Method for refining dibasic acid dimethyl ester plasticizer

A technology of dimethyl dibasic acid and refining method, which is applied in the refining field of aliphatic dibasic acid dimethyl ester plasticizer, can solve the problem of unstable impurity content and acid value, inability to further recover monoester, and poor product quality. Stability and other issues, to achieve the effect of clear segmentation, increased variety, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

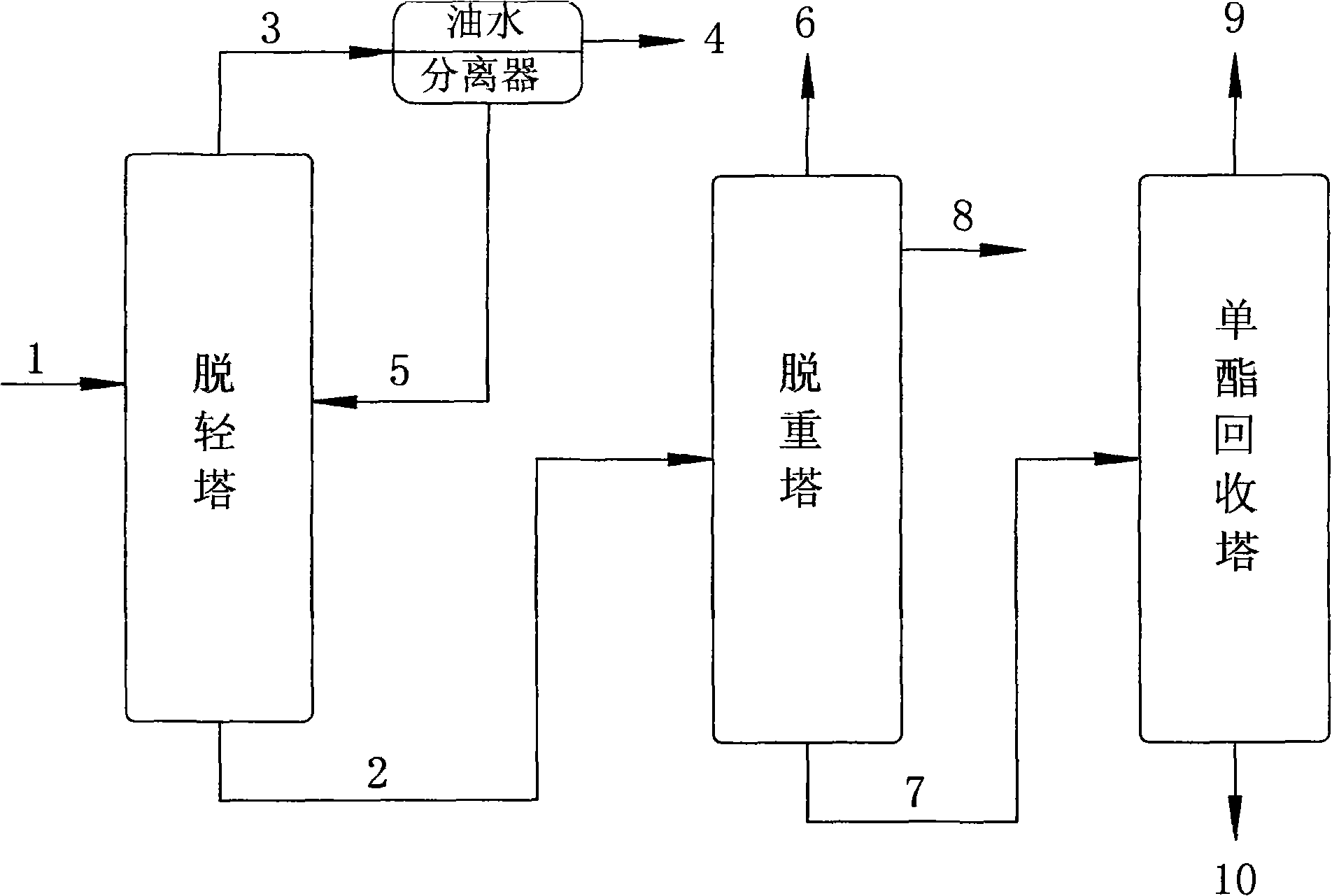

[0023] As shown in the attached figure, the crude plasticizer synthesized from nylon acid (containing succinic acid, glutaric acid and adipic acid) obtained from the mother liquor of adipic acid is used as raw material, and the crude plasticizer contains methanol 2% by weight, 1% by weight of water, 80% by weight of dimethyl dibasic acid, 14% by weight of monomethyl ester, 2% by weight of impurities such as tar, etc. The crude plasticizer 1 enters the light removal tower after being filtered. The light removal tower is operated under reduced pressure, the operating pressure is 20kPa, and the operating temperature at the top of the tower is 120°C. The gas phase light component 3 is removed by the light removal tower. The light component 3 is mainly composed of methanol, water and dimethyl succinate. After condensation, it enters the oil-water separator and is divided into two liquid phases. Methanol and water 4 are in the upper layer It is the water phase, and the dimethyl suc...

Embodiment 2

[0026] As shown in the attached figure, the crude plasticizer synthesized from nylon acid (containing succinic acid, glutaric acid and adipic acid) obtained from the mother liquor of adipic acid is used as raw material, and the crude plasticizer contains methanol 2% by weight, 1% by weight of water, 80% by weight of dimethyl dibasic acid, 14% by weight of monomethyl ester, 2% by weight of impurities such as tar, etc. The crude plasticizer 1 enters the light removal tower after being filtered. The light removal tower is operated under reduced pressure, the operating pressure is 10kPa, and the operating temperature at the top of the tower is 104°C. The gas phase light component 3 is removed by the light removal tower. The light component 3 is mainly composed of methanol, water and dimethyl succinate. After condensation, it enters the oil-water separator and is divided into two liquid phases. Methanol and water 4 are in the upper layer It is the water phase, and the dimethyl suc...

Embodiment 3

[0029]The process steps are the same as in Example 2, except that the weight-removing tower is provided with two side lines, the reflux ratio is 1.0, and the plasticizer product at the top of the weight-removing tower contains: 34% by weight of dimethyl succinate, 64% by weight of dimethyl glutarate , dimethyl adipate 1% by weight, monoester total content 1ppm, the plasticizer product that the lower part extracts from the side line at 15 theoretical plates contains: dimethyl succinate 3% by weight, dimethyl glutarate 21 % by weight, 75% by weight of dimethyl adipate, 10ppm of total monoester content, and the upper part contains 25% by weight of dimethyl succinate, dimethyl glutarate, and 40 theoretical boards. 52% by weight of ester, 22% by weight of dimethyl adipate, and a total monoester content of 20ppm. After the above process, three grades of plasticizers are obtained. Impurities such as methanol and water are below 1ppm, and the content of monomethyl ester is 20ppm. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com