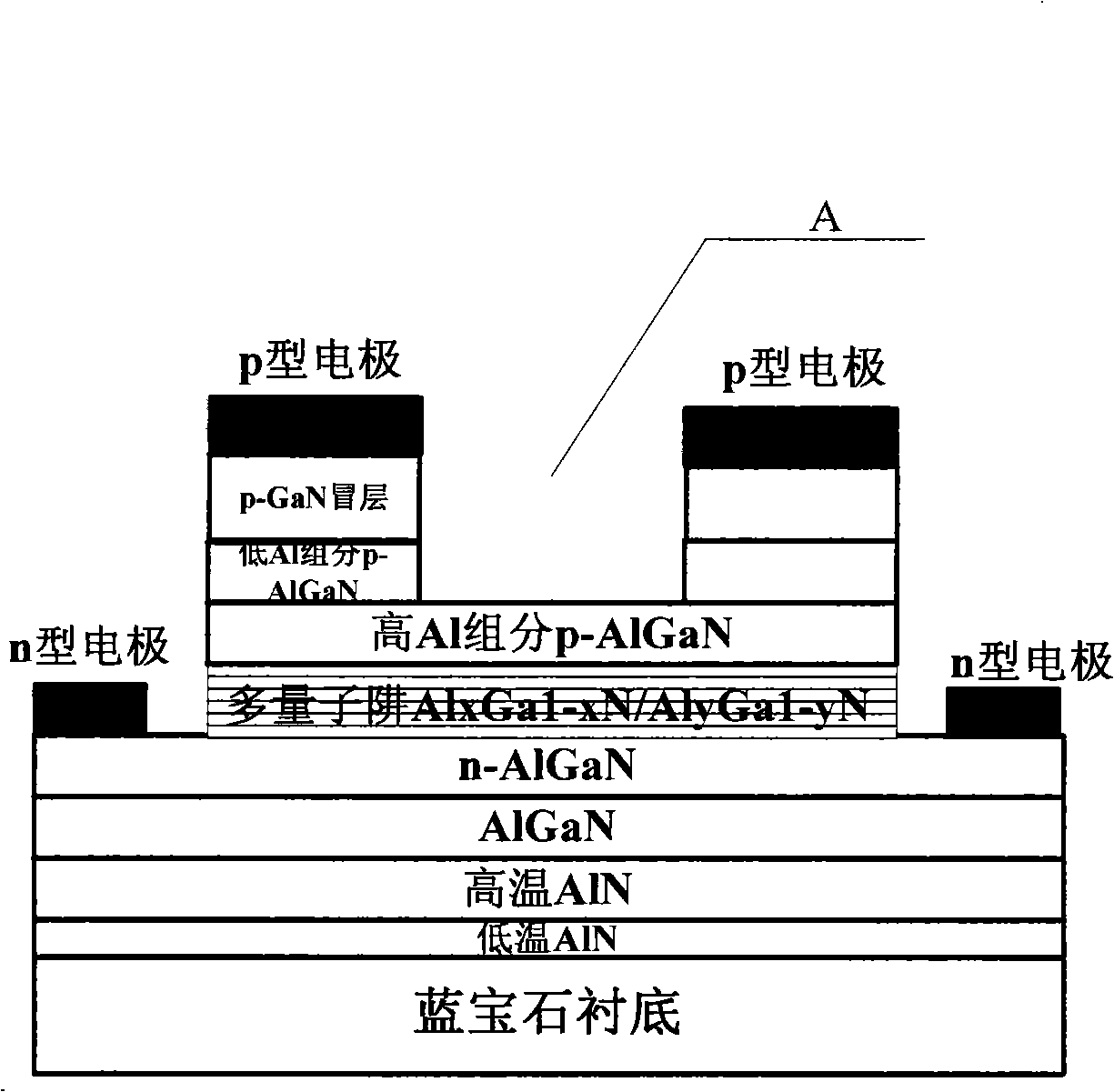

Multiple quantum well uv-LED device on sapphire substrate and manufacturing method

A technology of LED devices and sapphire substrates, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of large light loss in the middle, long light exit path, and external quantum efficiency of only 0.01%, so as to improve the output power, The effect of improving the output power and promoting the practical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, the fabrication of the device of the present invention includes two steps of material growth and device fabrication.

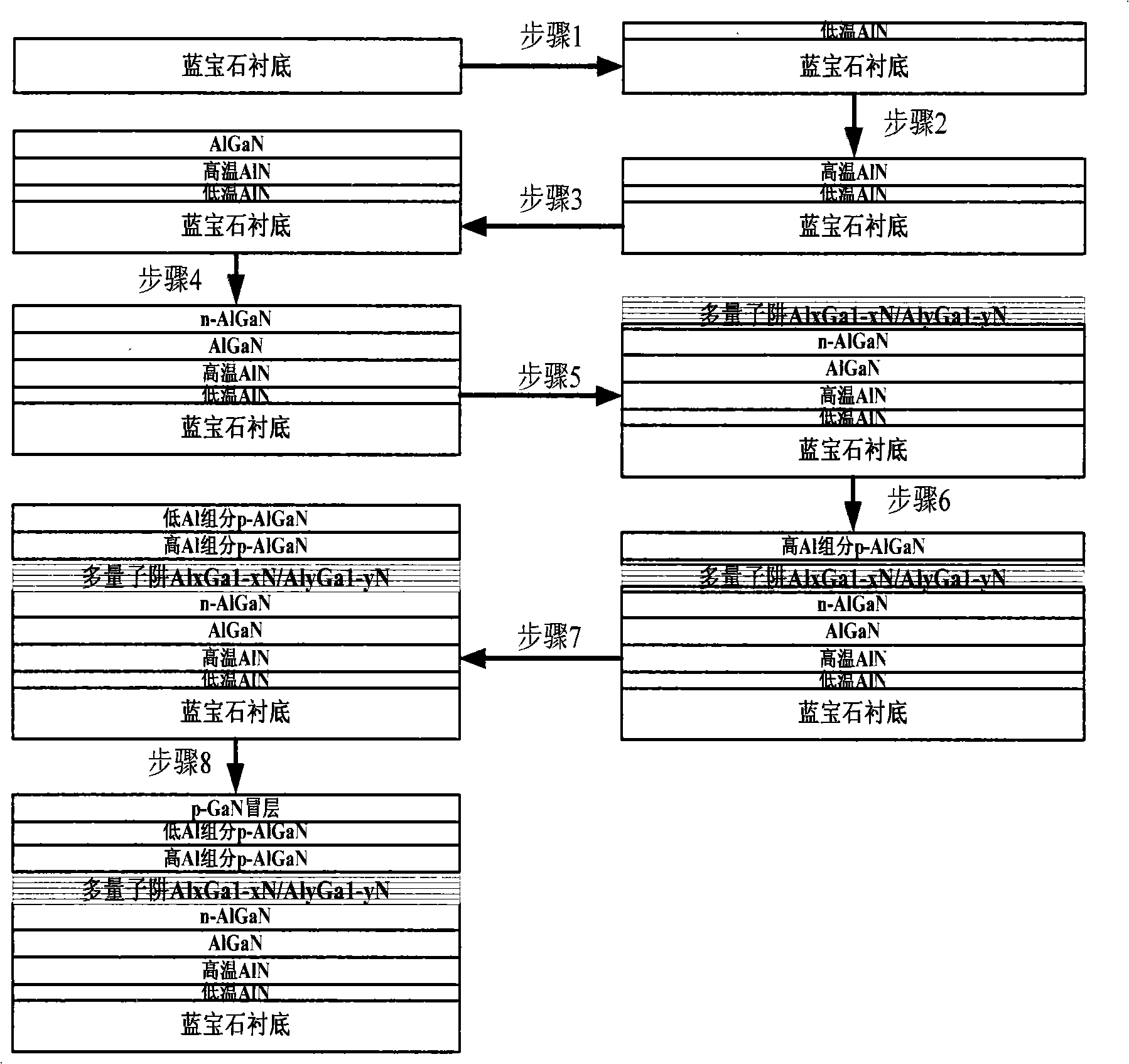

[0039] refer to figure 2 , the material growth steps of the present invention are as follows:

[0040] In step 1, a low-temperature AlN nucleation layer is grown on a sapphire substrate by MOCVD process.

[0041] Lower the substrate temperature to 600°C, maintain a growth pressure of 50Torr, flow of hydrogen at 1500sccm, flow of ammonia at 1500sccm, and feed an aluminum source at a flow rate of 28μmol / min into the reaction chamber to grow a low-temperature AlN nucleation layer with a thickness of 5nm.

[0042] Step 2, growing a high temperature AlN nucleation layer on the low temperature AlN nucleation layer.

[0043] Raise the growth temperature to 1050°C, keep the growth pressure at 50 Torr, the flow rate of hydrogen gas at 1500 sccm, the flow rate of ammonia gas at 1500 sccm, and feed the aluminum source with a flow rate of 28 μmol / m...

Embodiment 2

[0073] Embodiment 2, the fabrication of the device of the present invention includes two steps of material growth and device fabrication.

[0074] Wherein the material growth step is identical with embodiment one, as figure 2 shown.

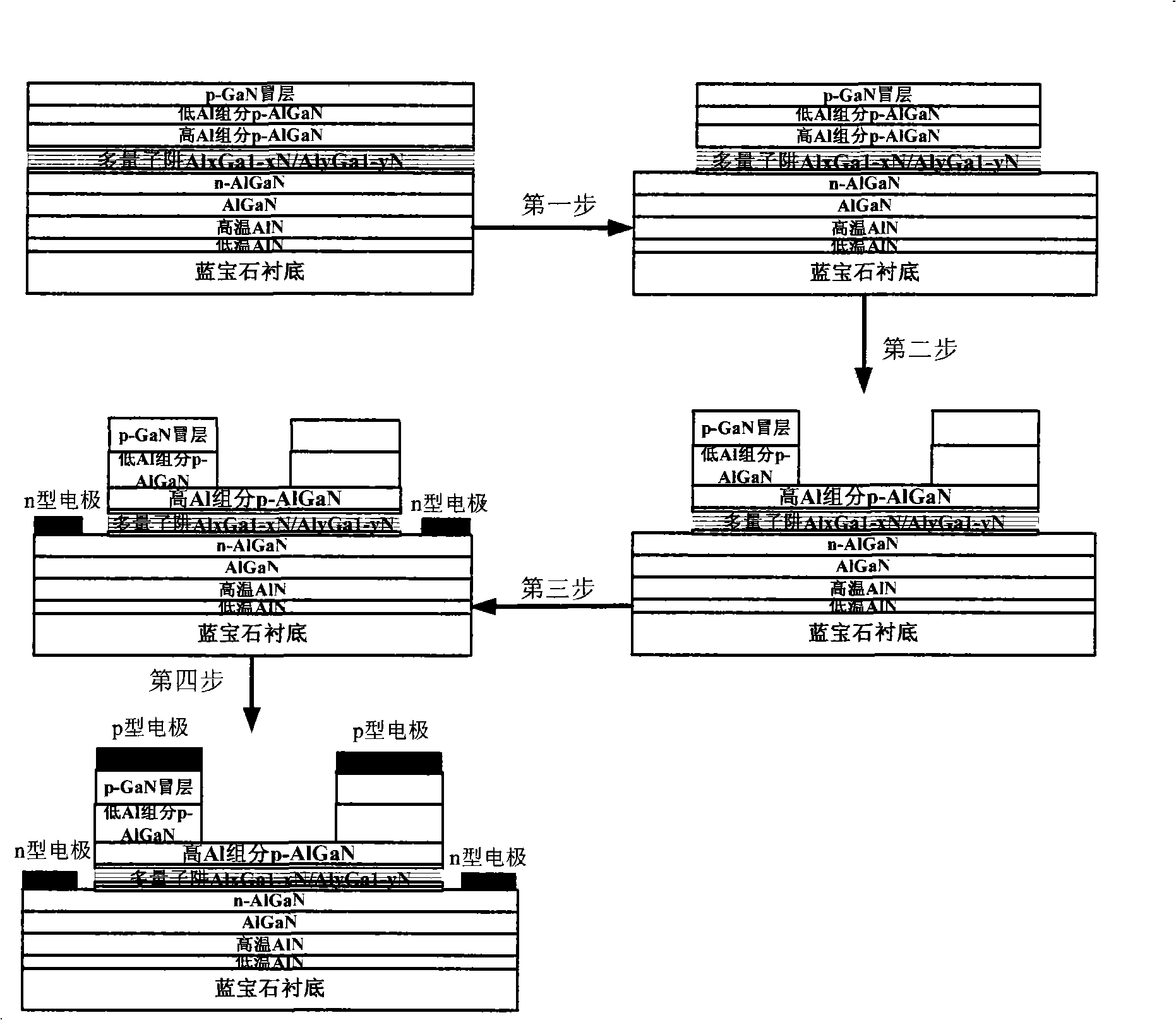

[0075] The device is made as image 3 As shown, the specific steps are as follows:

[0076] The first step is to etch the mesa to the n-type AlGaN layer on the p-type GaN capping layer by using ICP or RIE process.

[0077] Deposit SiO with a thickness of about 300nm using electron beam evaporation equipment 2 layer as an etch mask layer. Due to the slow etch rate of AlGaN material, this step is added to form SiO on the sample 2 The double-layer mask pattern that works together with the photoresist is more conducive to protecting the surface of the unetched area;

[0078] Shake the positive glue on the sample sheet at a speed of 5000 rpm, and then bake it in an oven at a temperature of 90°C for 15 minutes, and form the pattern required for ...

Embodiment 3

[0092] Embodiment 3, the fabrication of the device of the present invention includes two steps of material growth and device fabrication.

[0093] Wherein the material growth step is identical with embodiment one, as figure 2 shown.

[0094] The device is made as image 3 As shown, the specific steps are as follows:

[0095] The first step is to etch the mesa to the n-type AlGaN layer on the p-type GaN capping layer by using ICP or RIE process.

[0096] Deposit SiO with a thickness of about 300nm using electron beam evaporation equipment 2 layer as an etch mask layer. Due to the slow etch rate of AlGaN material, this step is added to form SiO on the sample 2 The double-layer mask pattern that works together with the photoresist is more conducive to protecting the surface of the unetched area;

[0097] Shake the positive glue on the sample sheet at a speed of 5000 rpm, and then bake it in an oven at a temperature of 90°C for 15 minutes, and form the pattern required for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com