Bentonite waterproof carpet and manufacturing method thereof

A bentonite waterproof blanket and technology of bentonite, applied in the field of bentonite waterproof blanket, can solve the problems of sodium-based bentonite loss of characteristics, complex water quality and environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

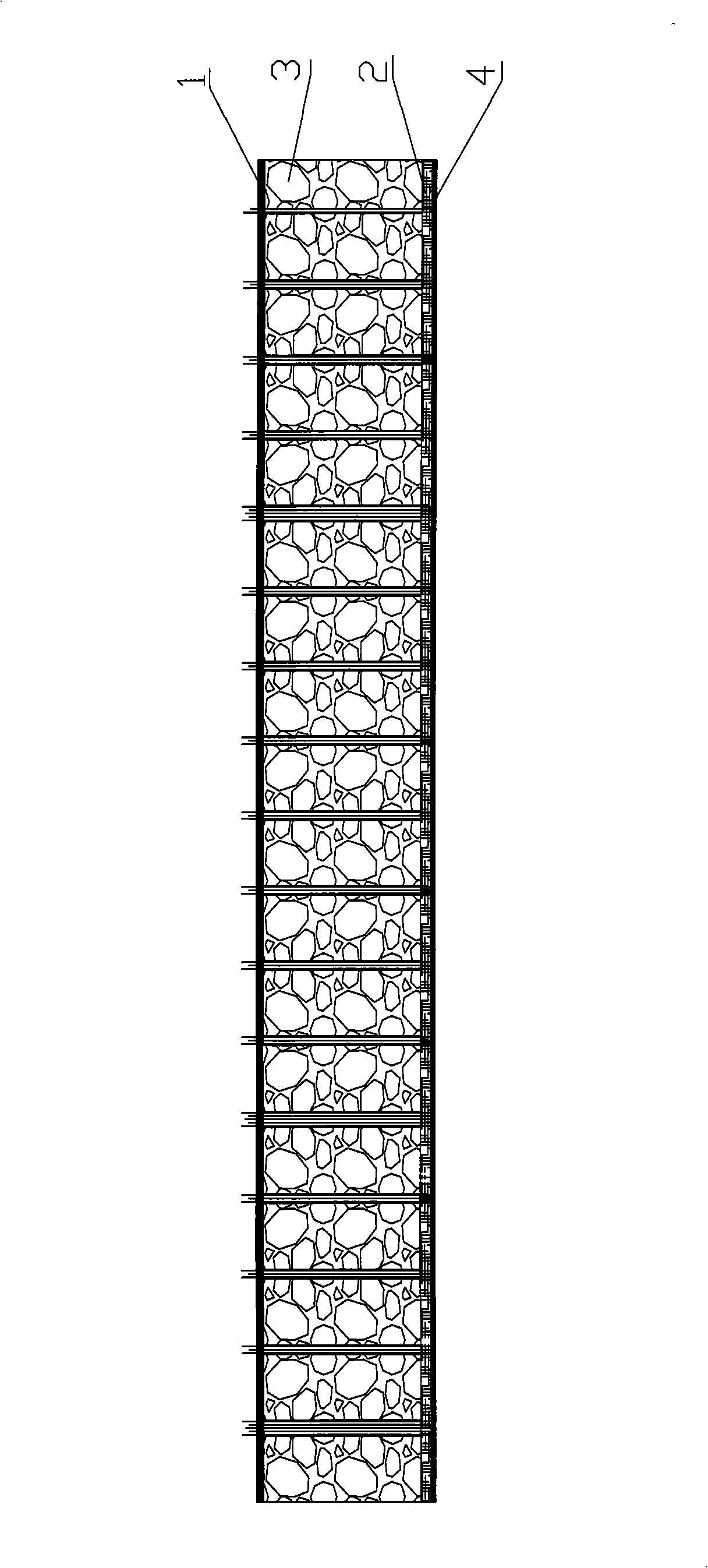

Image

Examples

Embodiment 1

[0028] Prepare the waterproof blanket of the present invention according to the following steps:

[0029] (1) Mix dry cationic polyacrylamide and anionic polyacrylamide with a weight ratio of 1:1.5 and fully stir for 2 minutes to prepare a primary mixture;

[0030] (2) According to the mass ratio of sodium bentonite: primary mixture=100:1.5, slowly add the primary mixture to the high expansive sodium bentonite particles with FS≥24ml / 2g, and fully stir for 10 minutes at room temperature. Make a bentonite mixture;

[0031] (3) Spread the bentonite mixture evenly on the bottom woven geotextile, the mass of the bentonite mixture per unit area is 3.75kg±0.25kg / m 2 , Spread a layer of polypropylene geotextile or non-woven fabric on the upper layer of the bentonite mixture, and composite the bottom geotextile with the surface geotextile or non-woven fabric by needle punching, and fix the bentonite mixture on the bottom layer Between the fabric and the surface fabric, make a waterproof bl...

Embodiment 2

[0037]The waterproof blanket is prepared according to the method of Example 1, wherein the weight ratio of cationic polyacrylamide to anionic polyacrylamide is 1:5; sodium-based bentonite particles: primary mixture=100:2; within a unit area of the waterproof blanket The mass of bentonite mixture is 4.0kg±0.25kg / m 2 .

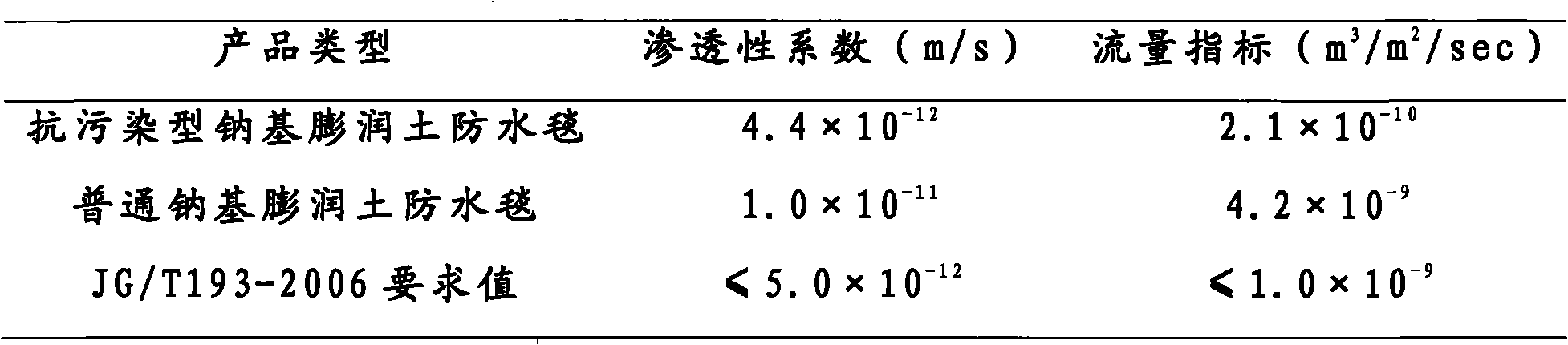

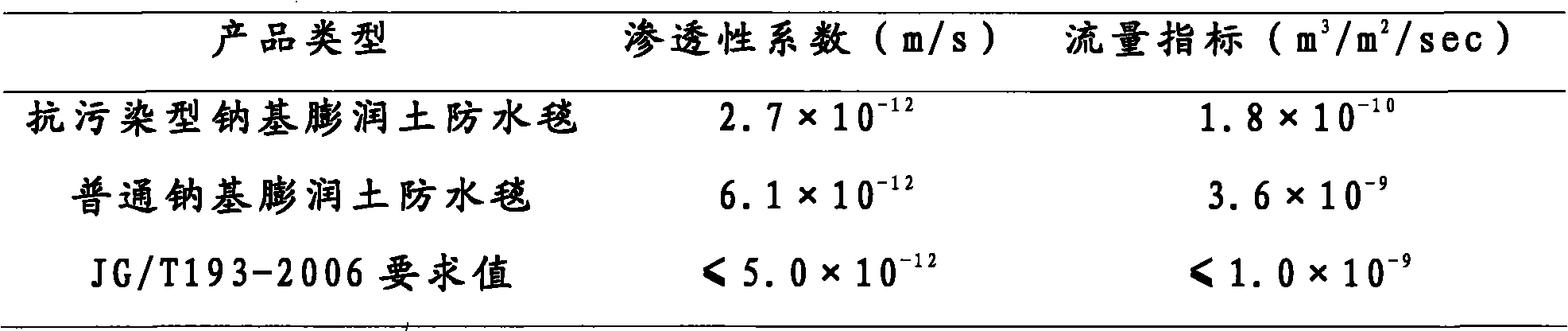

[0038] Choose a water sample with a pH of 6.48 and a conductivity of 11.33ms / m. The water contains a large amount of nitrate, sulfate, magnesium ion, sodium ion, and calcium ion, of which sulfate is 428mg / L and nitrate is 30.2mg / L.

[0039] Take a sufficient amount of water samples and test them in accordance with the treatment method described in Example 1 to obtain permeability coefficients and flow indicators respectively. The results are shown in the following table:

[0040]

[0041] It can be seen that in a complex water environment, the waterproof blanket of the present invention still has a certain waterproof effect on the above-mentioned high-concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com