Beta-type zeolite for scr catalyst and method for converting nitrogen oxide using the zeolite

一种SCR催化剂、氮氧化物的技术,应用在催化剂活化/制备、分子筛催化剂、化学仪器和方法等方向,能够解决还原性能降低、不能使用、不十分清楚等问题,达到低温NOX还原性优良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Use sodium silicate aqueous solution, aluminum sulfate aqueous solution and the composition of the slurry product is SiO 2 : 0.05Al 2 o 3 The ratio is reacted under stirring to obtain a slurry product, which is washed after dehydration to make granular amorphous aluminosilicate.

[0107] Next, with the composition of the reaction mixture as SiO 2 : 0.05Al 2 o 3 :0.67TEAF:11.0H 2 The ratio of O was mixed, and 0.36 parts of seed crystal (HSZ940NHA manufactured by TOSOH CORPORATION) was added to 100 parts of the composition, and hydrothermal synthesis was carried out at 155° C. in a reactor for 72 hours to crystallize. The crystallized slurry was washed and dried at 110°C. (TEAF: Tetraethyl fluoride hydrate 50%) This dried powder was sintered at 600°C to obtain SiO 2 / Al 2 o 3 Beta zeolite with a molar ratio of 25.

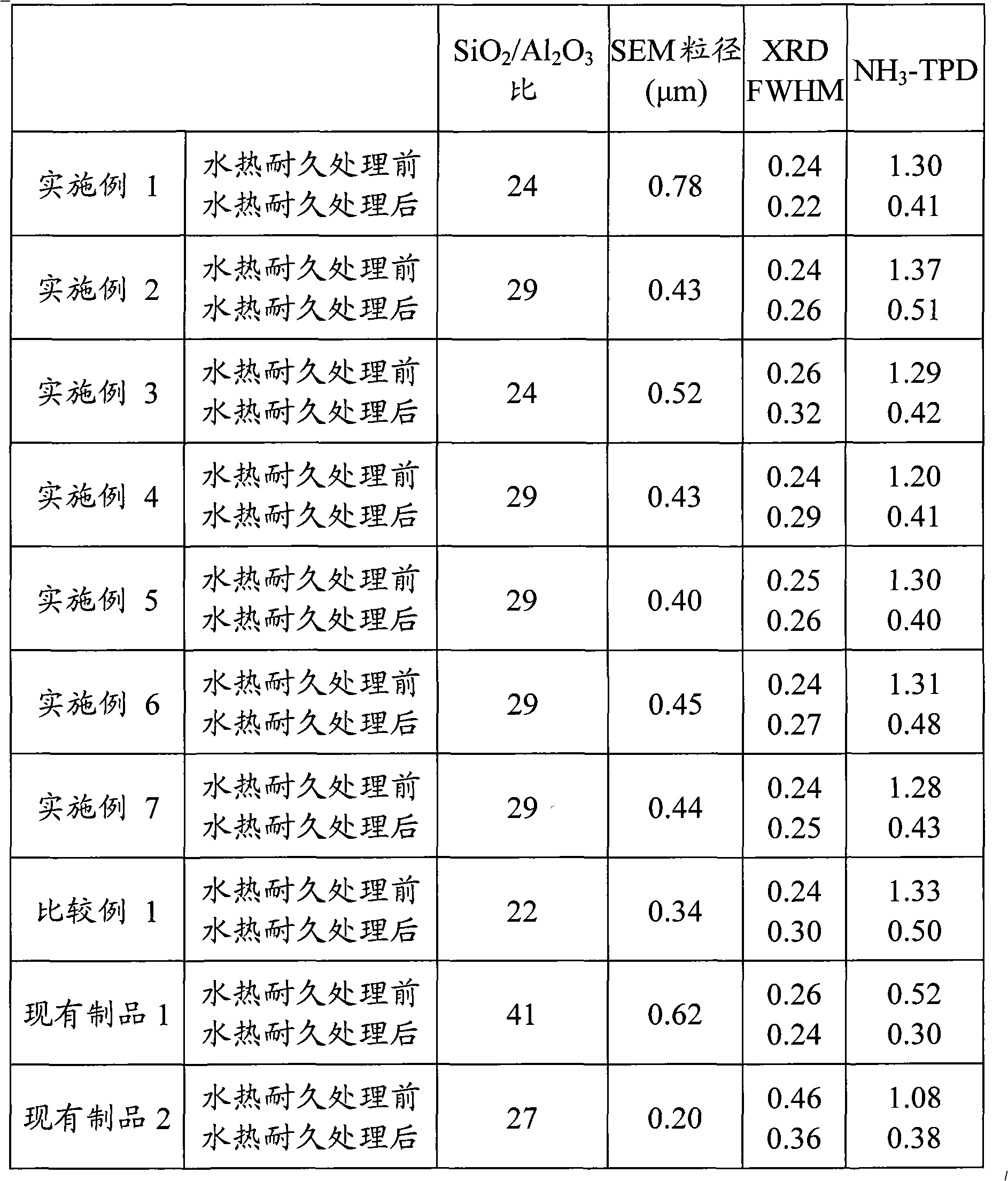

[0108] SiO of the obtained zeolite beta 2 / Al 2 o 3 Table 1 shows the molar ratio, SEM particle size, half-width of the main diffraction peak (2θ...

Embodiment 2

[0110] The composition of the raw material slurry obtained by using an aqueous solution of sodium silicate and an aqueous solution of aluminum sulfate is SiO 2 : 0.034Al 2 o 3 , the composition of the reaction mixture is SiO 2 : 0.034Al 2 o 3 : 0.16TEAOH : 9.9H 2 O, the hydrothermal synthesis conditions are 66 hours at 150°C, and the sintering temperature is 600°C. In addition, the same treatment is carried out as in Example 1 to synthesize SiO 2 / Al 2 o 3 Beta zeolite with a molar ratio of 29. (TEAOH: 35% aqueous solution of tetraethylammonium hydroxide)

[0111] SiO of the obtained zeolite beta 2 / Al 2 o 3 Table 1 shows the molar ratio, SEM particle size, half-width of the main diffraction peak (2θ=22.4°) of X-ray crystal diffraction, and the amount of ammonia adsorption after hydrothermal treatment.

Embodiment 3

[0113] The composition of the raw material slurry obtained by using an aqueous solution of sodium silicate and an aqueous solution of aluminum sulfate is SiO 2 : 0.07Al(OH) 3 , the composition of the reaction mixture is SiO 2 : 0.07Al(OH) 3 : 0.10KOH: 0.30TEAOH: 9.9H 2 O, the seed crystal uses HSZ930NHA manufactured by TOSOHCORPORATION, the hydrothermal synthesis condition is 150°C for 88 hours, and the sintering temperature is 600°C, except that, the same treatment as Example 1 is carried out to synthesize SiO 2 / Al 2 o 3 Beta zeolite with a molar ratio of 24.

[0114] SiO of the obtained zeolite beta 2 / Al 2 o 3 Table 1 shows the molar ratio, SEM particle size, half-width of the main diffraction peak (2θ=22.4°) of X-ray crystal diffraction, and the amount of ammonia adsorption after hydrothermal treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com