Biodegradable polyester composition

A technology of copolyester and composition, which is applied in the field of biodegradable copolyester composition, can solve the problems of high cost, heat resistance, insufficient mechanical performance, processing performance and anti-aging performance, and limit application fields, etc., to reduce Production cost, excellent heat resistance, effect of widening application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

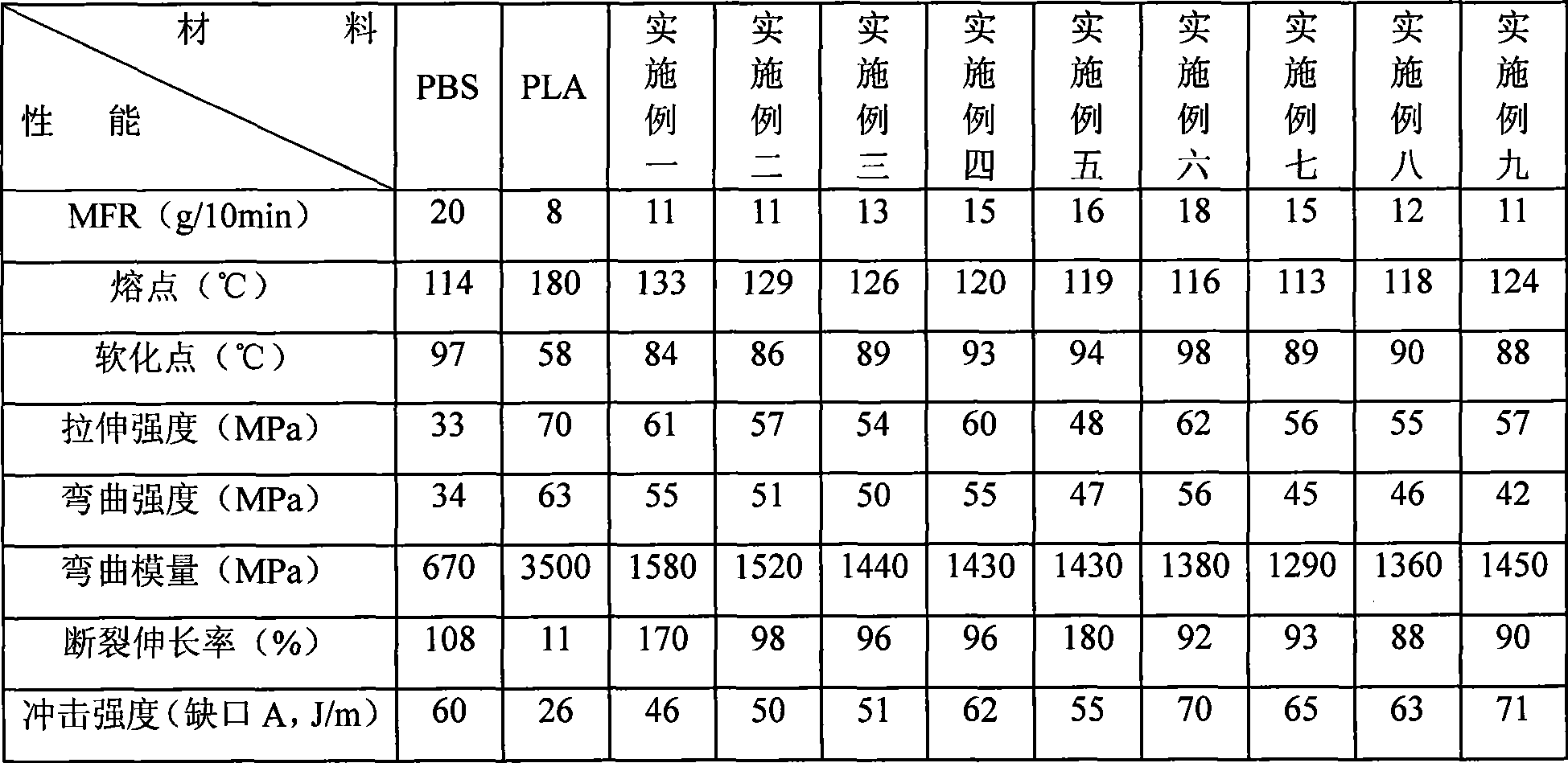

Examples

Embodiment 1

[0021] Polybutylene succinate-terephthalate 62Kg

[0022] Polylactic acid 34Kg

[0023] Dimethyl phthalate 1Kg

[0025] Put the dried above-mentioned materials into a high-speed mixer and mix for 30 minutes, then enter into a twin-screw extruder, and make a biodegradable copolyester composition masterbatch in the twin-screw extruder. The temperature of each section of the twin-screw extruder is as follows: first section: 170°C; second section: 150°C; third section: 150°C; fourth section: 150°C; fifth section: 150°C;

Embodiment 2

[0027] Polybutylene succinate-adipate 70Kg

[0028] Polylactic acid 26Kg

[0029] Diethyl phthalate 1Kg

[0030] Talc powder 2Kg

[0031] Bamboo Powder 1Kg

[0032] Put the dried above-mentioned materials into a high-speed mixer and mix for 30 minutes, then enter into a twin-screw extruder, and make a biodegradable copolyester composition masterbatch in the twin-screw extruder. The temperature of each section of the twin-screw extruder is as follows: first section: 170°C; second section: 150°C; third section: 150°C; fourth section: 150°C; fifth section: 150°C;

Embodiment 3

[0034] Polybutylene succinate-adipate 45Kg

[0035] Polylactic acid 50Kg

[0036] Dimethyl phthalate 2Kg

[0037] Bamboo powder 1Kg

[0038] Nano calcium carbonate 2Kg

[0039] Put the dried above-mentioned materials into a high-speed mixer and mix for 30 minutes, then enter into a twin-screw extruder, and make a biodegradable copolyester composition masterbatch in the twin-screw extruder. The temperature of each section of the twin-screw extruder is as follows: first section: 170°C; second section: 150°C; third section: 150°C; fourth section: 150°C; fifth section: 150°C;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com