Semi-dry flame-retardant anti-corrosion adhesive tape and preparation method thereof

An anti-corrosion, semi-dry technology, used in textiles and papermaking, etc., can solve the problems of difficult discharge of corrosive media, loss of protection, waste of human and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A semi-dry flame-retardant and anti-corrosion adhesive tape provided in Embodiment 1 of the present invention includes the following raw materials in mass percentage: 8-12% of flame-retardant non-woven fabric, 44-57% of base oil, 8-12% of silicone resin, gas phase dioxide Silicon 5-8%, pyrophyllite powder 8-12%, brucite powder 6-10%, metal corrosion inhibitor 3-6%.

[0028]Among them, the flame-retardant non-woven fabric is the main material of the semi-dry flame-retardant and anti-corrosion adhesive tape of the embodiment of the present invention. The flame-retardant non-woven fabric has the characteristics of non-combustibility, non-toxic and non-irritating, and is a flame-retardant material with excellent performance. However, flame-retardant non-woven fabrics have defects such as unreliable bonding with metal surfaces, poor sealing effect, and inability to completely block oxygen. Just in order to solve this defect, the semi-dry flame-retardant and anti-corrosion ad...

Embodiment 2

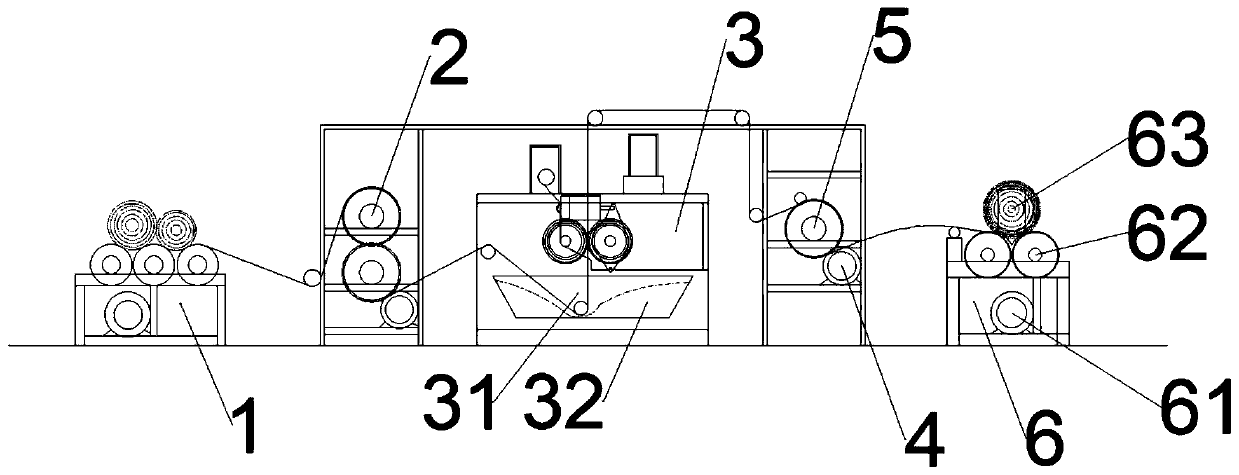

[0050] Based on the same inventive idea, refer to figure 1 As shown, Embodiment 2 of the present invention provides a method for preparing the semi-dry flame-retardant and anti-corrosion adhesive tape provided in Embodiment 1 above, the method comprising:

[0051] Step 1: Add base oil and silicone resin into the planetary stirring tank, stir and heat up to 100°C~120°C, dehydrate for 30min~40min, then cool down to 90°C, then add fumed silica, pyrophyllite powder, and brucite powder into the planetary stirring tank Stir in the stirring tank at high speed for 60-90 minutes; then add the metal corrosion inhibitor and continue stirring for 20-40 minutes to obtain the leaching material mixture, wherein the base oil includes 35-45% by mass of bran oil, 4-6% of Soy lecithin and 5-7% hydrogenated castor oil derivatives.

[0052] It should be noted that the planetary stirring tank is also called the planetary mixer, which is a new type of high-efficiency non-dead point mixing equipment...

Embodiment 3

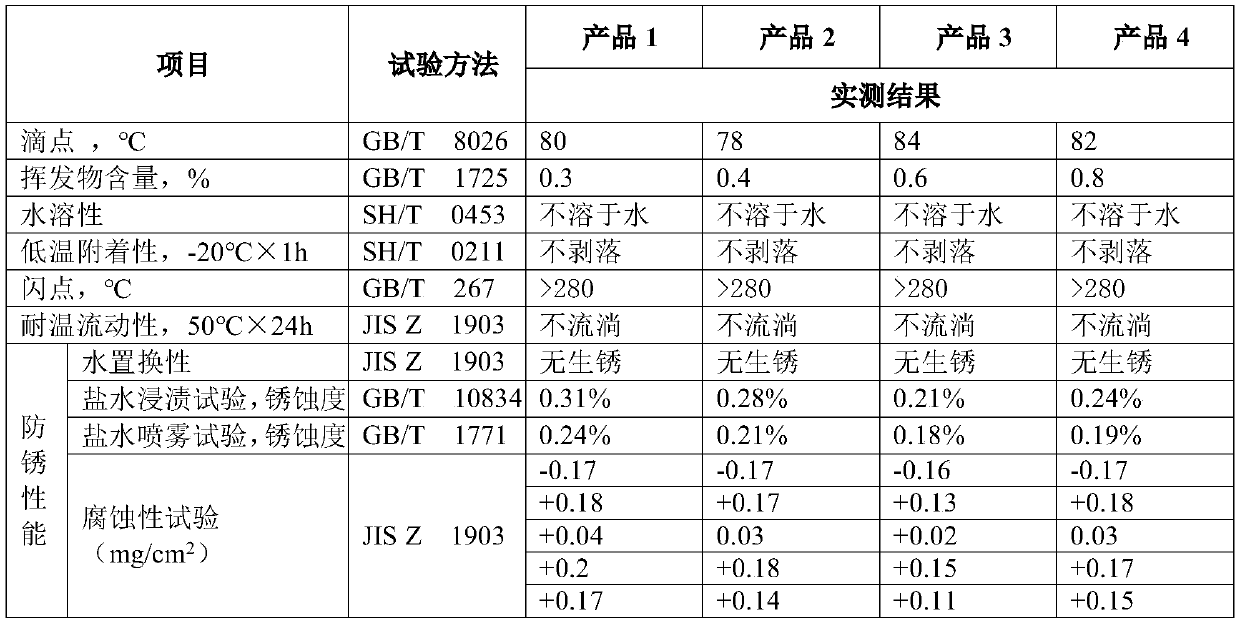

[0059] Embodiment 3 of the present invention will analyze the performance of the semi-dry flame-retardant and anti-corrosion adhesive tape provided by the above-mentioned embodiment 1 and the above-mentioned embodiment 2 by means of specific experiments. Through comparative analysis, it is found that the semi-dry flame-retardant The anti-corrosion adhesive tape has a long-term and durable anti-corrosion protection function. The anti-corrosion layer has a dense insulation, good permeability, and strong ability to chelate and rust. First of all, this product can be used in the temperature range of -30°C to +120°C, and has permanent adhesion to metal structures, because the soft structure of the anti-corrosion protection layer formed by this product can absorb and decompose stress, even in the long-term The surface of the vibrating metal structure is always adhered to its surface; secondly, the anti-corrosion layer formed by this product is dense, has good insulation performance, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com