Fabricating method of stainless cast iron cooker

A production method and technology of cookware, which are applied in the production of cookware and the field of cast iron cookware, can solve the problems of cast iron cookware such as easy rust, short service life, poor wear resistance and corrosion resistance, etc. Long life and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

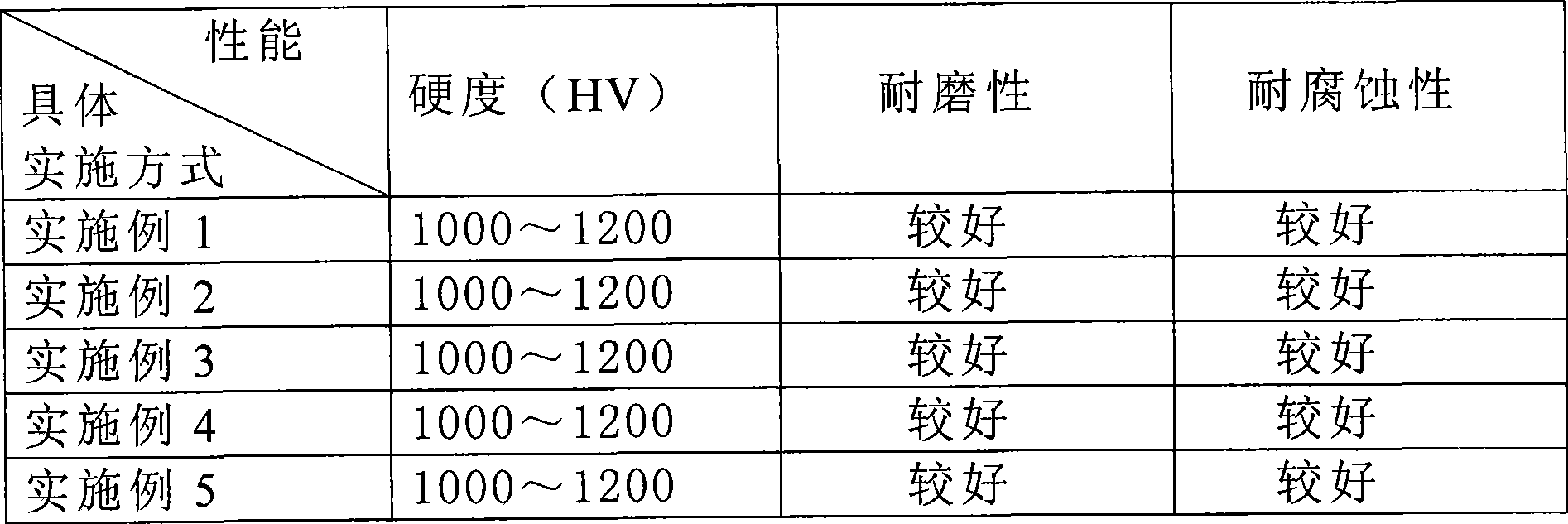

Examples

Embodiment 1

[0028] Choose No. 22 cast iron as the raw material, and use ordinary technology to smelt it at a temperature of 800-900 ° C. After smelting, it will be processed into a pot semi-finished product according to the shape of the pot according to the existing method of casting and processing pots, and then through ordinary sanding. The equipment sands off the oxide skin on the surface of the semi-finished cast iron pot and removes the dust on the surface. Use ordinary grinding equipment to grind the mouth of the semi-finished cast iron pot into a rounded corner, and drill holes for the handle on the side of the semi-finished cast iron pot.

[0029] Put the above-mentioned semi-finished cast iron pots after drilling into a vacuum nitriding furnace with good sealing performance. The space of the vacuum nitriding furnace is 2 cubic meters, and 200 semi-finished cast iron pots of 32 cm can be placed in it at one time. Use a vacuum pump Pump out the air with a volume fraction of 90%, kee...

Embodiment 2

[0031] Choose No. 22 cast iron as the raw material, and use ordinary technology to smelt it at a temperature of 800-900 ° C. After smelting, it will be processed into a pot semi-finished product according to the shape of the pot according to the existing method of casting and processing pots, and then through ordinary sanding. The equipment sands off the oxide skin on the surface of the semi-finished cast iron pot and removes the dust on the surface. Use ordinary grinding equipment to grind the mouth of the semi-finished cast iron pot into a rounded corner, and drill holes for the handle on the side of the semi-finished cast iron pot.

[0032] Put the above-mentioned semi-finished cast iron pots after drilling into a vacuum nitriding furnace with good sealing performance. The space of the vacuum nitriding furnace is 2 cubic meters, and 200 semi-finished cast iron pots of 32 cm can be placed in it at one time. Use a vacuum pump The air with a volume fraction of 85% is pumped out...

Embodiment 3

[0034] Choose No. 22 cast iron as the raw material, and use ordinary technology to smelt it at a temperature of 800-900 ° C. After smelting, it will be processed into a pot semi-finished product according to the shape of the pot according to the existing method of casting and processing pots, and then through ordinary sanding. The equipment sands off the oxide skin on the surface of the semi-finished cast iron pot and removes the dust on the surface. Use ordinary grinding equipment to grind the mouth of the semi-finished cast iron pot into a rounded corner, and drill holes for the handle on the side of the semi-finished cast iron pot.

[0035] Put the above-mentioned semi-finished cast iron pots after drilling into a vacuum nitriding furnace with good sealing performance. The space of the vacuum nitriding furnace is 2 cubic meters, and 200 semi-finished cast iron pots of 32 cm can be placed in it at one time. Use a vacuum pump The air with a volume fraction of 80% is extracted....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com