Ba3BP3O12 crystalloid, growing method and application thereof

A 3BPO3O12, ba3bp3o12 technology, applied in the field of crystal growth, to achieve the effect of favorable mass transfer, low viscosity and fast growth speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

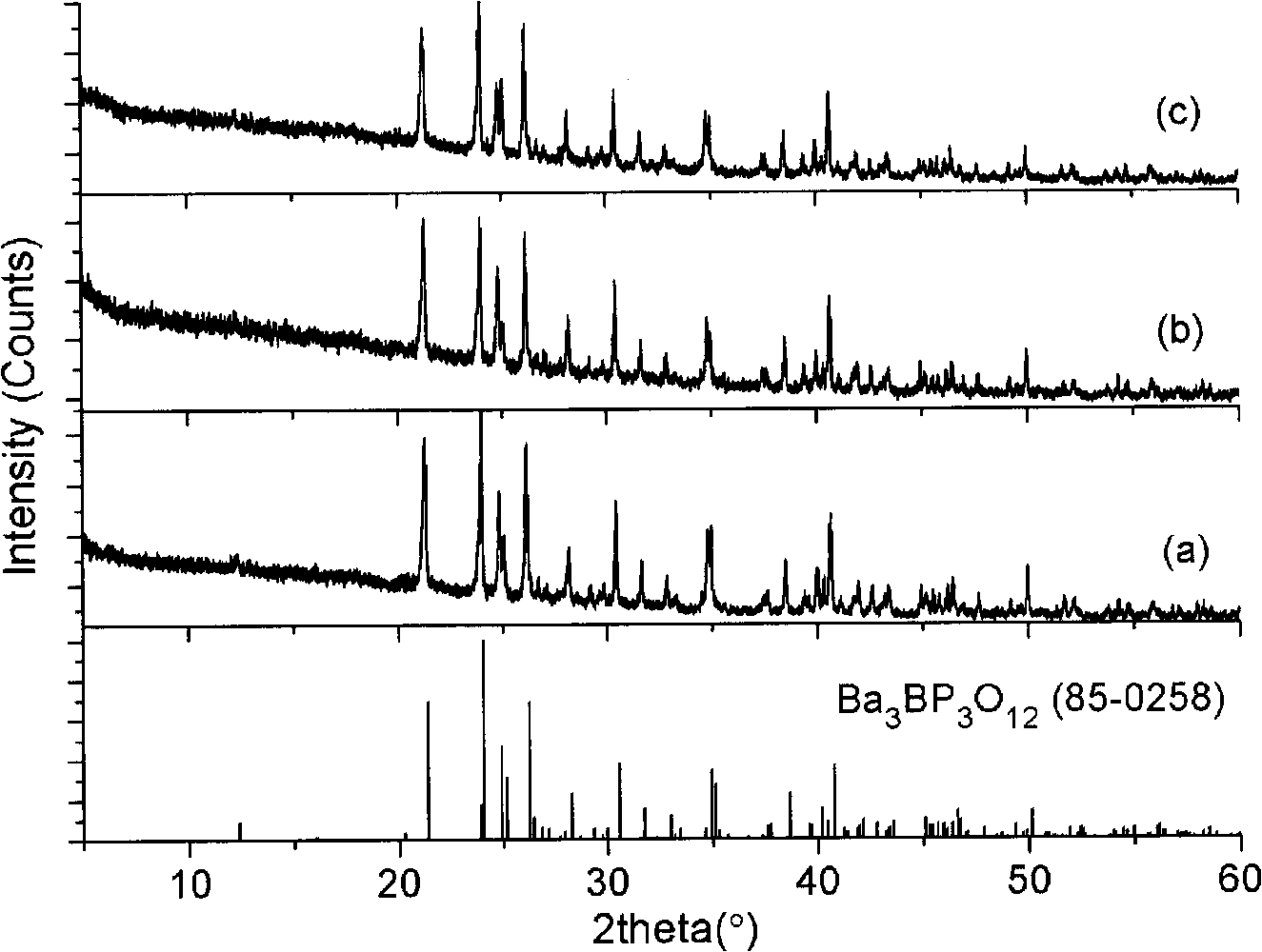

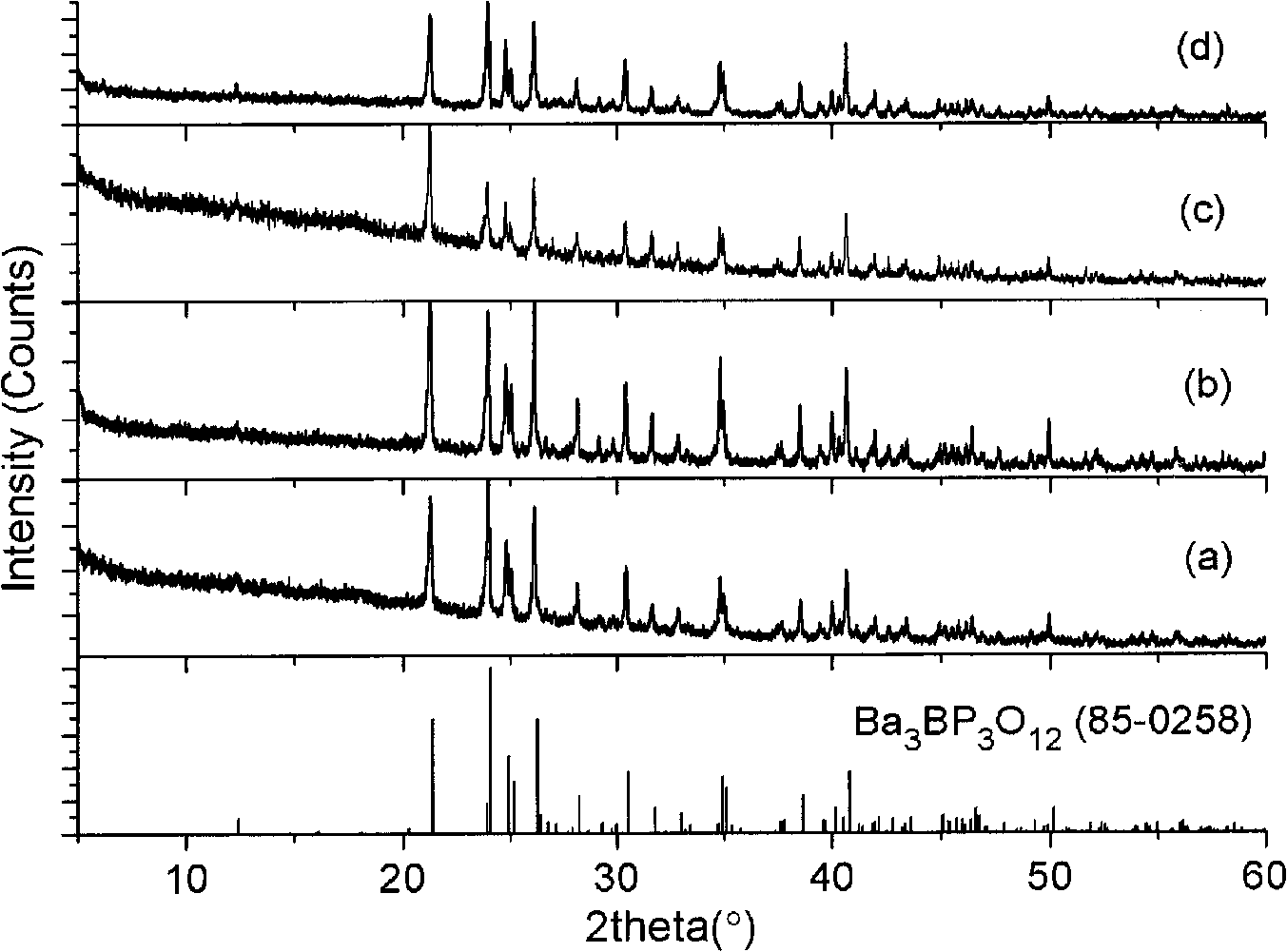

Embodiment 1

[0060] x=0, y=0, z=0, the BaCO 3 , NH 4 h 2 PO 4 、H 3 BO 3 Weigh according to the above proportion, mix evenly, and pre-fire at 800°C for 1 hour to remove moisture, carbon dioxide and ammonia in the raw material of the mixture. After grinding evenly with NaF flux (the distribution ratio of each component is Ba 3 BP 3 o 12 :B 2 o 3 :P 2 o 5 :NaF=1:1:1:3), put them into a platinum crucible together, heat up and melt to prepare for growth. The rotational speed of the seed crystal was 5 rpm. Adjust the appropriate crystal inoculation temperature. When the seed crystal on the seed rod just contacts the melt, keep the position of the seed crystal unchanged, and start to slowly cool down (cooling rate = 0.1°C / hour). After growing the crystal, lift the crystal to make it Detach from the melt surface, and anneal at a position about 1cm away from the liquid surface to eliminate thermal stress. Then slowly cool down to room temperature, and take out the crystals. The cryst...

Embodiment 2

[0062] x=0.010, y=0, z=0, the BaCO 3 , (NH 4 ) 2 HPO 4 , B 2 o 3 、Eu 2 o 3 Weigh according to the above proportion, mix evenly, and pre-calcine at 450°C for 9 hours to remove moisture, carbon dioxide and ammonia in the raw material of the mixture. After grinding evenly with NaF flux (the distribution ratio of each component is Ba 3 BP 3 o 12 :B 2 o 3 :P 2 o 5 :NaF=1:1:1:3), put them into a platinum crucible together, heat up and melt to prepare for growth. The rotational speed of the seed crystal was 5 rpm. Adjust the appropriate crystal inoculation temperature. When the seed crystal on the seed rod just contacts the melt, keep the position of the seed crystal unchanged, and start to slowly cool down (cooling rate = 0.05°C / hour). After growing the crystal, lift the crystal to make it Detach from the melt surface, and anneal at a position about 1cm away from the liquid surface to eliminate thermal stress. Then slowly cool down to room temperature, and take out t...

Embodiment 3

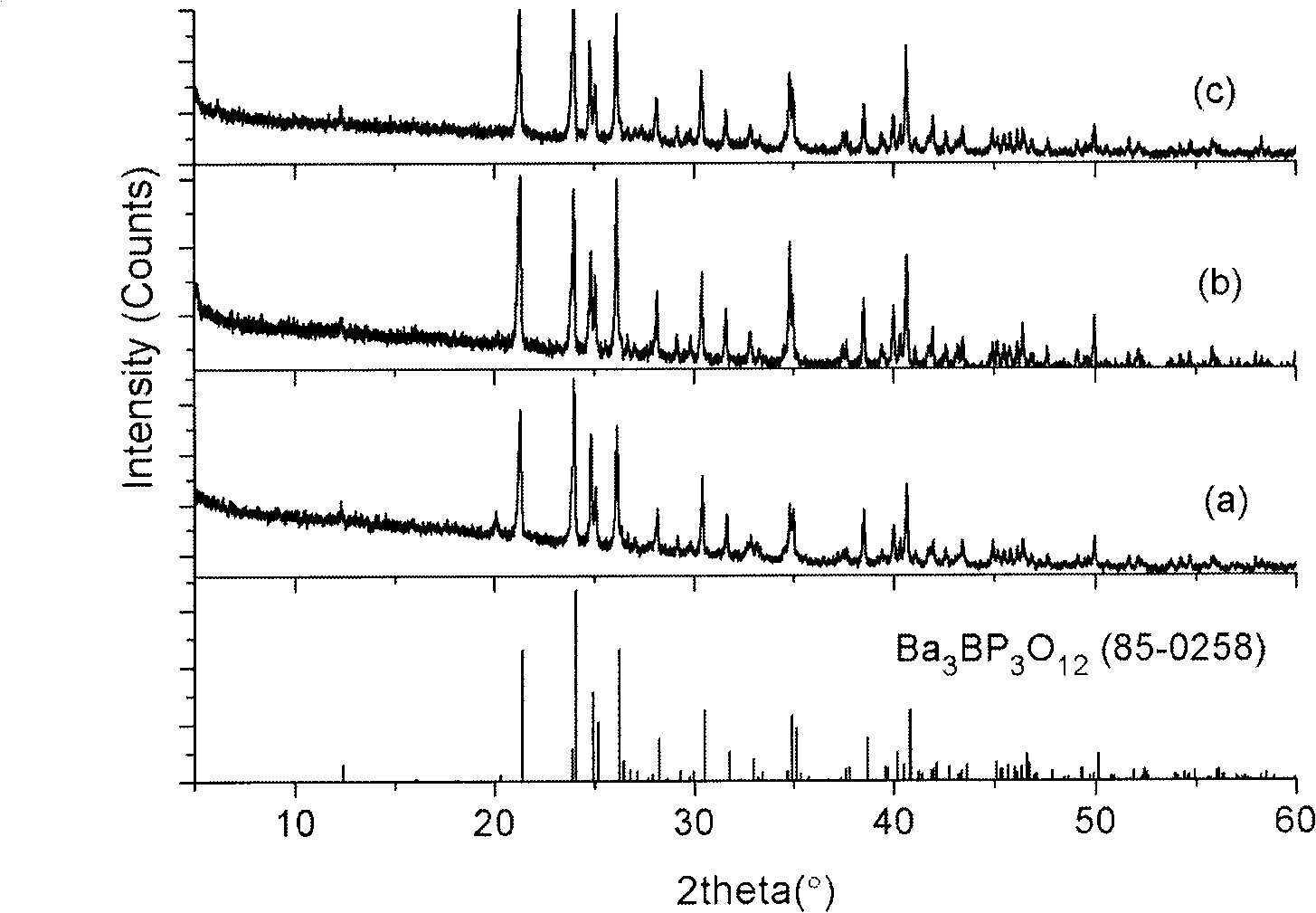

[0064] Repeat the method of Example 2 according to the content of each component and the crystal growth parameter specified in the following table 1 to obtain Ba 3 BP 3 o 12 :Nd 3+ (1%), Na + (1%) crystals. Crystal powder XRD pattern see figure 1 (c).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com