secondary drying is 600°C, the time is 1s; the primary drying is carried out in a paddle dryer; the other processes and the equipment used are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com