Resonance micro electromechanical system magnetic field sensor and measuring method thereof

A technology of micro-electromechanical systems and magnetic field sensors, which is applied in chemical instruments and methods, the size/direction of magnetic fields, and components of TV systems, etc. It can solve the problems of high power consumption, high manufacturing process requirements, and complex structures of comb resonators. problems, to achieve the effect of reliable electrical contact, high sensitivity, high precision and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

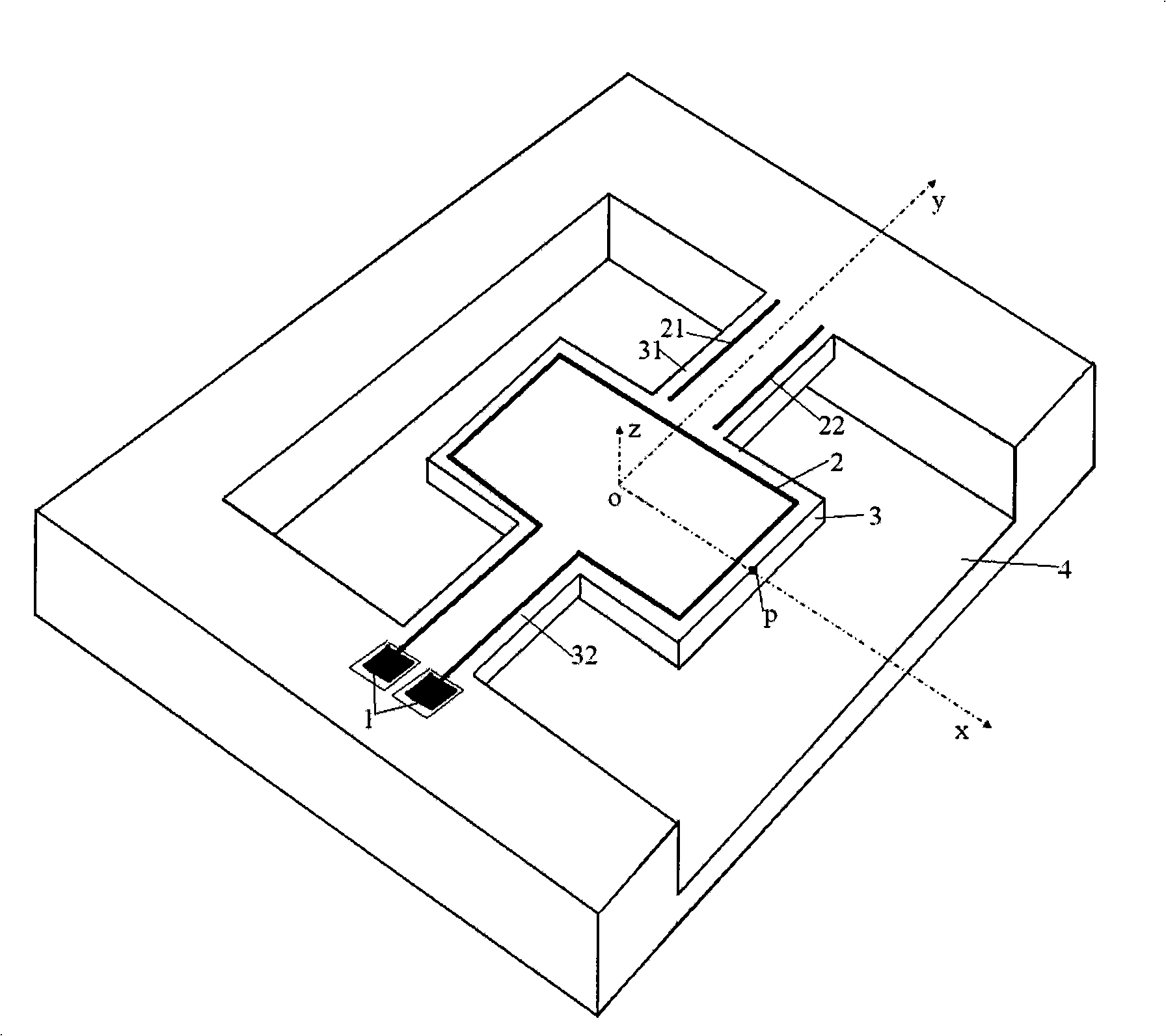

Embodiment 1

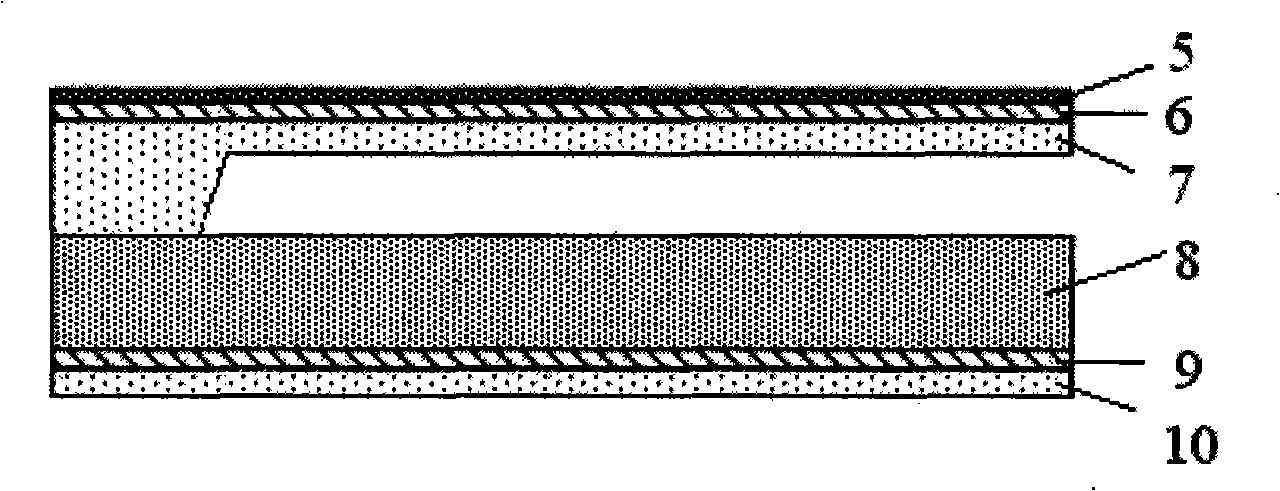

[0052] A resonant MEMS magnetic field sensor includes a substrate 4, a cantilever plate 3 and metal wires 2, the cantilever plate 3 is arranged on the substrate 4 in parallel, and the metal wire 2 is arranged on the cantilever plate 3. The metal wire 2 may be made of Al, Au, etc., and the metal wire 2 and the anchor region 1 are obtained by etching. The metal wire 2 drives the suspension wall plate 3 to vibrate, and the amplitude of the vibration depends on the magnitude of the current applied to the metal wire 2 and the strength of the magnetic field.

[0053] In this embodiment, the metal wires 2 can be plated on the upper surface of the cantilever plate 3 by evaporation or electroplating, and the metal wires can also be arranged on the above positions by sputtering. When the cantilever plate is vibrated by magnetic force excitation, an insulating layer needs to be provided between the metal wire 2 and the cantilever plate 3 . The material of the metal wire 2 can be aluminu...

Embodiment 2

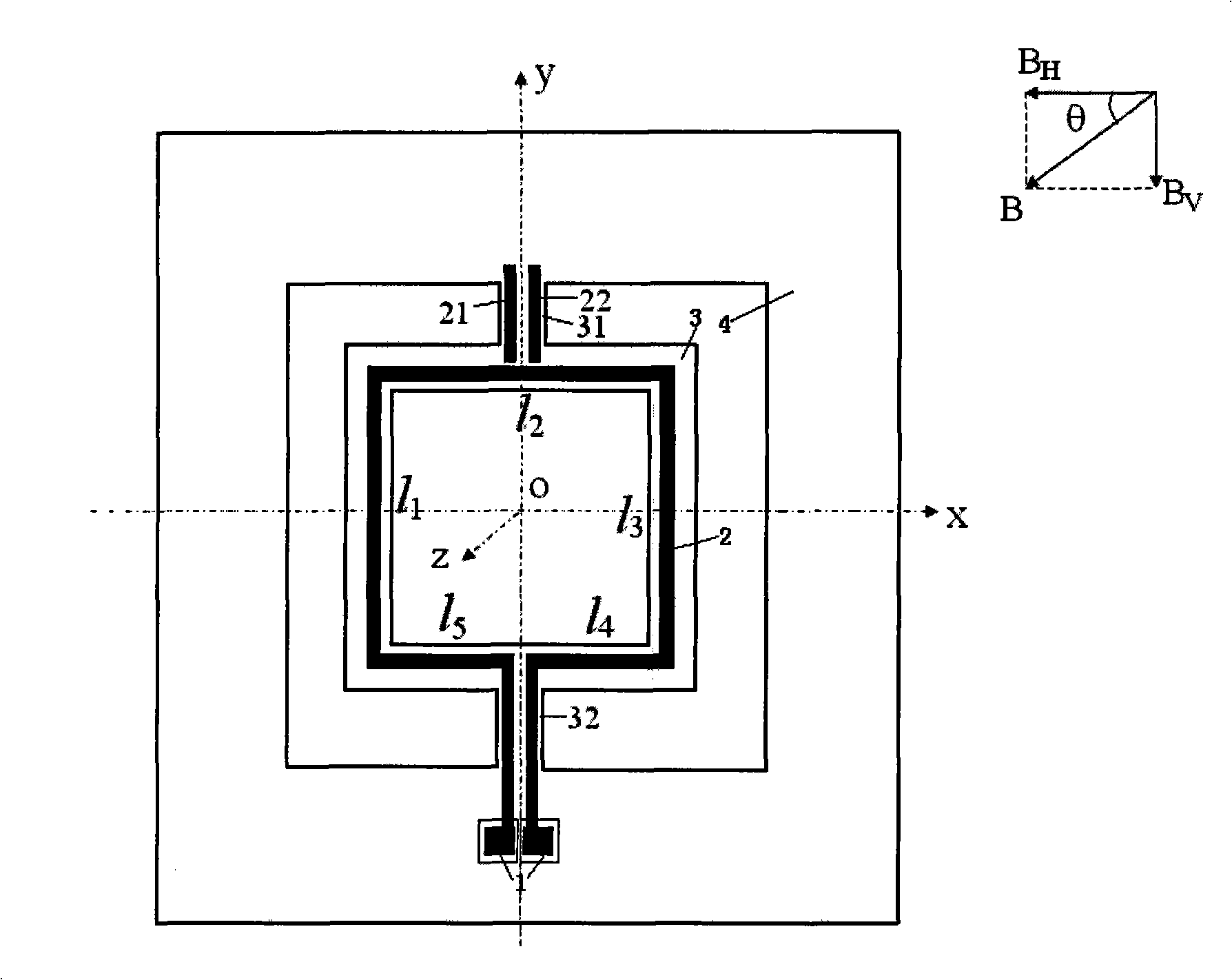

[0057] The invention is a resonant micro-electromechanical system magnetic field sensor for measuring the direction of a magnetic field, which is composed of an anchor area 1 , an induction metal wire 2 , a cantilever plate 3 and a substrate 4 . The sensor takes the substrate 4 as the plane, on the substrate 4 is provided a sensor structure composed of metal wires 2, cantilever plates 3, and anchor regions 1, which are left and right symmetrical to the center line, and the metal wires 2 drive the cantilever plates 3 to vibrate.

[0058] After the structure is completed, firstly, under the known magnitude and direction of the magnetic field, an alternating current is passed on the metal wire 2 respectively. The displacement at the second order frequency is used to calibrate k 1 / Q 1 and k 2 / Q 2 The value of , as a parameter fixed to the structure.

[0059] When measuring, first place the magnetic field sensor in the magnetic field to be measured, and then pass alternating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com